Preparation method for low-alloyed high-strength plastic magnesium alloy material

A magnesium alloy and low alloy technology, applied in the field of magnesium alloy material preparation, can solve the problems of high temperature deformation energy consumption, inability to guarantee strength and plasticity at the same time, and high alloy cost, so as to improve mechanical properties, overcome inclusions and entrainment oxidation , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

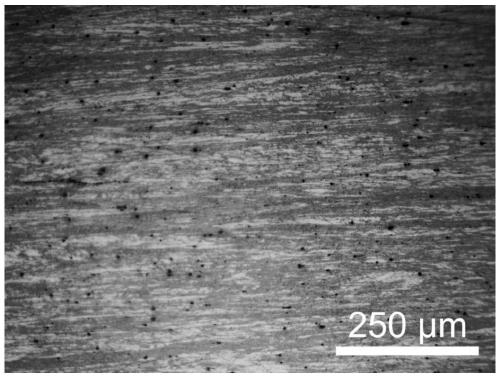

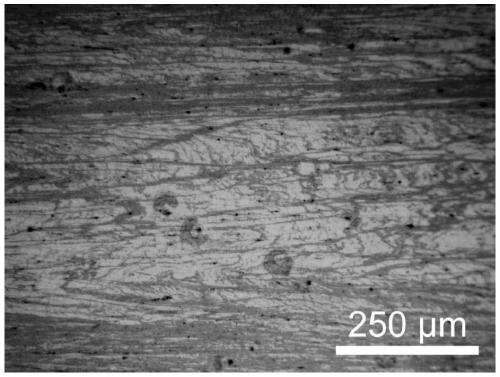

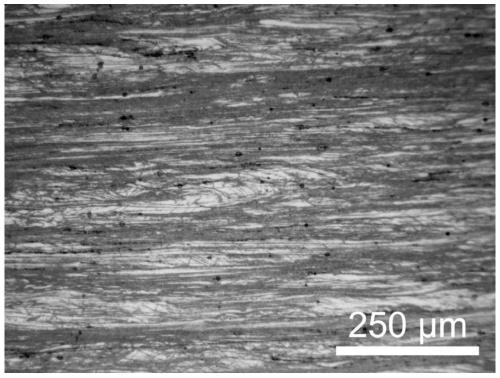

Image

Examples

specific Embodiment approach 1

[0029] Specific implementation mode 1: This implementation mode is a preparation method of a low-alloyed high-strength plastic magnesium alloy material, which is specifically carried out according to the following steps:

[0030] 1. Heat the pure magnesium block to 750°C~760°C in a protective atmosphere to reach a molten state. After the pure magnesium block is completely melted, add preheated Zn grains and preheated Mg-Y master alloy at the same time to obtain a ternary alloy Melt, vortex-free homogenization treatment for 3 minutes to 5 minutes to promote the uniform distribution of alloying elements. After non-eddy current homogenization treatment, evenly sprinkle a layer of covering agent on the surface of the molten metal to protect the molten metal from contact with air. The temperature is 720°C Stand at ~750°C for 10min-15min, add refining agent, refine the molten metal for 30s-40s at a temperature of 720°C-750°C and without eddy current homogenization treatment, and then...

specific Embodiment approach 2

[0037] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the protective atmosphere described in step one is CO 2 with SF 6 The mixed gas, where SF 6 The volume fraction is 5% to 6%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0038]Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, there is no vortex homogenization treatment for 3 minutes to 5 minutes to promote the uniform distribution of alloying elements. The stirring rate is 50 rpm to 100 rpm, and it is clockwise mechanical stirring . Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com