Heteroatom doped carbon/CoS2 functional material derived based on metal organic framework and application thereof

A technology of metal-organic frameworks and functional materials, applied in electrochemical generators, secondary battery repair/maintenance, electrical components, etc., can solve the problem of unfavorable solid electrolyte stable formation, hindering the widespread application of lithium-sulfur batteries, and deteriorating lithium dendrite growth and other problems, to achieve the effects of suppressing the shuttle effect, improving performance, and improving cycle and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of ZIF8 / ZIF67 composite structure

[0046] Take zinc nitrate hexahydrate and dimethylimidazole with a mass ratio of 1:1 and dissolve them in 100 ml of methanol solution respectively to form liquids A and B. Slowly add liquid B to liquid A, keep stirring for 24 hours, and then 60 Vacuum drying at ℃ for 12 hours to obtain ZIF8; take a certain amount of ZIF8 and disperse it in 100 ml of methanol, add cobalt nitrate hexahydrate and dimethylimidazole at a mass ratio of 1:1, and the mass ratio of ZIF8 and cobalt nitrate hexahydrate is 1:7, The reaction was kept under stirring for 24 h at room temperature, and then vacuum-dried at 60° C. for 12 h to obtain a ZIF8 / ZIF67 composite structure.

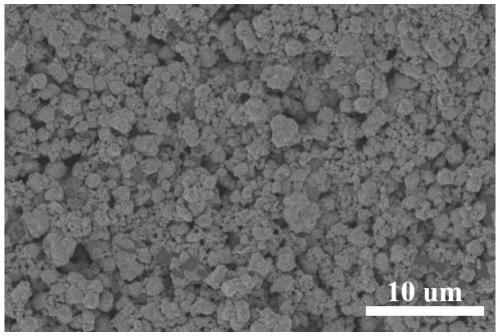

[0047] 2. Preparation of CoS 2 / C-1 structure

[0048] Put the product ZIF8 / ZIF67 in a crucible, then place it in a tube furnace, heat it to 700°C and keep it for 4h, the heating rate is 4°C / min, and the carbonized product is obtained after natural cooling; Weigh the mass ...

Embodiment 2

[0054] 1. Preparation of ZIF8 / ZIF67 structure

[0055] Take zinc nitrate hexahydrate and dimethylimidazole with a mass ratio of 1:1 and dissolve them in 100 ml of methanol solution respectively to form liquids A and B. Slowly add liquid B to liquid A, keep stirring for 24 hours, and then 60 Vacuum drying at ℃ for 12 hours to obtain ZIF8; take a certain amount of ZIF8 and disperse it in 100 ml of methanol, add cobalt nitrate hexahydrate and dimethylimidazole at a mass ratio of 1:1, and the mass ratio of ZIF8 and cobalt nitrate hexahydrate is 1:10, The reaction was kept stirring at room temperature for 24 h, and then vacuum-dried at 60° C. for 12 h to obtain ZIF8 / ZIF67.

[0056] 2. Preparation of CoS 2 / C-1 structure

[0057] The product ZIF8 / ZIF67 was placed in a crucible, then placed in a tube furnace, heated to 900°C and kept for 2 hours, and the carbonized product was obtained after natural cooling; the carbonized product and sublimed sulfur with a mass ratio of 1:10 were ...

Embodiment 3

[0063] 1. Preparation of LDH / ZIF67

[0064] Dissolve cobalt chloride hexahydrate, aluminum chloride hexahydrate and urea with a mass ratio of 2:1:1.5 in 500 mL of deionized water, raise the temperature to 90°C, keep stirring for 12 hours, collect the product by centrifugation, and dry it in vacuum at 80°C for 6 hours. Obtain LDH; take a certain amount of LDH (mass ratio LDH: cobalt nitrate hexahydrate = 1:6) and disperse it in 100mL of methanol, add cobalt nitrate hexahydrate and dimethylimidazole with a mass ratio of 2:1, and keep stirring at room temperature 0.5-4h, the reaction product was dried at 80°C for 8h to obtain LDH / ZIF67.

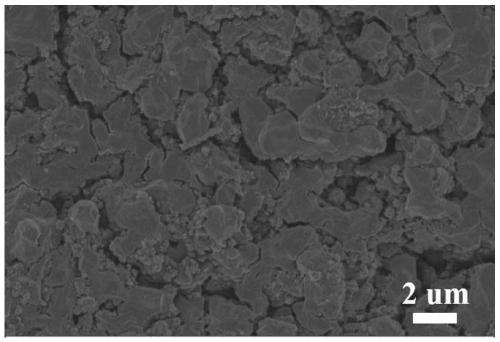

[0065] 2. CoS 2 Preparation of / C-2

[0066] Put the product LDH / ZIF67 obtained in step 1 in a porcelain boat, then place it in a tube furnace, program the temperature to 900°C and keep it for 2 hours, the heating rate is 5°C / min, and obtain the carbonized product after natural cooling; the mass ratio is weighed as The 6:1 sublimated sulfur a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com