Normal temperature yogurt without stabilizer and preparation method thereof

A technology of stabilizer and room temperature, which is applied to the field of room temperature yogurt without stabilizer and its preparation, can solve the problems of containing and other problems, and achieve the effects of rich nutrition, stable taste and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

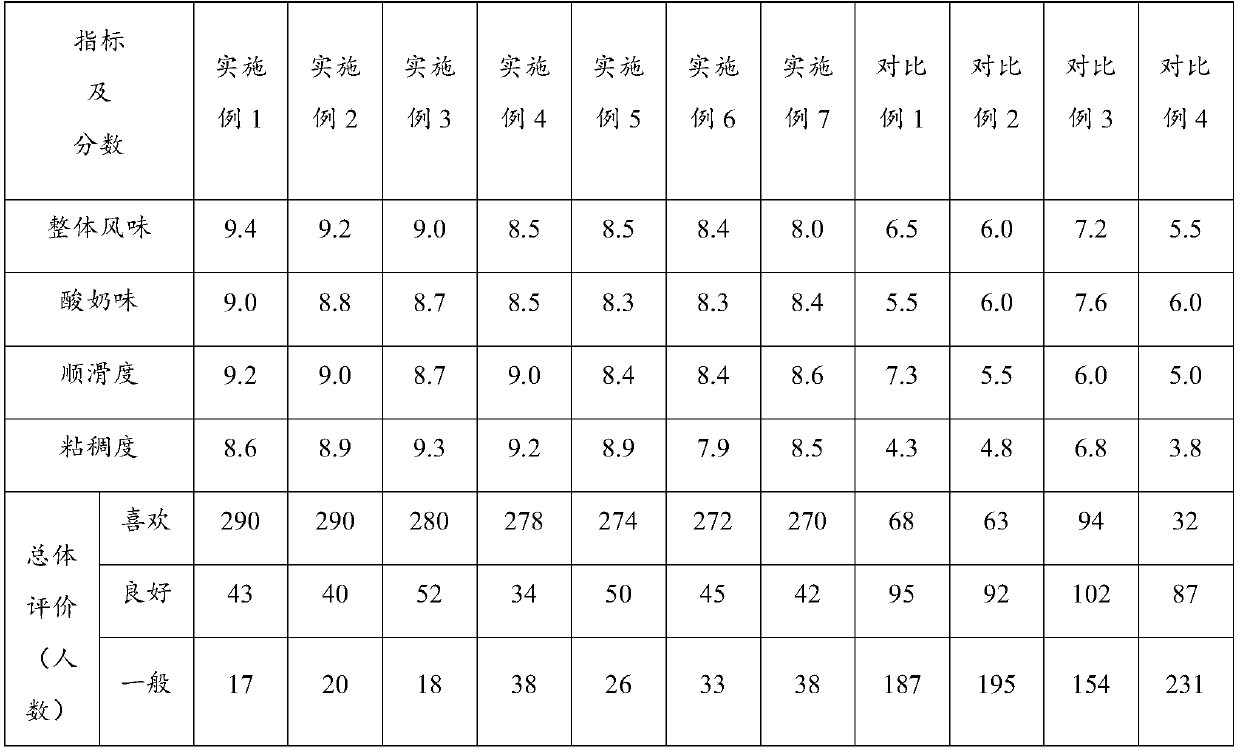

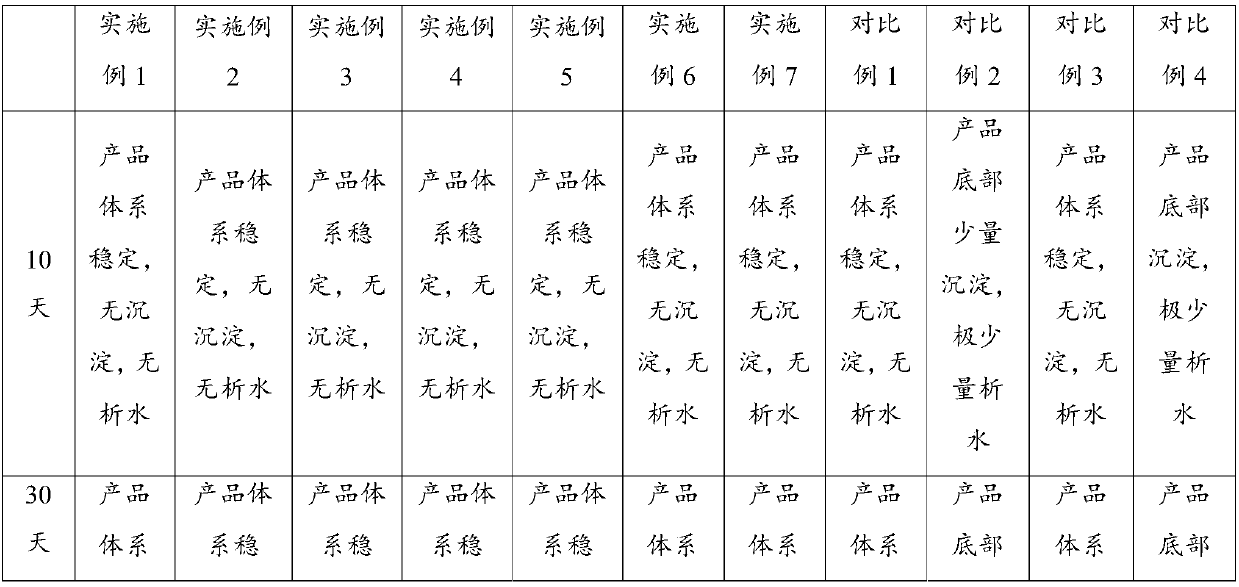

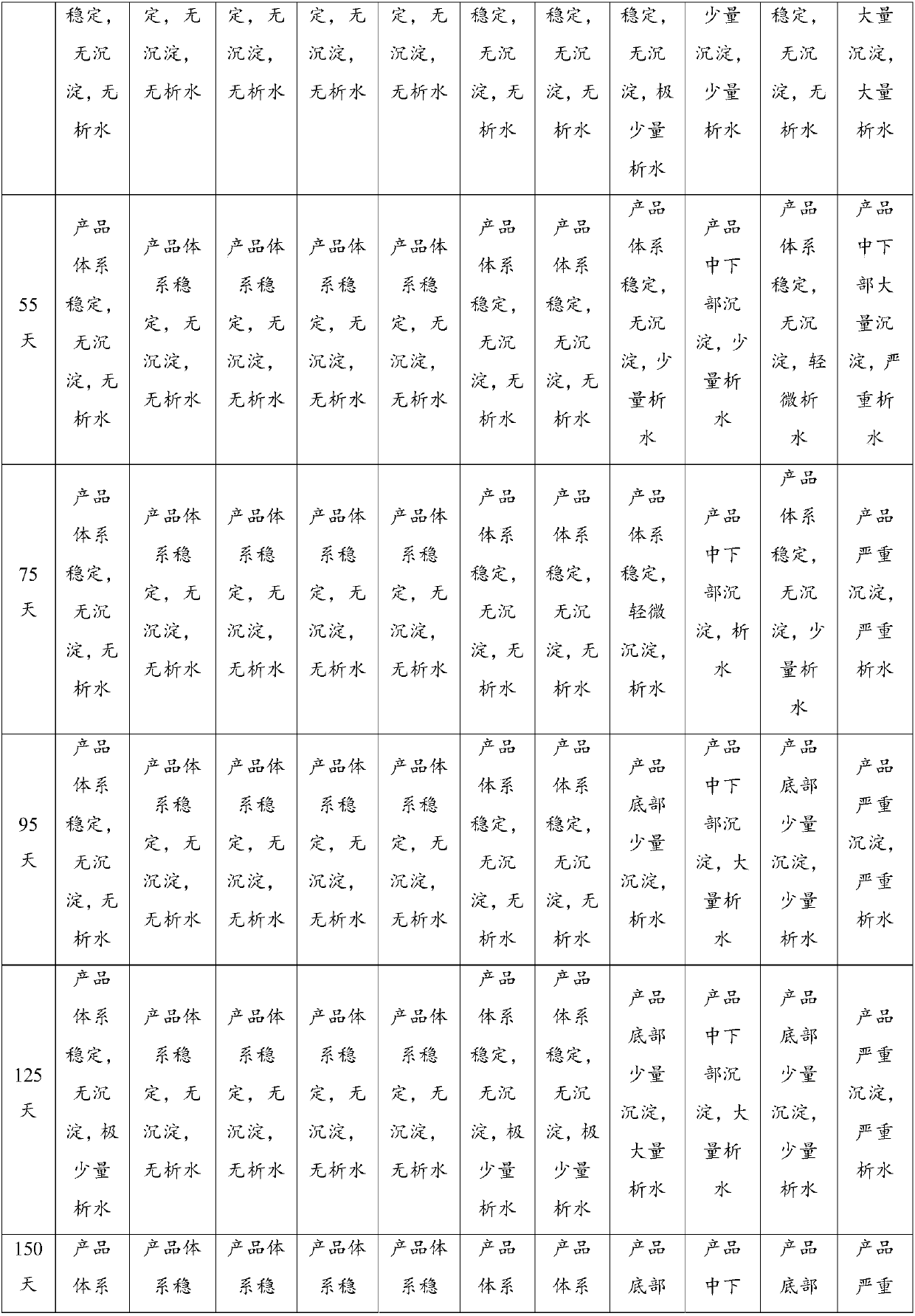

Examples

Embodiment 1

[0045] The present embodiment provides a kind of room temperature yogurt without stabilizer, and its raw material composition is as follows:

[0046] 1. Raw materials (calculated by 1000 kg)

[0047] Milk: 900kg

[0048] Fructose syrup: 90 kg

[0049] Fairy grass powder: 10kg

[0050] Starter: 100U / T.

[0051] 2. Preparation method

[0052] 2.1 Heat the high-quality raw milk with a protein content of 3.1% to 55°C, and dissolve the heated milk and the grass powder in a mass ratio of 50:1 through a high-speed shearing machine, and the speed of the high-speed shearing machine is 1400 rpm / minutes, dissolve for 15 minutes;

[0053] 2.2 Hydrate the dissolved feed liquid for 15 minutes, and the stirring speed is at 80 rpm;

[0054] 2.3 Add the remaining milk and fructose syrup to the hydrated feed liquid, keep the feed liquid at 55°C, and homogenize it by a high-pressure homogenizer with a homogenization pressure of 25Mpa;

[0055] 2.4 Sterilize the homogenized feed liquid, t...

Embodiment 2

[0061] The present embodiment provides a kind of room temperature yogurt without stabilizer, and its raw material composition is as follows:

[0062] 1. Raw materials (calculated by 1000 kg)

[0063] Milk: 910kg

[0064] White sugar: 70kg

[0065] Fairy grass powder: 20kg

[0066] Starter: 100U / T.

[0067] 2. Preparation method

[0068] 2.1 Heat the high-quality fresh milk with a protein content of 3.1% to 60°C, and dissolve the heated milk and the grass powder in a mass ratio of 55:1 through a high-speed shearing machine, and the speed of the high-speed shearing machine is 1600 rpm , dissolve for 15 minutes;

[0069] 2.2 Hydrate the dissolved feed liquid for 20 minutes;

[0070] 2.3 Add the remaining milk and white sugar to the hydrated feed liquid, keep the feed liquid at 60°C, and homogenize it by a high-pressure homogenizer with a homogenization pressure of 28Mpa;

[0071] 2.4 Sterilize the homogenized feed liquid, the sterilization temperature is 100°C, and the tim...

Embodiment 3

[0077] The present embodiment provides a kind of room temperature yogurt without stabilizer, and its raw material composition is as follows:

[0078] 1. Raw materials (calculated by 1000 kg)

[0079] Milk: 890kg

[0080] White sugar: 80kg

[0081] Fairy grass powder: 30kg

[0082] Starter: 100U / T.

[0083] 2. Preparation method

[0084] 2.1 Heat the high-quality raw milk with a protein content of 3.2% to 65°C, and dissolve the heated milk and the grass powder in a mass ratio of 60:1 through a high-speed shearing machine. The speed of the high-speed shearing machine is 2000 rpm / minutes, dissolve for 20 minutes;

[0085] 2.2 Hydrate the dissolved feed liquid for 20 minutes;

[0086] 2.3 Add the remaining milk and white sugar to the hydrated feed liquid, keep the feed liquid at 65°C, and homogenize it by a high-pressure homogenizer with a homogenization pressure of 32Mpa;

[0087] 2.4 Sterilize the homogenized feed liquid, the sterilization temperature is 105°C, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com