Stamping die for computer keyboard

A technology for stamping dies and computer keyboards, applied in the field of stamping dies for computer keyboards, can solve problems such as difficulty in demolding, position deviation, and difficulty in taking out, and achieve the effects of avoiding the quality of stamping products, reducing demoulding damage, and uniform thrust force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

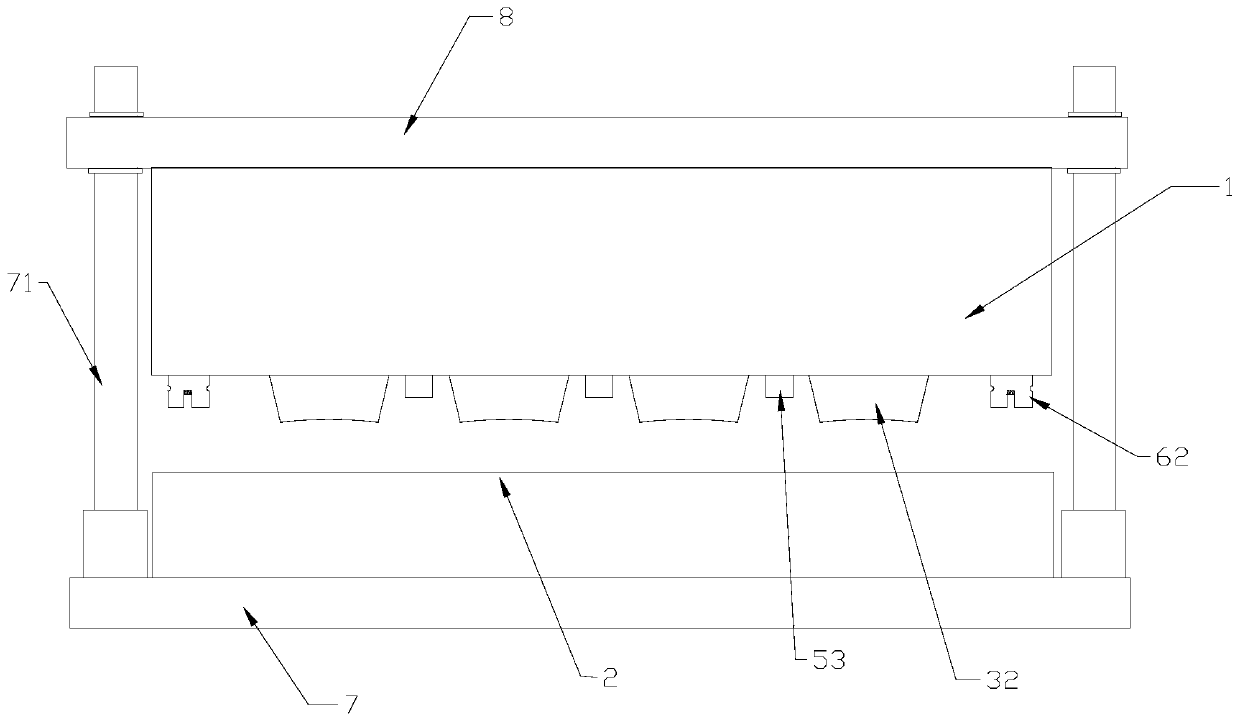

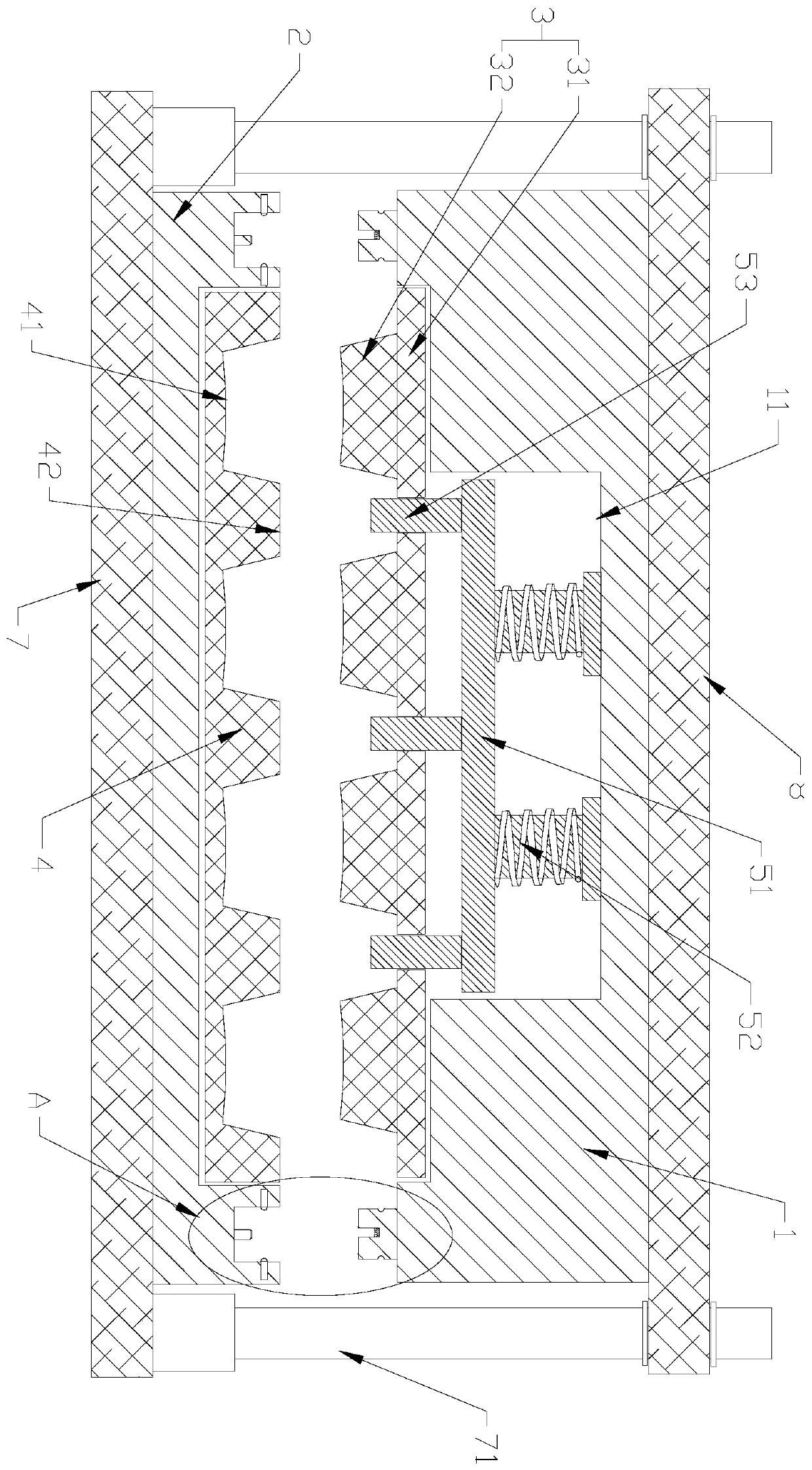

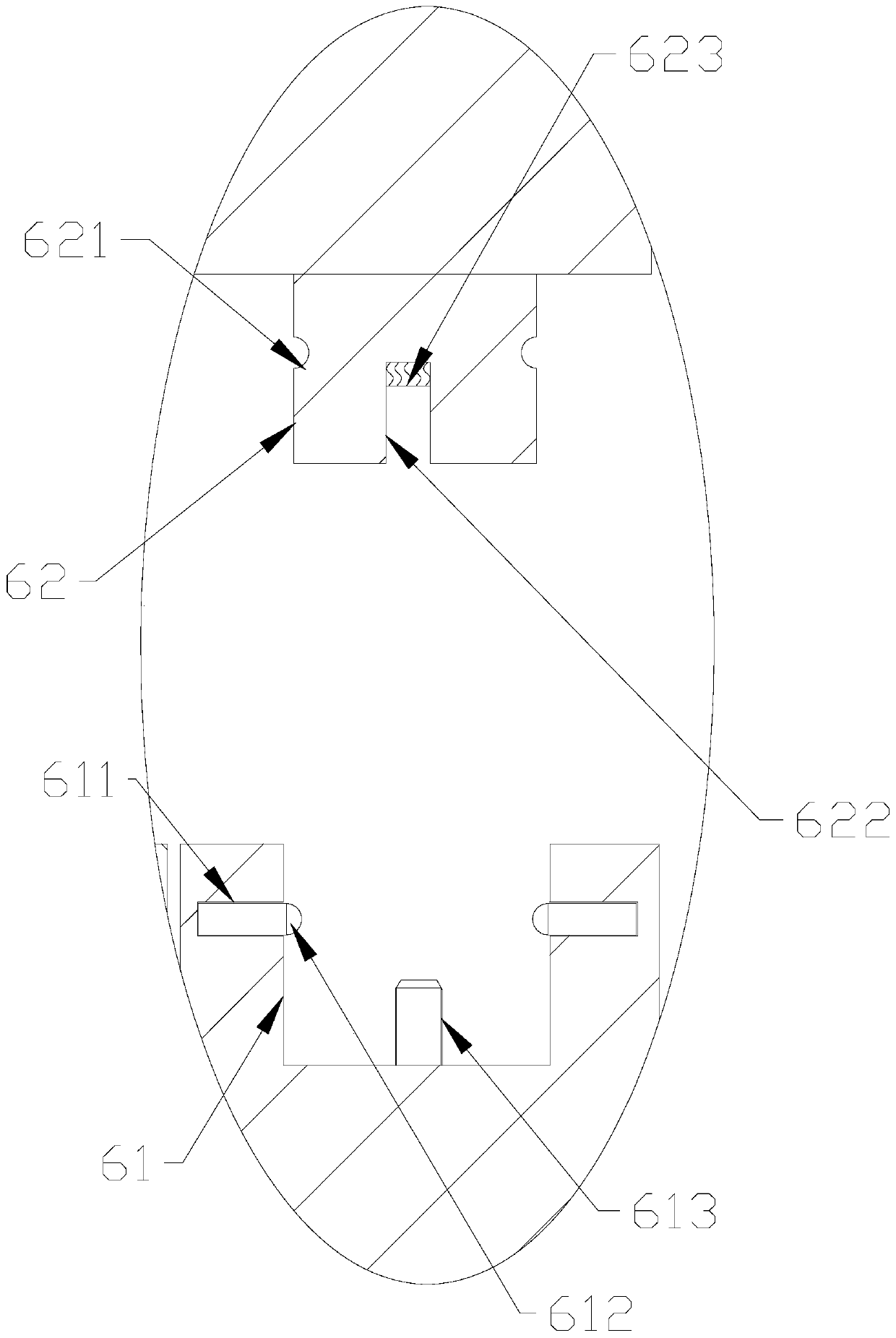

[0022] See attached Figure 1-2 As shown, a kind of stamping mold that is used for computer keyboard of the present invention comprises upper formwork 1, lower formwork 2 that are arranged oppositely, upper mold core 3 is installed on described upper formwork 1, and described lower formwork 2 is installed with The lower mold core 4 matched with the upper mold core 3 . The upper mold core 3 includes an upper mold core plate 31 , and a plurality of punching protrusions 32 matching the shape of the keyboard key grid are provided at the lower end of the upper mold core plate 31 . The upper mold plate 1 is provided with a groove 11 located at the upper end of the upper mold core plate 31 , and a push assembly for easy demoulding is arranged in the groove 11 . The push assembly includes a push plate 51 that can move up and down. The upper end of the push plate 51 is connected to the spring set 52 fixed in the groove 11, and the lower end is provided with a plurality of movable The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com