A kind of degradable and strong water absorption double slow-release water-retaining fertilizer and preparation method thereof

A slow-release and fertilizer technology, applied in the field of double slow-release water-retaining fertilizer and its preparation, can solve the problems of refractory degradation, complicated preparation process, and no agricultural promotion, etc., and achieve the effect of good salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

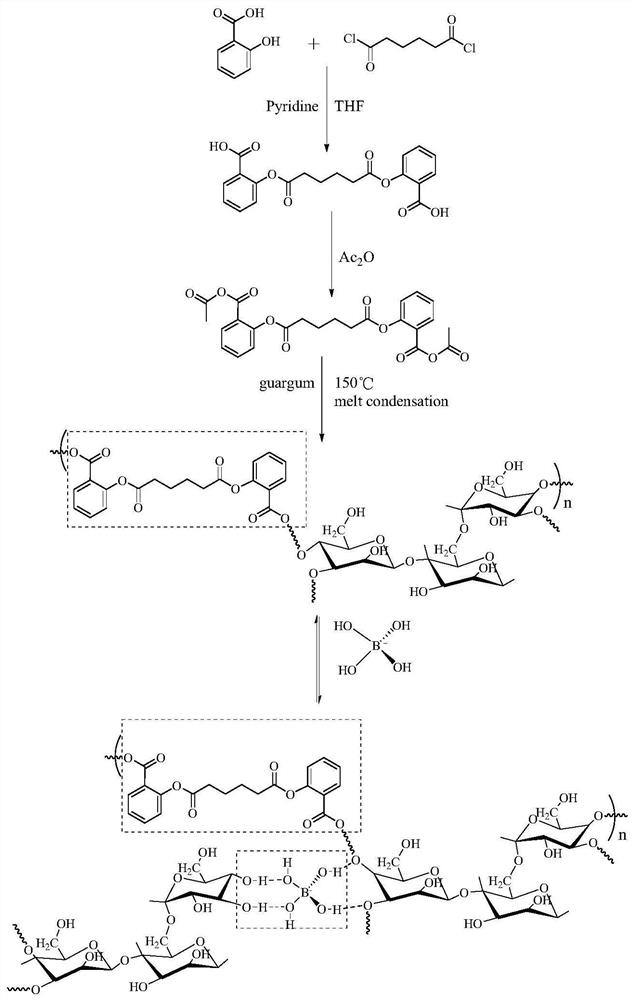

[0029] Concrete preparation process realizes by following reaction:

[0030]

[0031] Specifically, such as figure 1 and figure 2 Shown, the preparation method of a kind of degradable strong water-absorbing double slow-release water-retaining fertilizer of the present invention comprises the following steps:

[0032] (1) Salicylic acid and solvent are dissolved in the three-necked flask, and adipoyl chloride and acid-binding agent are added to the flask by using a constant pressure dropping funnel, wherein the solvent is tetrahydrofuran, and the mass ratio of salicylic acid and tetrahydrofuran is 1:1, the molar ratio of salicylic acid to adipoyl chloride is 2:1, the acid binding agent is pyridine, the molar ratio of pyridine to adipoyl chloride is (2~4):1, and the expansion is carried out at 140~160°C Chain reaction, react for 1 to 2 hours, after the reaction is completed, distill under reduced pressure and dry in vacuo to obtain intermediate I.

[0033] (2) Mix interme...

Embodiment 1

[0039] Dissolve 0.1mol salicylic acid and 13.8g tetrahydrofuran in a three-necked flask, add 0.05mol adipoyl chloride and 0.1mol pyridine using a constant pressure dropping funnel, and react at 160°C for 1 hour under the protection of nitrogen, distill under reduced pressure, vacuum Drying yields Intermediate I. Take intermediate I and acetic anhydride with a molar ratio of 1:2.3, add 0.5wt% concentrated sulfuric acid as a catalyst, heat and reflux at 110°C for 4 hours, cool and crystallize after the reaction is completed, extract, wash with cold water, and recrystallize to obtain intermediate II . Subsequently, the intermediate II and guar gum were reacted at 150°C for 6 hours at a mass ratio of 1:10 for melt polycondensation to obtain the product. The product is formulated into a solution with a concentration of 0.3wt%, and then cross-linked with 2wt% borax solution at a volume ratio of 100:1 to form a gel, freeze-dried and pulverized to obtain a degradable strong water-abs...

Embodiment 2

[0041] Dissolve 0.1mol salicylic acid and 13.8g tetrahydrofuran in a three-necked flask, add 0.05mol adipoyl chloride and 0.15mol pyridine using a constant pressure dropping funnel, and react at 150°C for 1 hour under the protection of nitrogen, distill under reduced pressure, vacuum Drying yields Intermediate I. Take intermediate I and acetic anhydride with a molar ratio of 1:2.4, add 0.5wt% concentrated sulfuric acid as a catalyst, heat and reflux at 105°C for 5 hours, cool and crystallize after the reaction is completed, extract, wash with cold water, and recrystallize to obtain intermediate II . Subsequently, the intermediate II and guar gum were reacted at 150°C for 6 hours at a mass ratio of 1:10 for melt polycondensation to obtain the product. The product is formulated into a solution with a concentration of 0.3wt%, and then cross-linked with 2wt% borax solution at a volume ratio of 100:1 to form a gel, freeze-dried and pulverized to obtain a degradable strong water-ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com