Automatic slicing machine for fish processing

A slicer and fish technology, applied in fish processing, metal processing, application, etc., can solve the problems of inconvenient use and inability to adjust the thickness of fish fillets, and achieve the effects of quick response, infinitely variable speed adjustment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

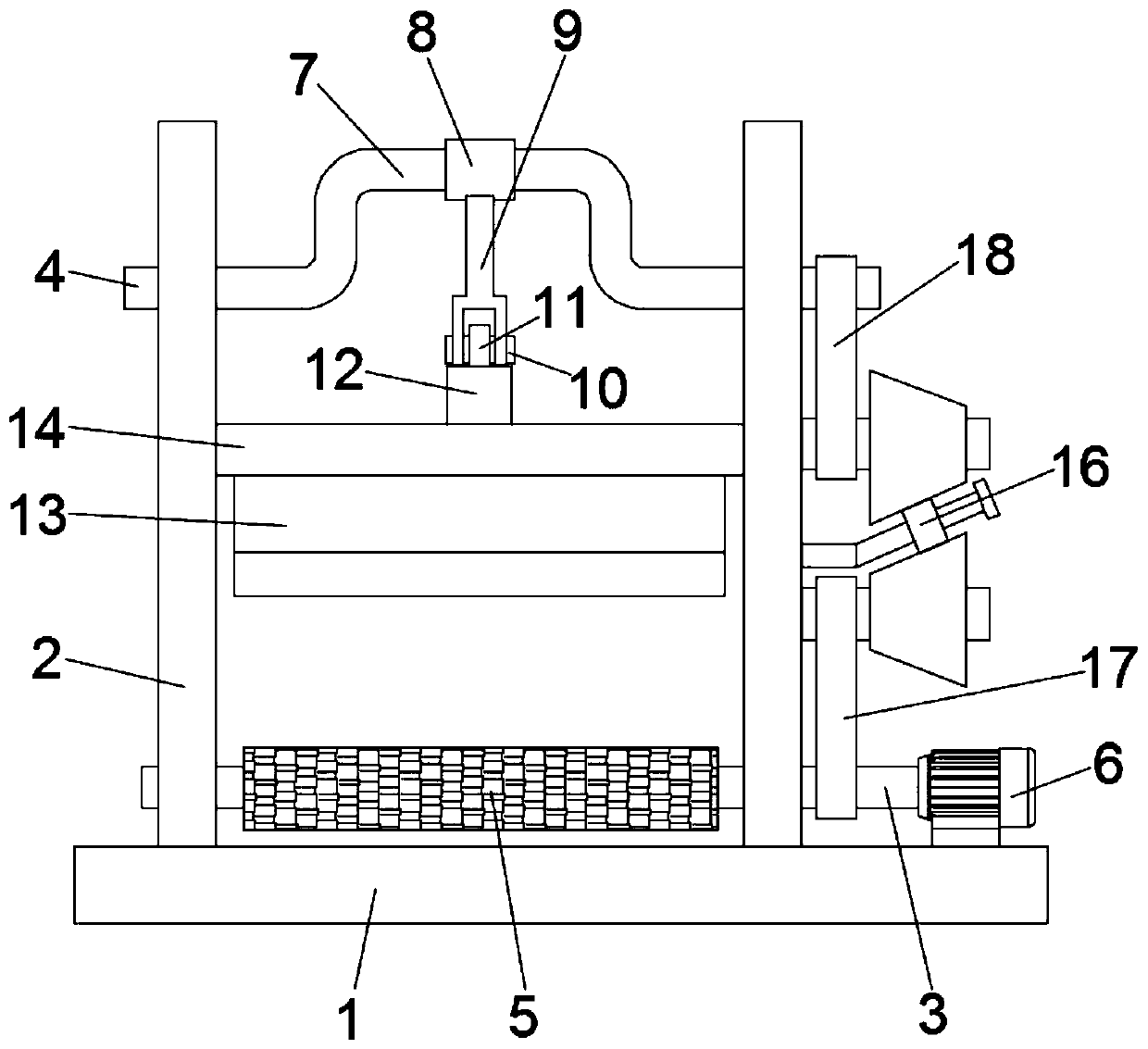

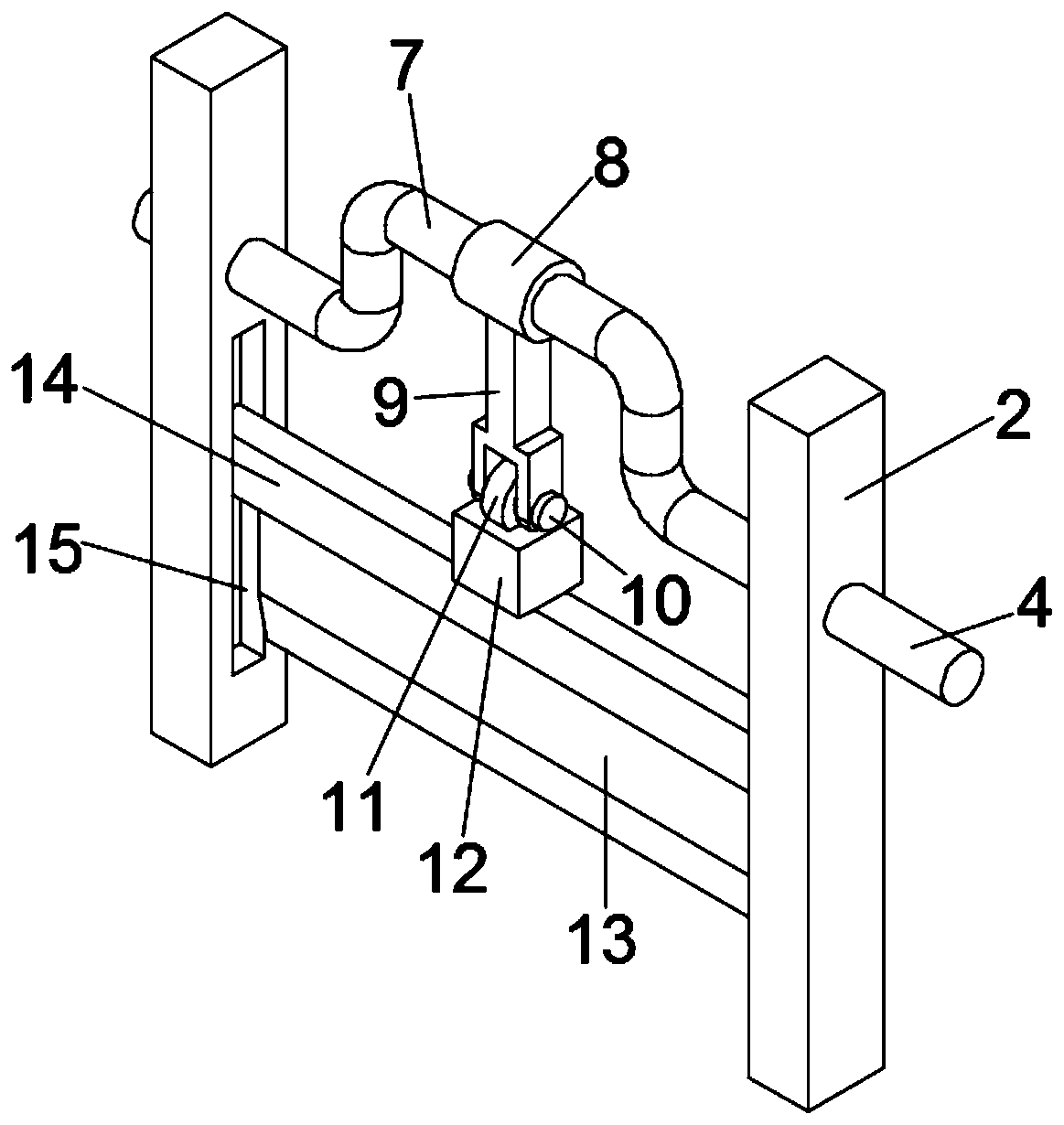

[0022] see figure 1 , an automatic slicer for fish processing, comprising a workbench 1, support plates 2 are vertically installed on both sides of the workbench 1, and a transmission shaft 3 is installed between the support plates 2 on both sides, and the transmission shaft 3 One end is connected with a motor 6 fixed on the workbench 1, and a conveyor belt 5 for transporting fish is installed on the transmission shaft 3; the support plates 2 on both sides are vertically provided with chutes 15, and the slides in the chutes 15 Embedded with a slider 14, a cutter 13 is installed on the bottom of the slider 14, and a reciprocating drive mechanism that drives the cutter 13 to reciprocate up and down is also installed on the support plate 2; on the side wall of the support plate 2 close to the motor 6 A speed regulating assembly 16 is installed;

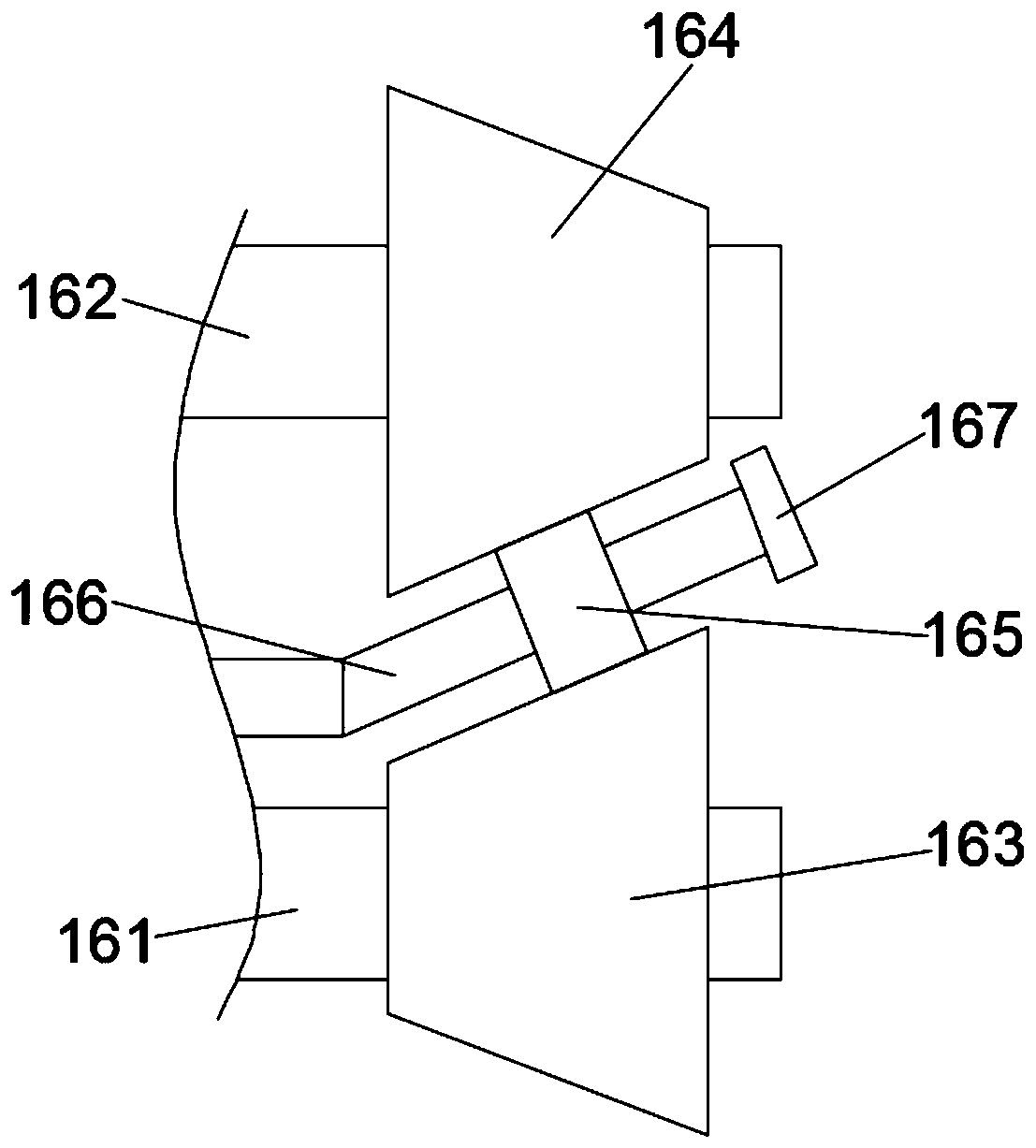

[0023] see figure 2 The speed regulating assembly 16 includes a first rotating shaft 161, a second rotating shaft 162, an adjusting ...

Embodiment 2

[0032] In order to improve the effectiveness of the transmission of the speed regulating assembly 16, this embodiment has been further improved on the basis of Embodiment 1. The improvement is: the outside of the first turntable 163, the second turntable 164 and the adjustment wheel 165 are all coated with Anti-slip coating, increase transmission friction through anti-slip coating, avoid slipping, cause transmission failure, and improve stability;

[0033] The specific material of the anti-slip coating is not limited. In this embodiment, preferably, the anti-slip coating is made of polyurethane.

[0034] The automatic slicer for fish processing realizes the adjustment of the rotating speed of the crankshaft 4 through the speed regulating assembly 16, thereby changing the frequency of the reciprocating movement of the cutting knife 13 up and down. Since the speed of the conveyor belt 5 is constant, the thickness of the fish fillets can be changed, and only need to be moved The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com