Automatic core discharging device for electro-spark wire-electrode cutting peripheral hole slot of tubular part

An EDM line and automatic discharge technology, which is applied in the direction of auxiliary devices, electric processing equipment, metal processing equipment, etc., can solve the problems of increasing the workload of workers, the inability to automate processing, and reducing productivity, so as to shorten the pause time and ensure continuous operation. , the effect of liberating the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

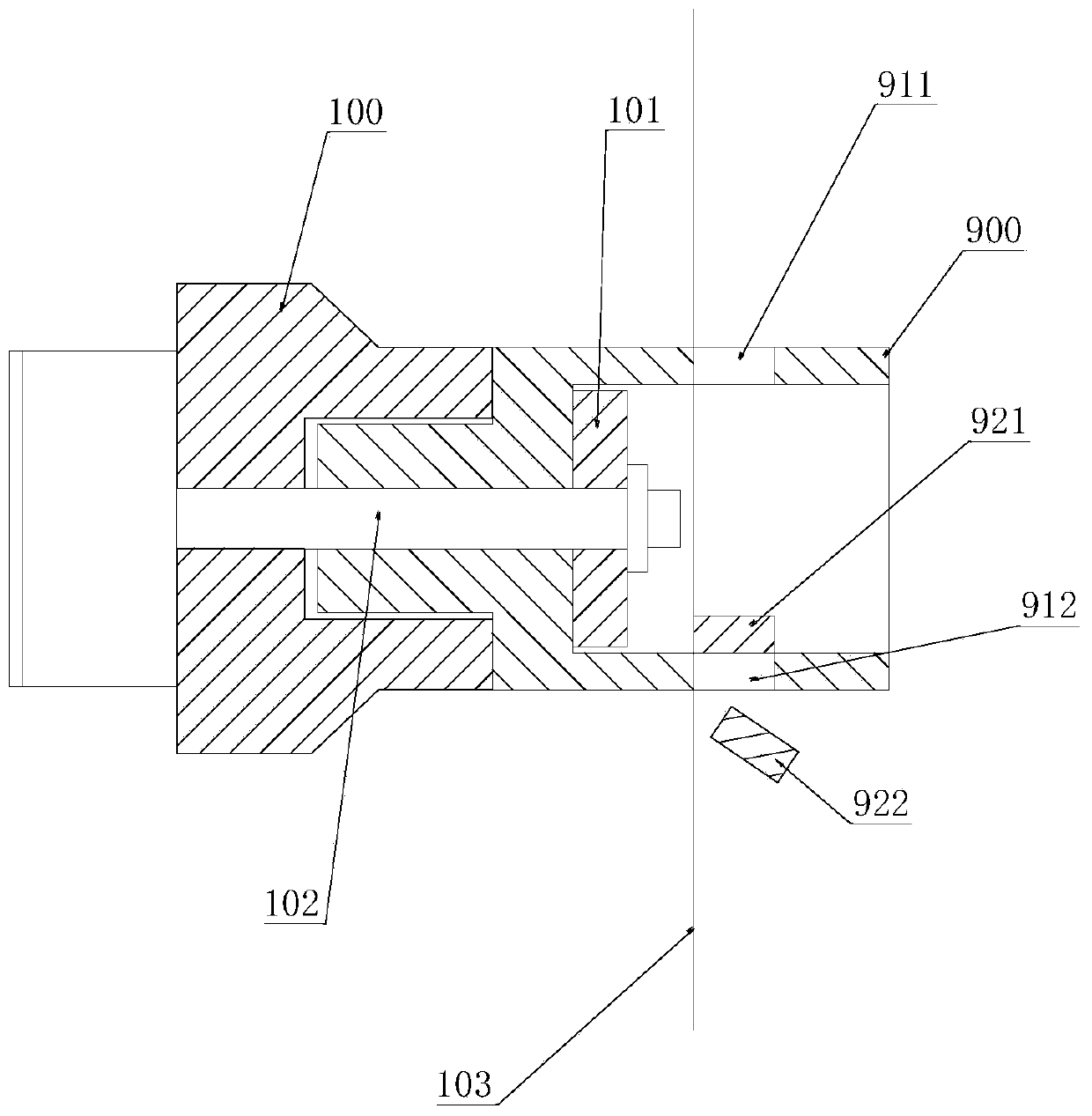

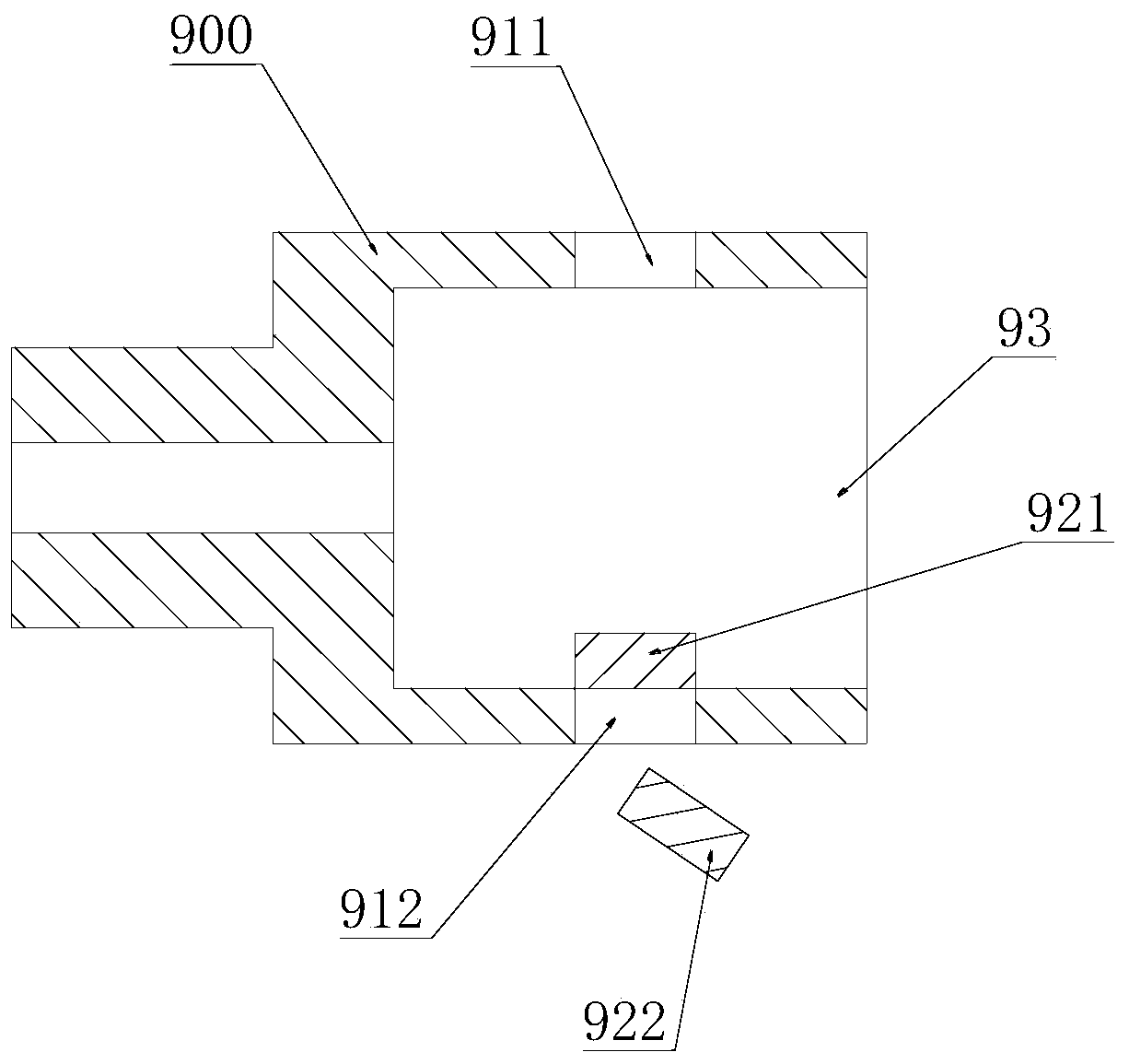

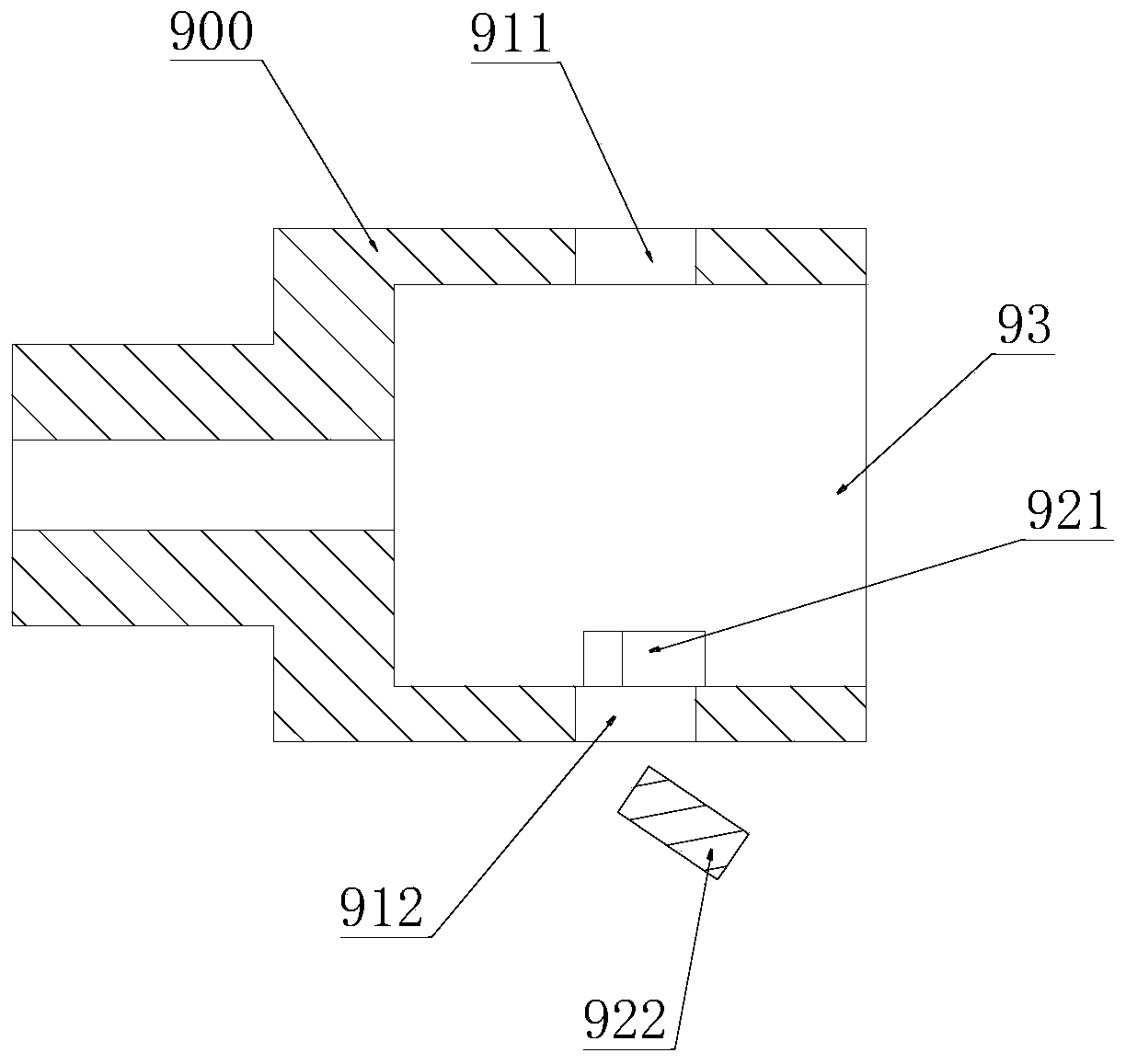

[0041] figure 2 , image 3 It is a schematic diagram showing the falling position of the feeding core 921 of a tubular part 900 in the embodiment of the present invention after one cutting, and the feeding core 921 formed in the upper hole groove 911 above the tubular part 900 will fall to the inside of the tubular part 900 and will stay near the lower hole 912 below, and the lower core 922 formed by the lower hole 912 below will fall to the outside of the tubular part 900. This upper and lower core 921, 922 is a block structure, Figure 4 is a schematic diagram of the deflection of the loading core 921 when it falls or is discharged, because the position of the loading core 921 will be deflected when it falls, so figure 2 , image 3 The drop locations in are for illustration only. It should be noted that the structure of the tubular part 900 in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com