Preparation method of fluorinated modified fluorescent dissolved oxygen sensing film and coating for preparing protective layer

A technology of dissolved oxygen and sensing film, applied in chemical instruments and methods, luminescent materials, fluorescence/phosphorescence, etc., can solve the problems of fragile protective layer, long response time, poor long-term stability, etc., to improve hydrophobicity, enhance affinity and the effect of excellent ability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

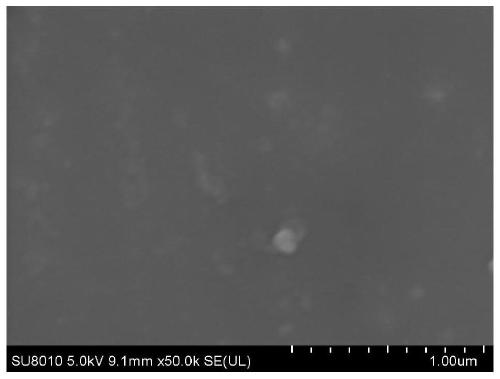

[0050] Preparation of fluorinated organically modified fluorescent dissolved oxygen sensing membrane, the specific steps are as follows:

[0051] Add 1.24ml trimethoxy (3,3,3-trifluoropropyl) silane and 1.36ml tetraethyl silicate into the transparent screw bottle, then continue to add 0.48ml deionized water and 2.50ml absolute ethanol, and then add 0.1mol / L hydrochloric acid is used as a catalyst, and the pH is adjusted to 1.3. Cover and seal with magnetic stirring for 1.2 hours, add 1.0ml tris(4,7-biphenyl-1,10-phenanthroline) ruthenium dichloride ethanol solution, the indicator concentration is 6mg / mL, and ultrasonically stir for 20 minutes, Put it into a dark environment and age it at room temperature for 24 hours. Finally, 60 microliters of fluorescent sol solution was spin-coated on the surface of the pre-treated transparent substrate by using a homogenizer, and dried naturally to prepare a fluorinated modified dissolved oxygen sensing film.

Embodiment 2

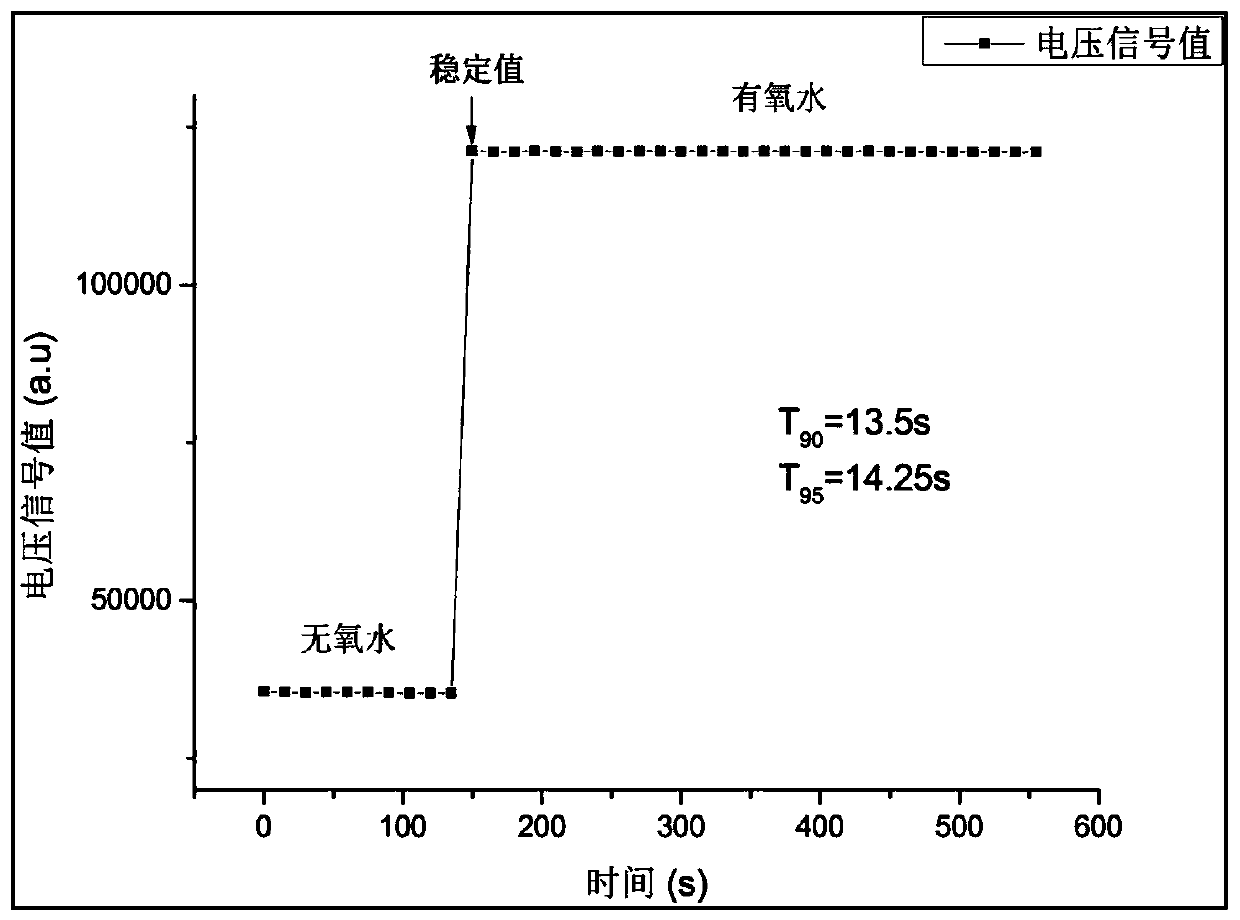

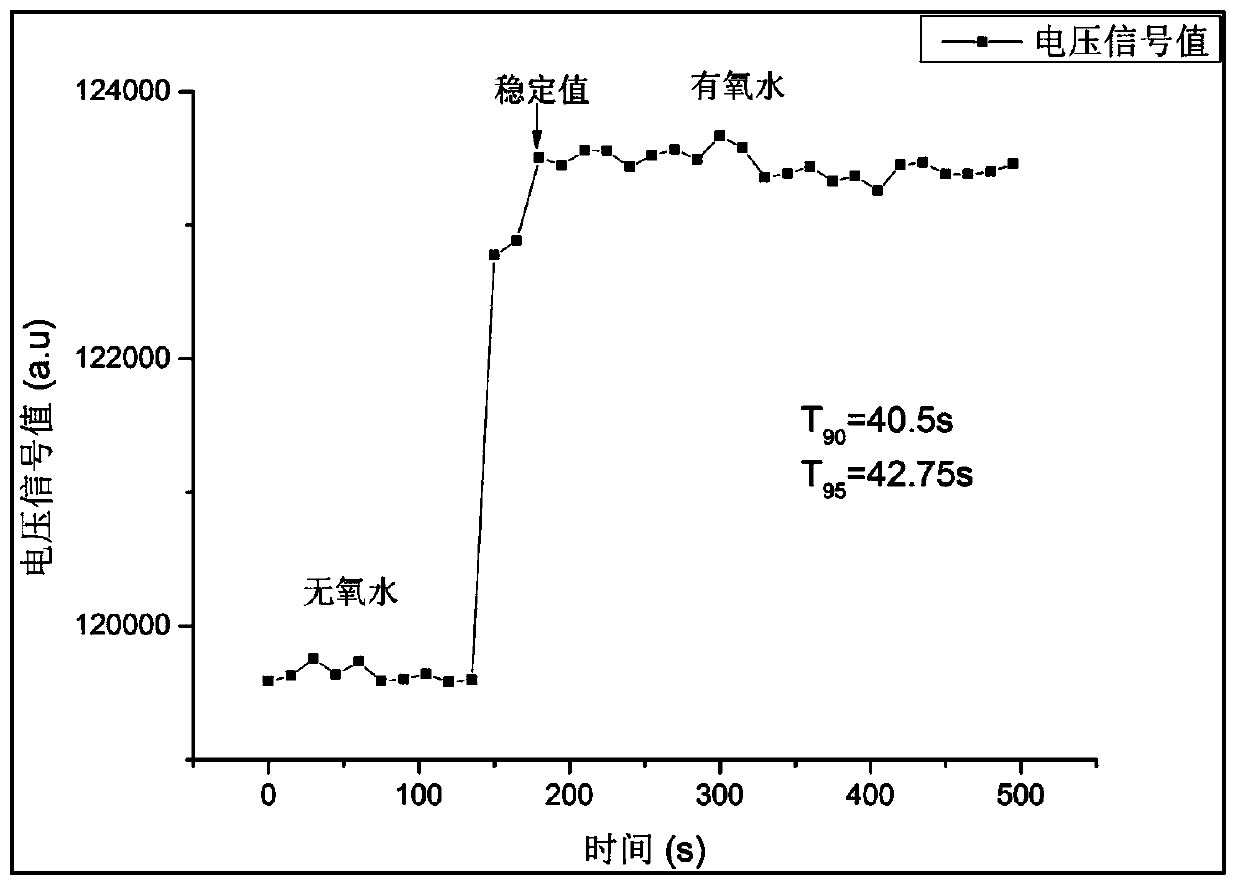

[0053] Embodiment 2-6 refers to the method of embodiment 1, and difference is that the concentration of fluorescent indicator ethanol solution is 3mg / mL (embodiment 2), 12mg / mL (embodiment 3), 18mg / mL (embodiment 4) successively. ), 24mg / mL (embodiment 5), 30mg / mL (embodiment 6), the experimental results show that within a certain range, the increase of the concentration of the fluorescent indicator is conducive to enhancing the oxygen quenching effect and improving the sensitivity of the fluorescent dissolved oxygen sensing film. However, there is also a self-quenching phenomenon between the indicator molecules, and the increase in the concentration of the indicator also strengthens the self-quenching phenomenon, so the sensitivity of the fluorescent film is reduced. Therefore, the concentration of the fluorescent indicator is regulated. The oxygen prepared in Examples 1-6 The sensitivities of the sensing membranes were 2.8, 2.5, 3.3, 3.5, 3.7, and 2.6, respectively. The resul...

Embodiment 7

[0055] Embodiment 7-9 refers to the method of embodiment 5, difference is that the aging time of fluorescent sol solution is successively 48 hours (embodiment 7), 72 hours (embodiment 8), 96 hours (embodiment 9), find Cracks appeared on the surface of the dissolved oxygen film aged for 96 hours. The experimental results showed that the sensitivity of the sensing film gradually increased with the increase of the aging time, but the thickness of the film increased with the aging time, and its internal stress Also bigger, cause the cracking of film, therefore the aging time of sol solution is regulated and controlled, and the result shows that aging time is when 48 hours (embodiment 7), the sensitivity of the fluorescent dissolved oxygen film that obtains is higher, is 3.8, and The surface is smooth and uncracked.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com