Electromagnetic device and method for orderly deposition of wear particles

A technology of wear particles and electromagnetic devices, applied in particle and sedimentation analysis, measuring devices, chemical instruments and methods, etc., can solve the problems of inability to achieve orderly deposition of wear particles, increase the volume and complexity of the device, and avoid deposition Regular destruction, avoiding temperature rise, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

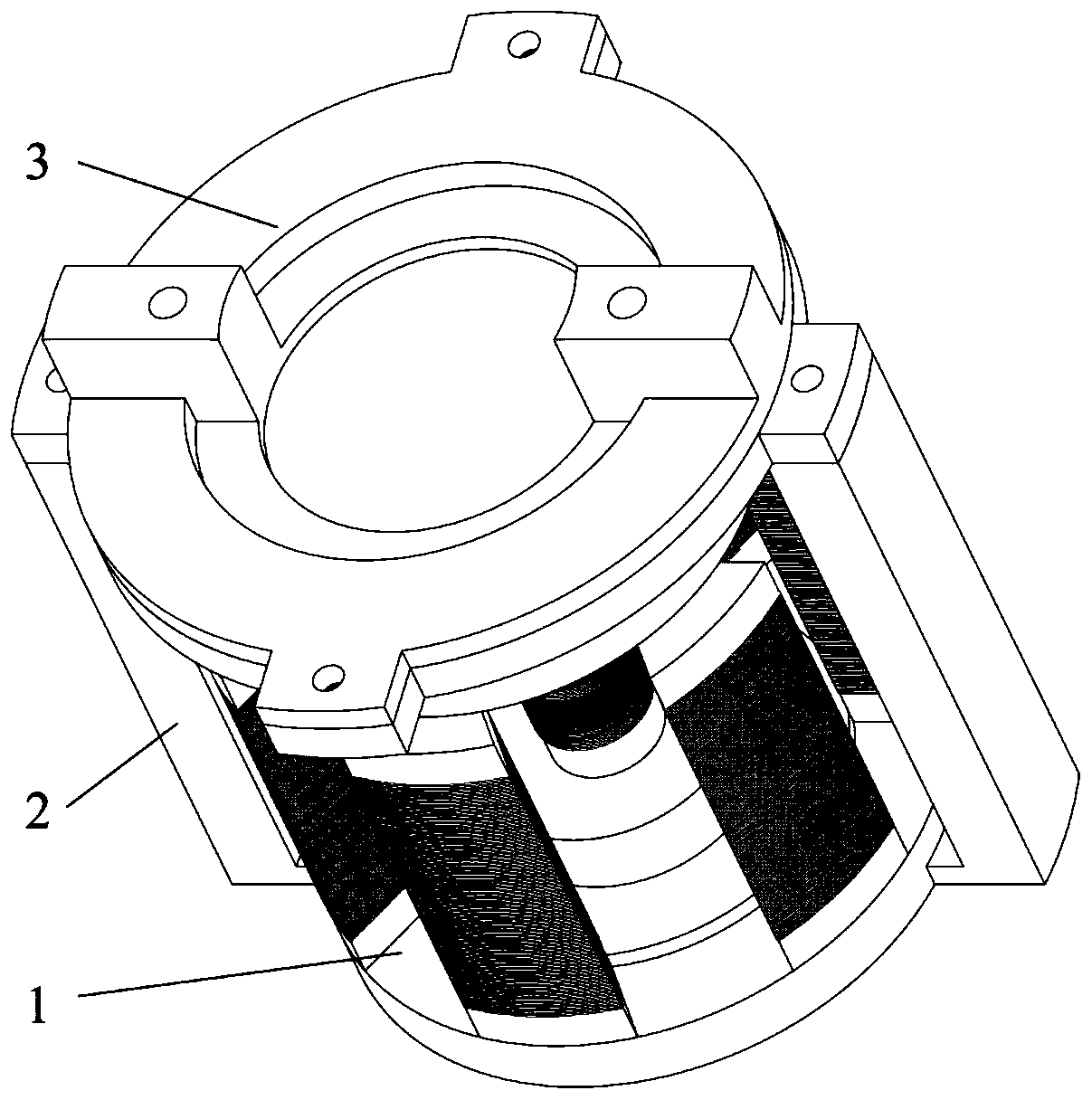

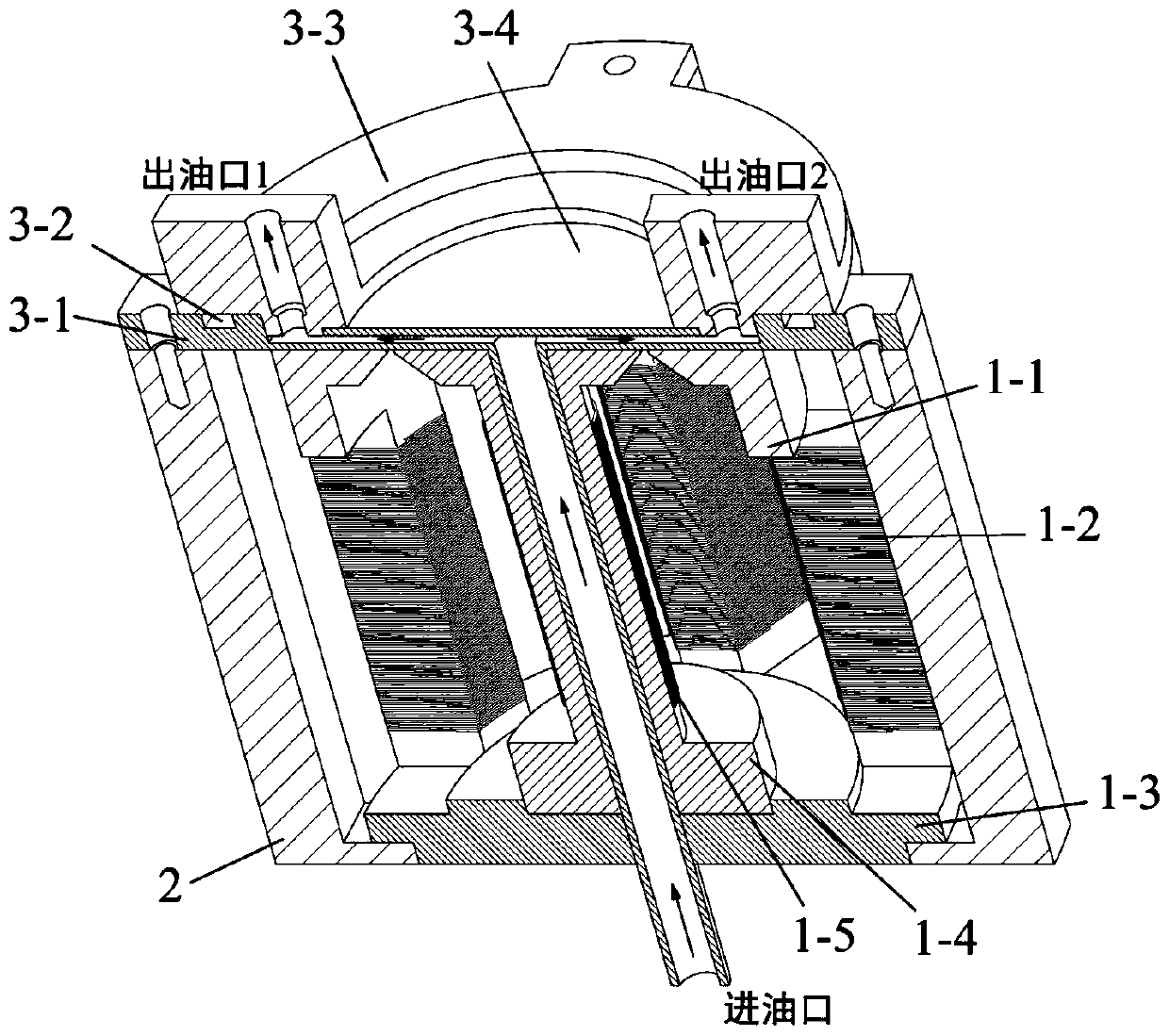

[0035] Embodiment 1 of the present disclosure discloses an electromagnetic device for orderly deposition of wear particles, which mainly includes:

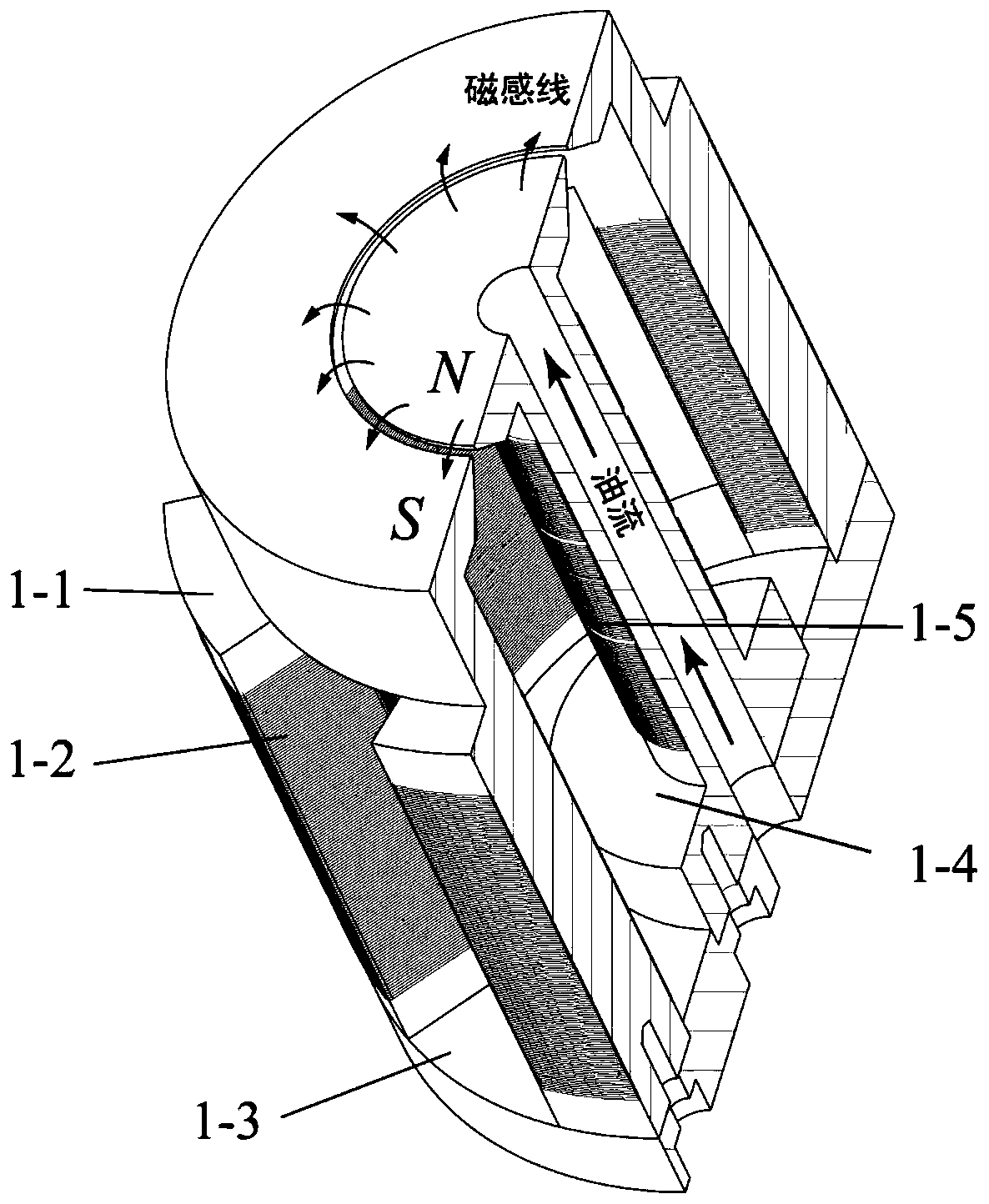

[0036] Inner electromagnet—at least two sets of enamelled copper wires are wound on the inner electromagnet column, and the magnetic induction intensity is controlled by controlling the on and off of the current in the coil. There is a through hole in the center of the magnet for the placement of the flow channel;

[0037] Outer electromagnet—the outer electromagnet includes at least two sets of columns and the number of sets is the same as that of the inner electromagnet copper wires. The columns are wound with enamelled copper wires, and the magnetic induction intensity is controlled by controlling the on-off of the current in each set of coils;

[0038] Yoke—connects the magnetic circuit and transmits the magnetic field lines.

[0039] Flow Passages - The lubricating oil flows through the deposit areas through flow passages.

...

Embodiment 2

[0051] Embodiments of the present disclosure also disclose a deposition method of an electromagnetic device for orderly deposition of wear particles, which mainly includes the following steps:

[0052] The intensity of the annular deposition magnetic field generated by the electromagnet 1 is adjusted by controlling the number of energized coils. When the device is in operation, firstly, the columns opposite to the outer electromagnet form a group, and the same current of a certain intensity is passed to a group of outer electromagnet coils and a group of inner electromagnet coils, and a group of outer electromagnet coils 1-2 and a group of The inner electromagnet coil 1-3 is fed with the same current of a certain intensity, and the electromagnet 1 will generate a high-gradient magnetic field of a certain intensity between the lower part 3-1 of the flow channel and the upper part 3-3 of the flow channel, and the magnetic field will make the Ferromagnetic particles with a size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com