Conveying belt tearing detection system and method based on AI intelligent analysis

A technology of intelligent analysis and conveying belts, which is applied in the direction of material analysis, image analysis, and material analysis through optical means, can solve the problems of personnel injury economy, equipment damage, intrusion, etc., to reduce accident losses, improve work efficiency, and speed up speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

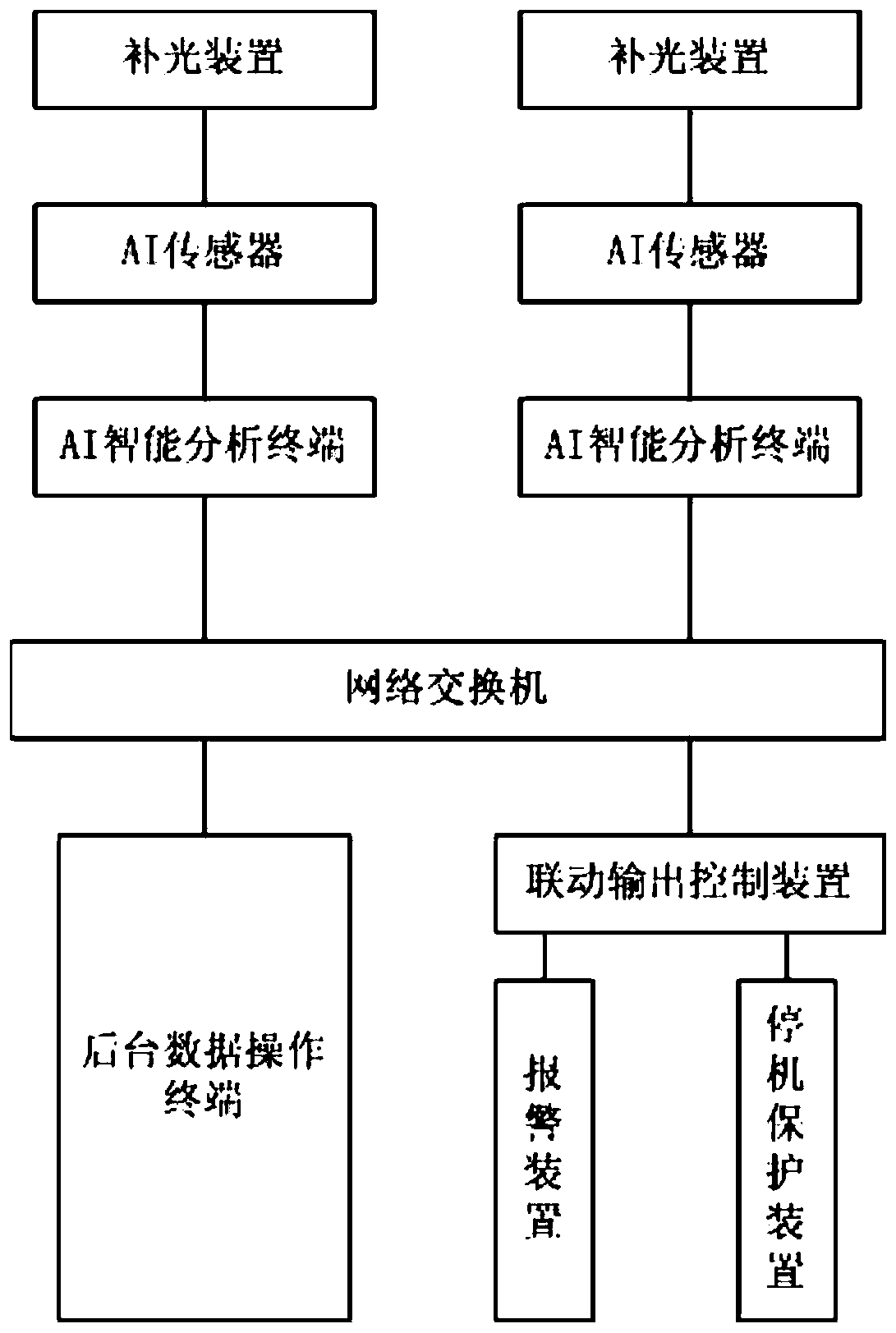

[0028] A conveyor belt tear detection system based on AI intelligent analysis, such as figure 1 , is characterized in that it includes a supplementary light, an AI sensor, an AI intelligent analysis terminal, a network switch, a background data operation terminal, a linkage output control device, an alarm device, and a shutdown protection device. There are two analysis terminals, which are respectively distributed on the left and right sides of the conveyor belt and run side by side. The AI intelligent analysis terminal and the linkage output control device are connected to the network using optical fiber or WIFI, and communicate with the background data operation terminal through the network, and the linkage output control device is connected to the alarm. Equipment and downtime protection devices, AI intelligent analysis terminals and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com