A kind of alkali-free aluminoborosilicate glass and preparation method thereof

A borosilicate glass, alkali aluminum technology, applied in glass manufacturing equipment, glass molding, manufacturing tools and other directions, can solve problems such as non-compliance with environmental protection requirements, and achieve enhanced glass network structure, easy acquisition, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

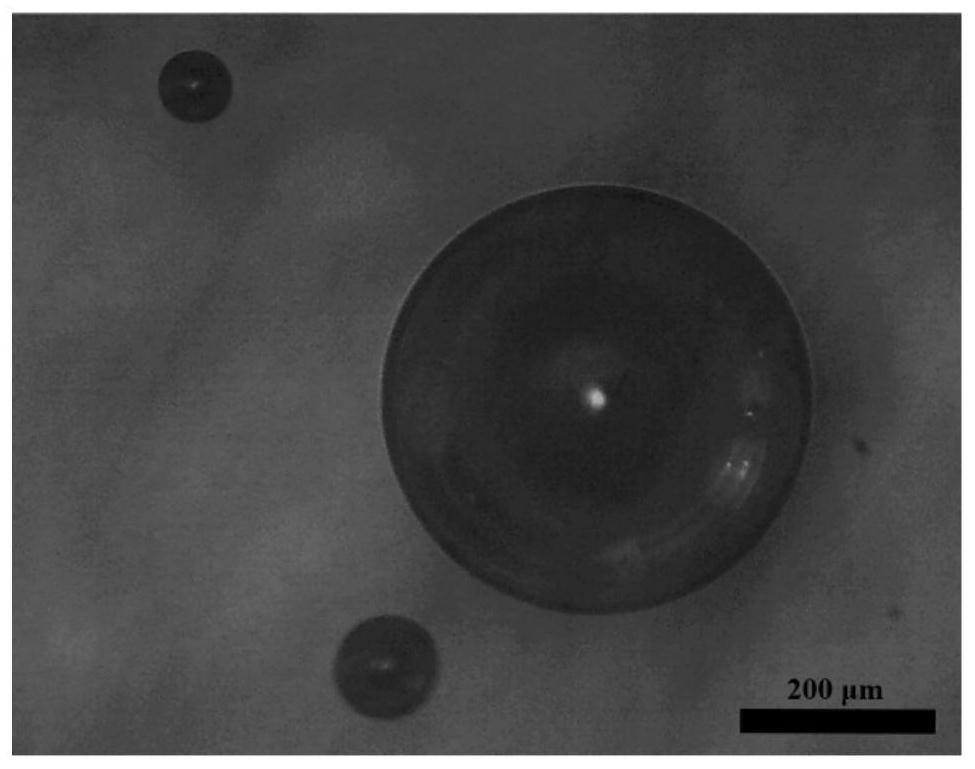

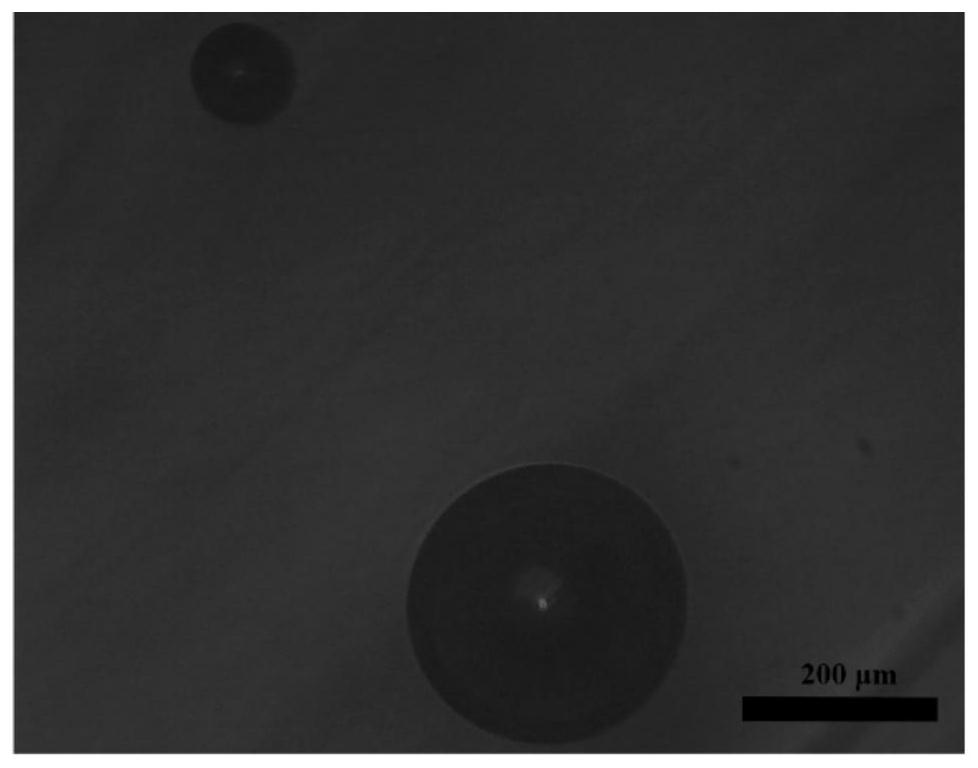

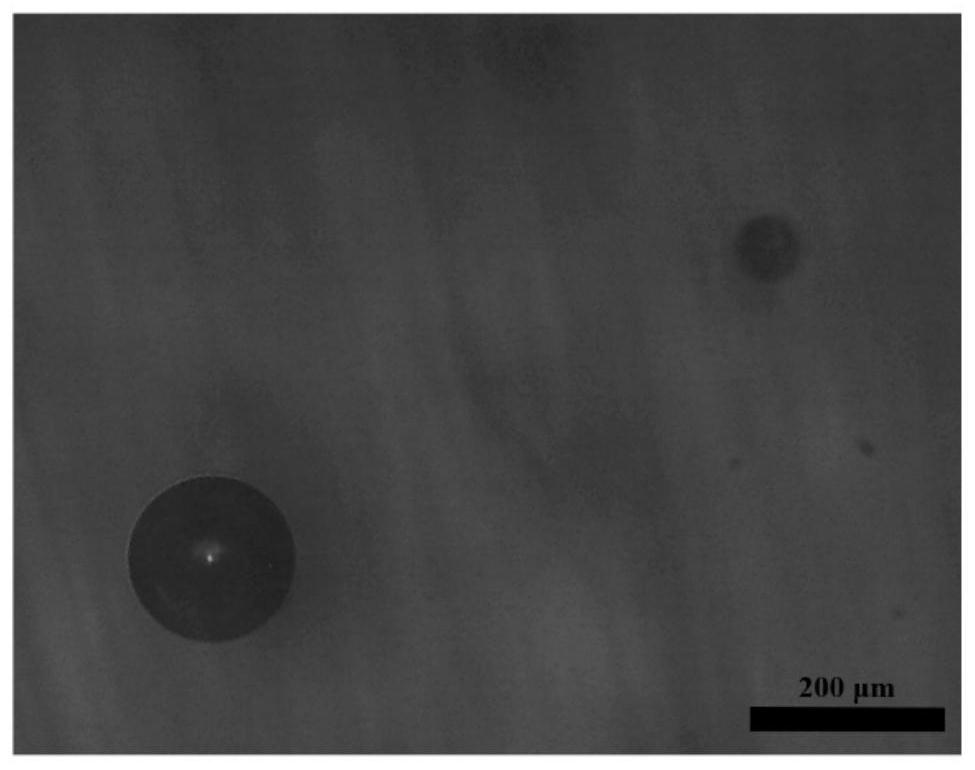

Image

Examples

Embodiment 1

[0040] A kind of alkali-free aluminoborosilicate glass, the mass percentage of glass is: 60.0wt% SiO 2 , 19 wt% Al 2 o 3 , 5.5 wt% B 2 o 3 , 2.0wt%P 2 o 5 , 2.5wt% MgO, 5.5wt% CaO, 5.0wt% SrO, 0.5wt% ZnO, plus 0.2wt% SnO of the total weight of raw materials 2 .

[0041] The preparation method of glass comprises the following steps: 1) calculating the mass fraction of batch materials and the corresponding raw material consumption according to the mass fractions of the above-mentioned oxides, and accurately weighing each raw material according to the proportion; 2) pouring the glass raw material obtained in step 1 into a mortar 3) Put the mixed glass batch into a corundum crucible or platinum crucible or a melting pool, and then melt it at a high temperature of 1650-1680°C for 3 hours; 4) Pour the uniformly melted high-temperature glass liquid into the preheated It is formed in a stainless steel mold, and then transferred to a muffle furnace at 680°C for annealing for 3 h...

Embodiment 2

[0044] A kind of alkali-free aluminoborosilicate glass, the mass percentage of glass is: 60.0wt% SiO 2 , 17.5 wt% Al 2 o 3 , 4.0 wt% B 2 o 3 , 5.0wt%P 2 o 5 , 2.0wt% MgO, 6.0wt% CaO, 5.0wt% SrO, 0.5wt% ZnO, plus 0.2wt% SnO 2 .

[0045] The preparation method of glass comprises the following steps: 1) calculating the mass fraction of batch materials and the corresponding raw material consumption according to the mass fractions of the above-mentioned oxides, and accurately weighing each raw material according to the proportion; 2) pouring the glass raw material obtained in step 1 into a mortar 3) Put the mixed glass batch into a corundum crucible or platinum crucible or a melting pool, and then melt it at a high temperature of 1650-1680°C for 3 hours; 4) Pour the uniformly melted high-temperature glass liquid into the preheated It is formed in a stainless steel mold, and then transferred to a muffle furnace at 680°C for annealing for 3 hours to eliminate the thermal stres...

Embodiment 3

[0048] A kind of alkali-free aluminoborosilicate glass, the mass percentage of glass is: 60.0wt% SiO 2 , 13.5 wt% Al 2 o 3 , 8.0 wt% B 2 o 3 , 5.0wt%P 2 o 5 , 6.0wt% MgO, 4.0wt% CaO, 3.0wt% SrO, 0.5wt% ZnO, plus 0.4wt% SnO 2 .

[0049] The preparation method of glass comprises the following steps: 1) calculating the mass fraction of batch materials and the corresponding raw material consumption according to the mass fractions of the above-mentioned oxides, and accurately weighing each raw material according to the proportion; 2) pouring the glass raw material obtained in step 1 into a mortar 3) Put the mixed glass batch into a corundum crucible or platinum crucible or a melting pool, and then melt it at a high temperature of 1650-1680°C for 3 hours; 4) Pour the uniformly melted high-temperature glass liquid into the preheated It is formed in a stainless steel mold, and then transferred to a muffle furnace at 680°C for annealing for 3 hours to eliminate the thermal stres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com