Preparation method and application of adsorption and degradation material

A technology for adsorbing degradation and degrading liquid, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve problems such as secondary environmental pollution, and achieve the effects of environmental friendliness, wide source of raw materials, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

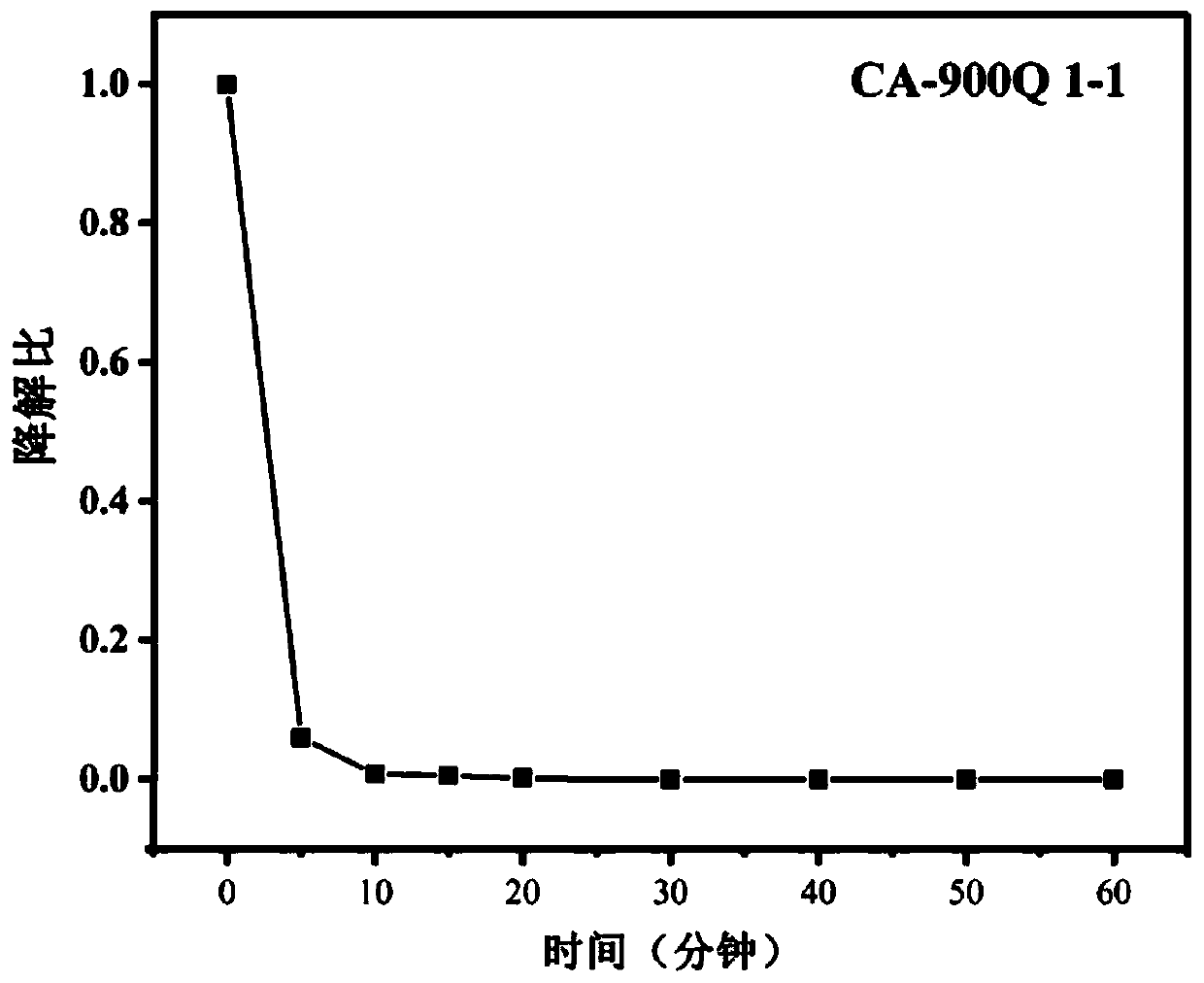

Image

Examples

preparation example Construction

[0036] The preparation method of a kind of adsorption degradation material provided by the present invention and the preparation method of application thereof, specifically comprise the following steps:

[0037] Step a, adding glacial acetic acid into the chitosan solution, stirring constantly during the adding process, and obtaining a uniform and stable hydrogel after standing for a period of time. Wherein, the concentration of the chitosan solution is 2.5g / L-40g / L, and the ratio of glacial acetic acid to chitosan is 0.4ml / g-1.6ml / g. During the addition of glacial acetic acid, constant stirring is required to ensure that chitosan and glacial acetic acid react completely. After the addition, it must be allowed to stand long enough to age until the formed hydrogel is uniform and stable, at least one hour is required.

[0038] In step b, the static hydrogel is slowly dropped into liquid nitrogen for rapid freezing to obtain a frozen product. Among them, the static hydrogel is ...

Embodiment 1

[0050] Step a, dissolve 1g of chitosan in 100ml of aqueous solution, fully stir until dispersed to obtain a chitosan solution with a concentration of 10g / L, add 0.4ml of glacial acetic acid to this solution, and keep stirring evenly during the addition process to A viscous hydrogel was obtained, and then aged for 1.5 hours to obtain a uniform and stable hydrogel.

[0051] In step b, absorb the hydrogel prepared in step a with a rubber dropper and slowly drop it into liquid nitrogen at a rate of 1 drop / s for rapid freezing to obtain a frozen product.

[0052] In step c, the frozen product obtained in step b is put into a freeze dryer and freeze-dried at -50° C. for 1 day to obtain an aerogel.

[0053] In step d, the obtained airgel is calcined at 800° C. under a nitrogen or argon atmosphere at a heating rate of 3° C. to obtain a first calcined product.

[0054] In step e, the obtained first calcined product was mixed with 20ml of water at a mass ratio of first calcined product...

Embodiment 2

[0058] Step a, dissolve 4g of chitosan in 400ml of aqueous solution, fully stir until dispersed to obtain a chitosan solution with a concentration of 10g / L, add 1.6ml of glacial acetic acid to this solution, and stir continuously during the addition process to A viscous hydrogel was obtained, and then aged for 2 hours to obtain a uniform and stable hydrogel.

[0059] In step b, absorb the hydrogel prepared in step a with a rubber dropper and slowly drop it into liquid nitrogen at a rate of 1 drop / s for rapid freezing to obtain a frozen product.

[0060] In step c, the frozen product obtained in step b is put into a freeze dryer and freeze-dried at -50° C. for 1 day to obtain an aerogel.

[0061] In step d, the obtained airgel is calcined at 800° C. under a nitrogen or argon atmosphere at a heating rate of 3° C. to obtain a first calcined product.

[0062] In step e, the obtained first calcined product was mixed with 40ml of water at a mass ratio of first calcined product:KOH=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com