Anode hole sealing plug and sealing method thereof

An anode sealing and plugging technology, which is used in the sealing of engines, assembling machines, engine components, etc., can solve the problems of easy falling off of silicone plugs, generation of waste products, loss of processing accuracy of blind holes, etc., and achieves good sealing performance and reliable pressure. The effect of tight force and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better illustrate the implementation details of the present invention, the technical solutions of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

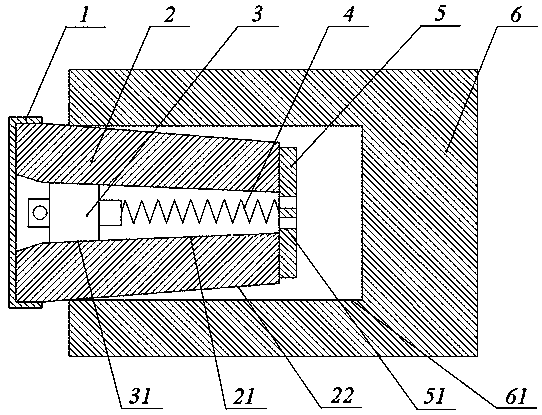

[0021] An anode sealing plug, such as figure 1 As shown, it includes a lifting cover 1, a plug 2, an inner plug 3, a spring 4 and a stopper 5. The material of the plug 2 is silica gel; the material of the inner plug 3 is aluminum alloy; the cover 1 covers the left end of the plug 2; the sealing surface 22 of the plug 2 is a conical surface, and the taper of the sealing surface 22 is 1:6. There is a conical hole 21 inside the head 2, and the taper of the conical hole 21 is 1:9; the conical surface 31 of the inner plug 3 matches the conical hole 21 of the plug 2, and the taper of the conical surface 31 is 1:9; the inner plug 3 The right end of the right end is connected with the block 5 through the spring 4, and there is a pre-tightening te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com