Single-layer PVDF battery diaphragm and preparation method thereof

A battery separator and single-layer technology, applied in the field of single-layer PVDF battery separator and its preparation, can solve the problems of inability to meet the battery process requirements, increase in thickness, etc. The effect of diaphragm interface stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method for a single-layer PVDF battery diaphragm, comprising the following steps:

[0024] S1. Preparation of PVDF coating: Weigh the amount of polyvinylidene fluoride W#8500, polyvinylidene fluoride-hexafluoropropylene copolymer and acetone into the stirring reactor, and heat it with water at 30°C-80°C After one hour until it is completely melted, after stirring for one hour at room temperature in a stirring reactor, add a certain amount of n-propanol, dimethyl carbonate, and cyclohexane, and stir for one hour to obtain a single-layer PVDF coating product;

[0025] S2. Coating: Put the PVDF coating obtained in step S1 into the glue tank of the coater through the pipeline, and coat the upper end of the base film at a coating speed of 5-15m / min. During the process of the coater, use an appropriate amount of Air volume, wind speed for drying.

[0026] Preferably, in step S1, the rotating speed of the stirred reactor is 50-80r / min.

[0027] Preferably, in s...

Embodiment 1

[0029] PVDF coating is prepared from the following raw materials by mass: polyvinylidene fluoride W#85000.5-3.0Kg, polyvinylidene fluoride-hexafluoropropylene copolymer 3Kg, acetone 200Kg, n-propanol 7.5Kg, dimethyl carbonate 6Kg, cyclohexane 1Kg, isopropanol 0.5Kg.

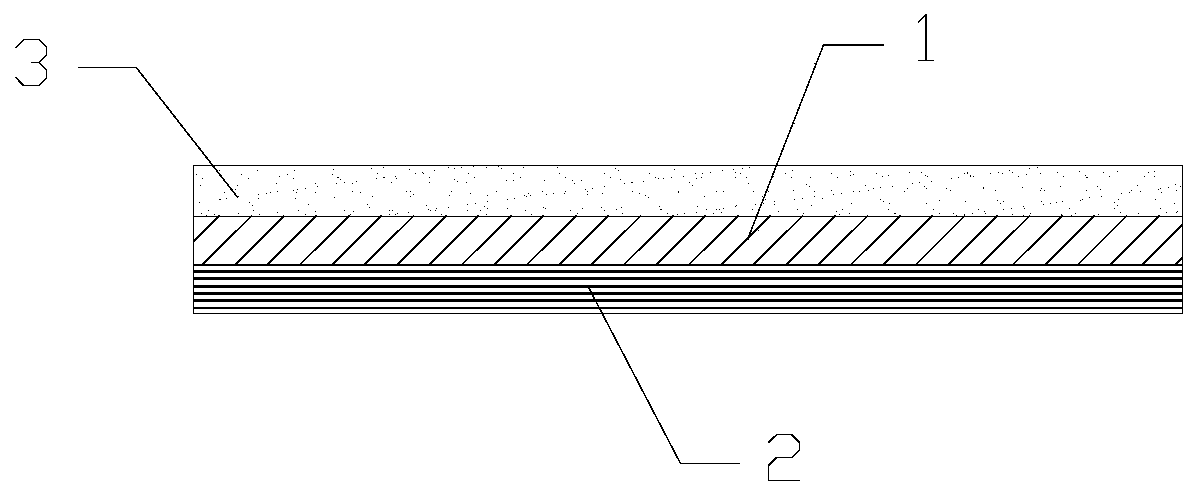

[0030] Further, the thickness of the ceramic layer 2 is 0.5 mm; the thickness of the PVDF coating layer 3 is 0.5 mm.

Embodiment 2

[0032] PVDF coatings are prepared from the following raw materials by mass: polyvinylidene fluoride W#8500 1.5Kg, polyvinylidene fluoride-hexafluoropropylene copolymer 5Kg, acetone 300Kg, n-propanol 11Kg, dimethyl carbonate 11Kg, Cyclohexane 5Kg, isopropanol 1.5Kg.

[0033] Further, the thickness of the ceramic layer 2 is 5 mm; the thickness of the PVDF coating layer 3 is 2.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com