Dispensing method, bonding plate and crystal support for silicon wafer manufacturing

A bonding board and glue dispensing technology, which is applied to working accessories, manufacturing tools, fine working devices, etc., can solve the problems of high rate of defective products on the edge of silicon wafers, overflowing glue, bad glue layer, air bubbles, etc., to ensure the adhesion Add strength, eliminate bad product rate, avoid the effect of glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

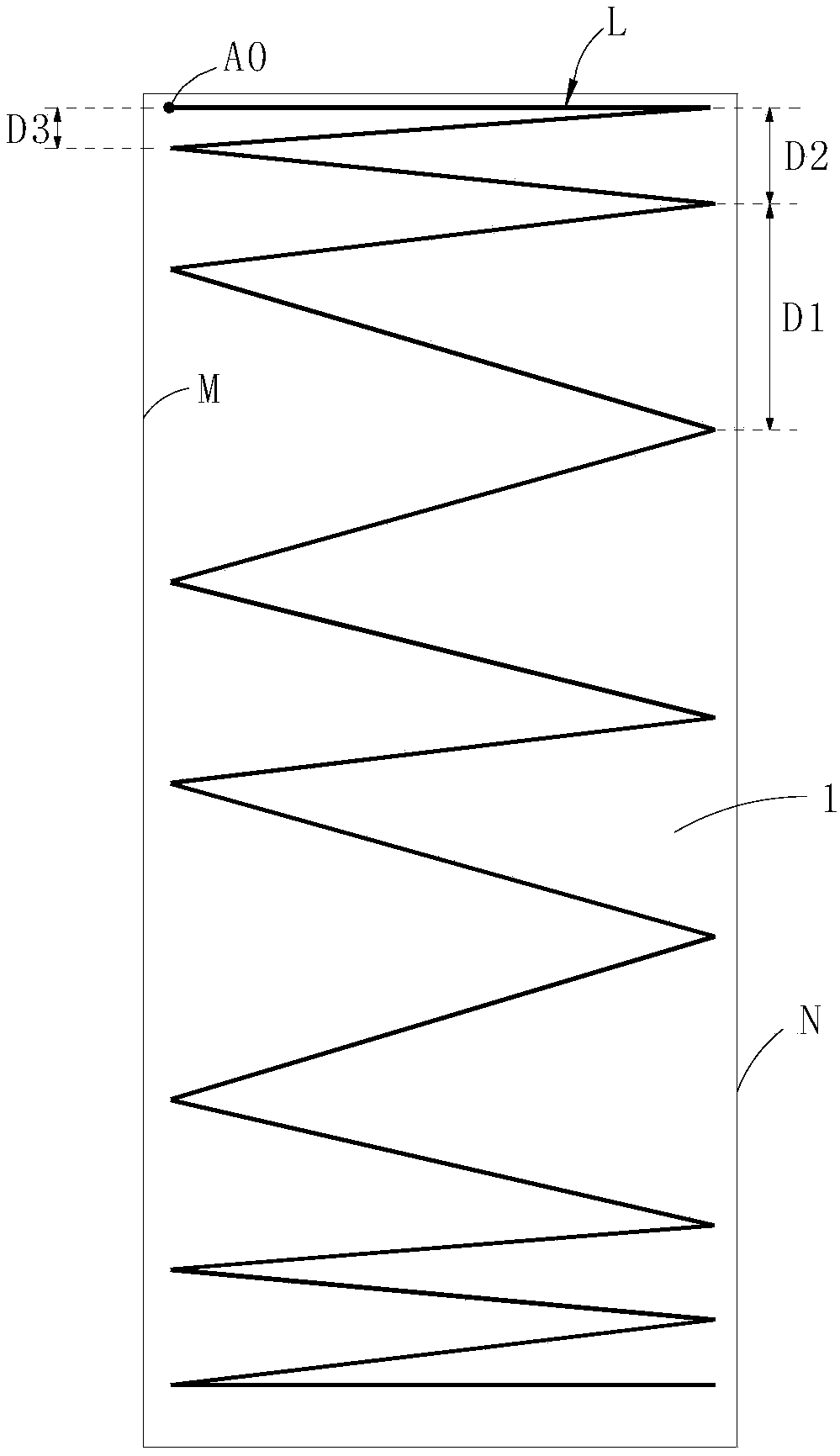

[0030] refer to figure 1 , the dispensing method of the present embodiment mainly comprises the following steps:

[0031] S01. Provide a substrate 1 to be dispensed, and the substrate 1 includes a first side line M and a second side line N oppositely arranged.

[0032] Wherein, the dispensing starting point A0 is close to the first side line M, for example, the first side line M and the second side line N are respectively located on both sides of the width direction of the substrate 1 and extend along the length direction of the substrate 1 . The substrate here can be a crystal holder or an adhesive board.

[0033] S02 , sequentially coating a plurality of dispensing segments L on the substrate 1 to form a dispensing pattern L0 until the starting point and the ending point of the dispensing pattern L0 are separated by a predetermined distance in the length direction of the first side line M.

[0034] In the dispensing pattern L0, the starting point of each dispensing segmen...

Embodiment 2

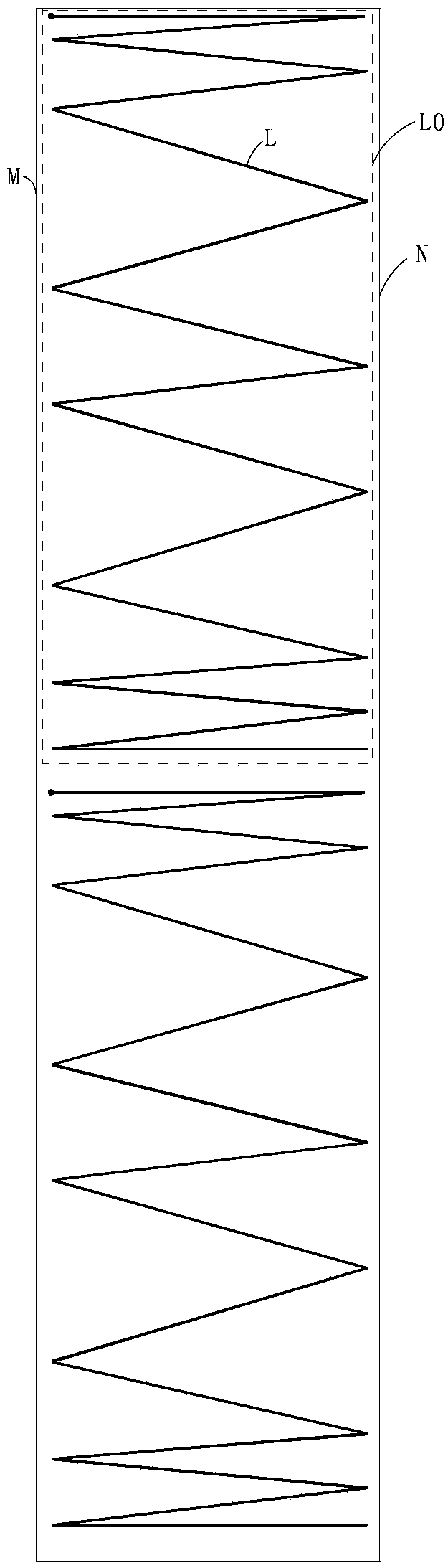

[0042] Such as figure 2 As shown, different from Embodiment 1, there are two dispensing patterns L0 on the substrate of this embodiment,

[0043] The length of each dispensing pattern L0 (the dimension along the length direction of the first side line M) matches the length of two short silicon rods, the length of a single short silicon rod is about 345mm, and the two short silicon rods pass through respectively A dispensing pattern L0 is spliced on the substrate 1 to form a combined silicon rod with a length of about 690mm. Therefore, the length of each dispensing pattern L0 should not be greater than but close to 345mm, that is, the predetermined distance should not be greater than but close to 345mm.

[0044] On the basis of embodiment 1, the dispensing method for silicon wafer production of the present embodiment needs to repeatedly make the next dispensing pattern L0, and also includes the following steps:

[0045] S03. Select a new point near the start point or end po...

Embodiment 3

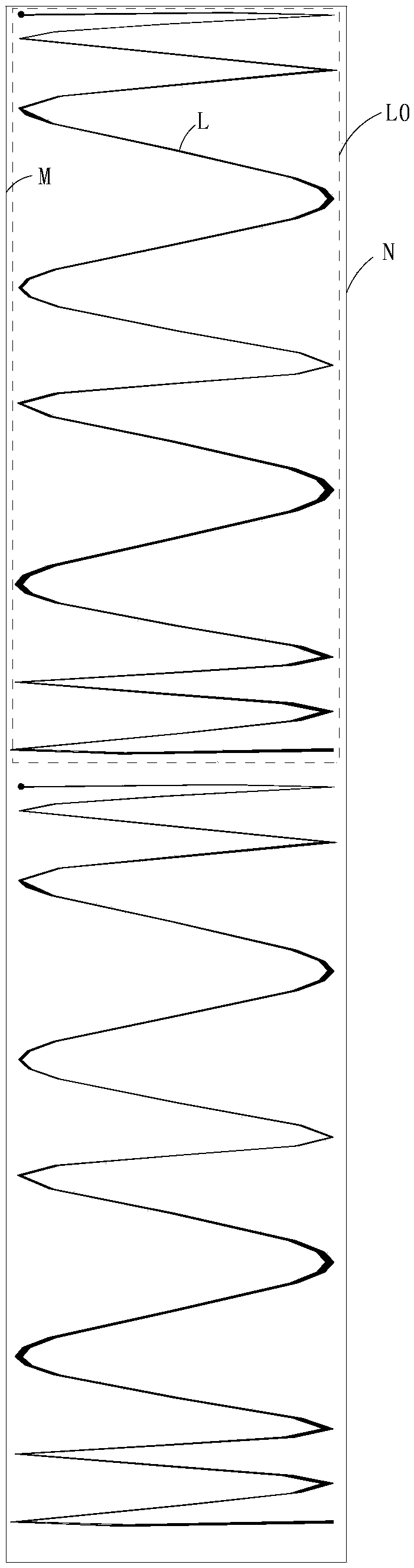

[0051] Such as image 3 As shown, different from the above embodiments, at least one dispensing segment L of this embodiment can be arranged in an arc, and even preferably each dispensing segment L can be an arc. Finally, each dispensing pattern L0 is Squiggly. The connection transition between the dispensing sections L is also an arc transition, which can increase the distance between the two dispensing sections and better prevent glue overflow.

[0052] In summary, the present invention forms a dispensing pattern formed by end-to-end connection of several dispensing sections by dispensing glue on various substrates, such as bonding boards or crystal holders, according to a predetermined track, and the glue line layer after lamination can maintain Very good uniformity, not only can avoid glue overflow, but also can easily discharge the air between the dispensing sections, there will be no empty glue or glue layer bubbles, and it can eliminate the edge of the silicon wafer ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com