Oil-water separation type fryer

A technology of oil-water separation and deep fryer, which is applied to the utensils for frying things in oil, household utensils, applications, etc., which can solve the problems of high use cost, unfavorable long-term use of edible oil, and large amount of edible oil, etc., to achieve The effect of many times of use, convenient installation and long use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

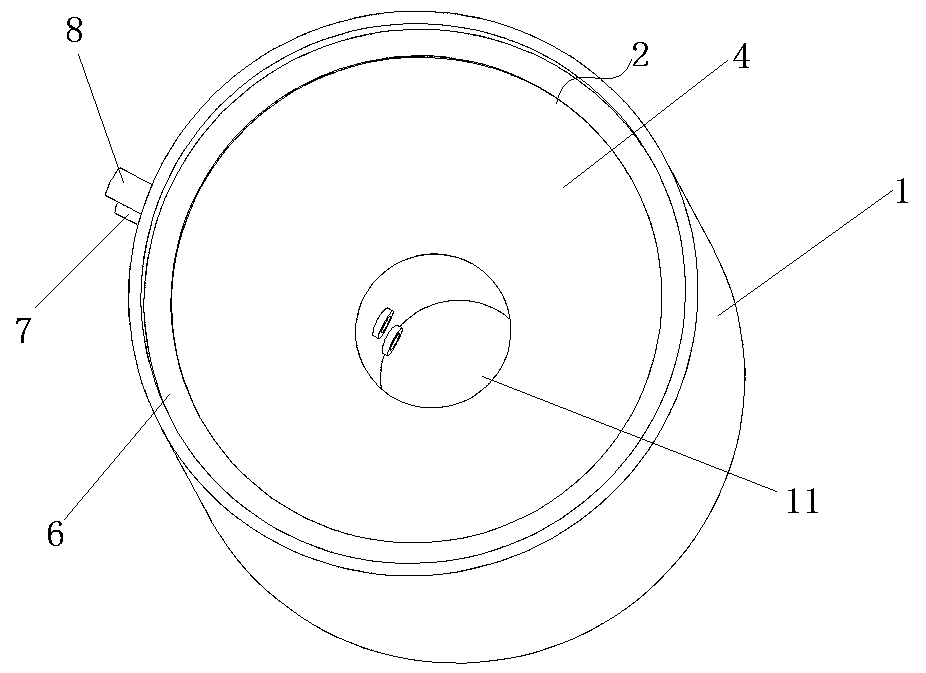

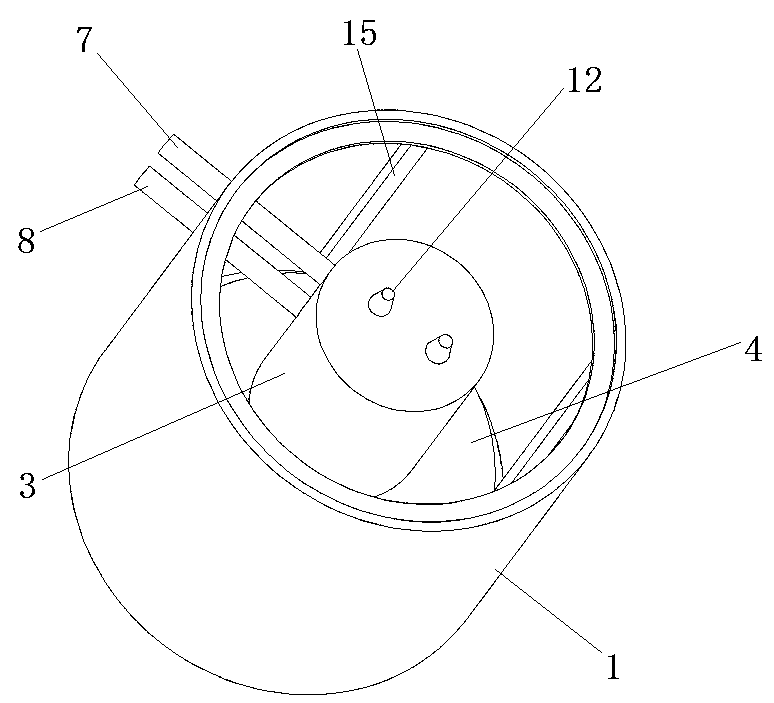

[0039] Such as Figure 1 to Figure 7 As shown, the oil-water separation fryer is made of stainless steel and includes a cylindrical shell 1 with a hollow structure. The inner wall of the shell 1 is evenly welded with vertical beams extending axially along the circumference of the shell 1. 15 (reference figure 2 and Figure 5 ), the vertical beam 15 is a rectangular tube.

[0040] The housing 1 is provided with a pot liner 2, such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the inner pot 2 is composed of two parts, namely a pot body 4 and a cylinder body 3 connected to the bottom of the pot body 4 . Wherein, the inner surface of the pot body 4 is a circular arc surface, which is closed from top to bottom, with the largest diameter at the top and the smallest inner diameter at the bottom. Seen from the figure, the top opening edge of the pot body 4 is integrally formed with a circle of turning edge 6 extending radially of the pot body 4, and the turning ed...

Embodiment 2

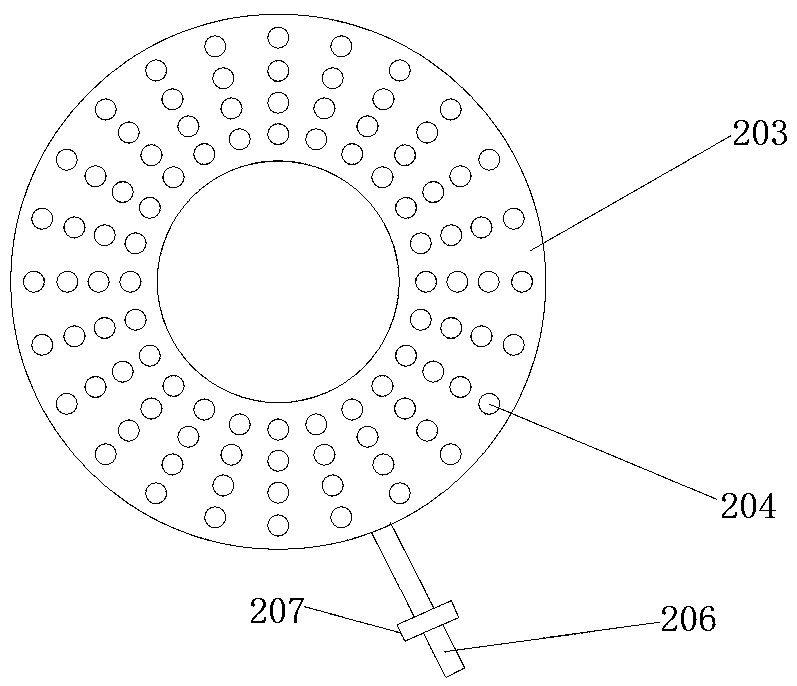

[0051] Such as Figure 8 and Figure 9 As shown, the difference between this embodiment and the above-mentioned embodiment 1 is that in this embodiment, the heating assembly is a liquefied gas heating assembly, and the liquefied gas heating assembly is a stove plate 203. Avoid the escape hole of the cylinder body, the cylinder body passes through the avoidance hole so that the stove plate 203 is sleeved outside the cylinder body 201, and is located under the pot body 202, and the stove plate 203 is provided with an air inlet pipe communicating with the liquefied gas source 206 , the inlet pipe 206 is provided with an inlet valve 207 for controlling on-off of the liquefied gas, and the valve 207 is located outside the casing 205 . The upper part of the stove 203 is provided with fire outlets 204 distributed in a circle, and the casing 205 is provided with an ignition switch (not shown in the figure) for controlling the switch of the stove 203, and turning the ignition switch c...

Embodiment 3

[0054] The difference between this embodiment and the above-mentioned embodiment 1 is that in this embodiment, the inner surface of the pot body is a conical surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com