A special flame-retardant cable production process for LED lighting and its production equipment

A technology of LED lighting and production equipment, which is applied in the direction of electrical components, circuits, conductor/cable supply devices, etc. It can solve the problem of reducing the sealing of the extrusion die or the connection between the die and the extruder head, easy slipping of the locking screw, Unfavorable production efficiency and other issues, to achieve the effect of reducing the difficulty of operation, convenient locking, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

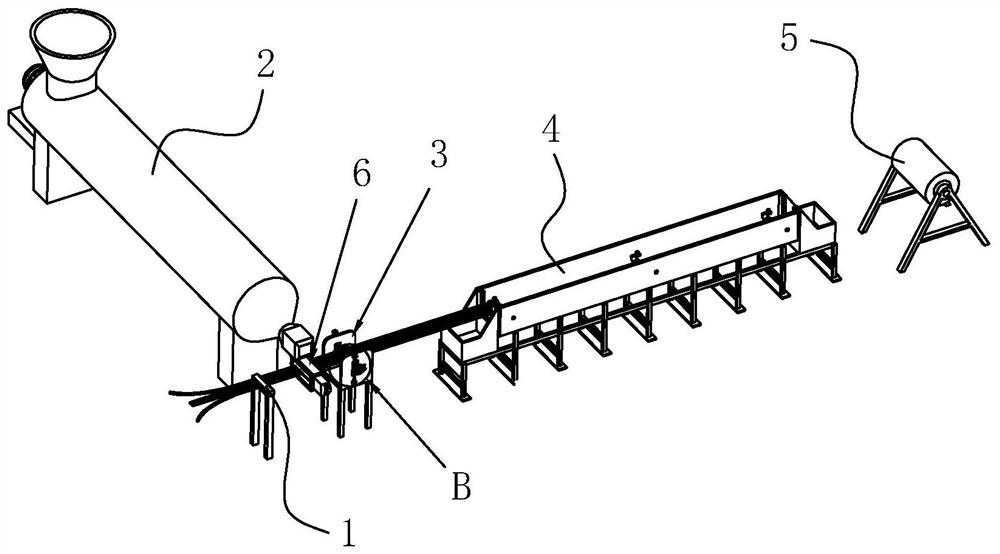

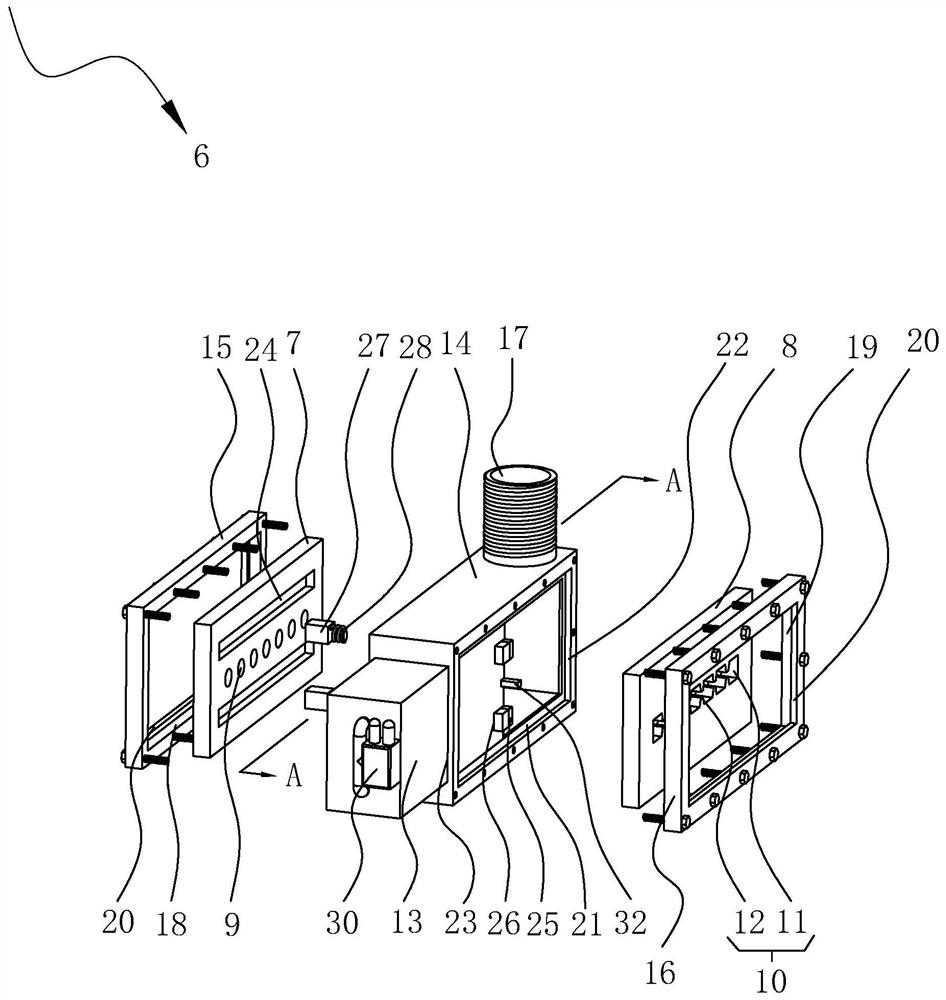

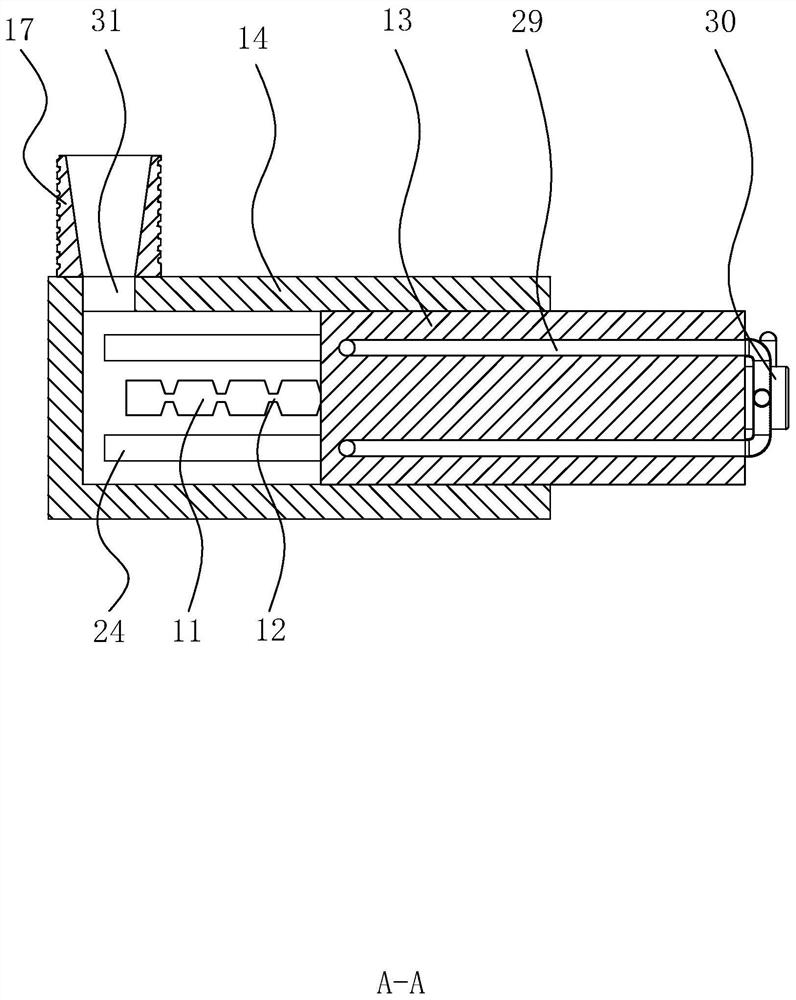

[0042] refer to figure 1 with figure 2 , which is a special flame-retardant cable production process for LED lighting and its production equipment disclosed in the present invention, the production equipment includes a cable machine 1, an extruder 2, a calibration machine 3, a cooling device 4 and a winding device arranged in sequence 5. The cable arrangement machine 1 is used to arrange multiple wires into strips, the calibration machine 3 is used to calibrate the extruded flame-retardant cable, and the cooling device 4 is used to cool and shape the calibrated cable Air-drying, cable machine 1, extruder 2, cooling device 4 and winding device 5 are all common technical means in the art, and will not be repeated here; the head of extruder 2 is detachably provided with an extrusion die 6. The extrusion die 6 is a hollow cuboid and is threadedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com