A conductive silver paste for electrodes in low dielectric constant LTCC ceramics

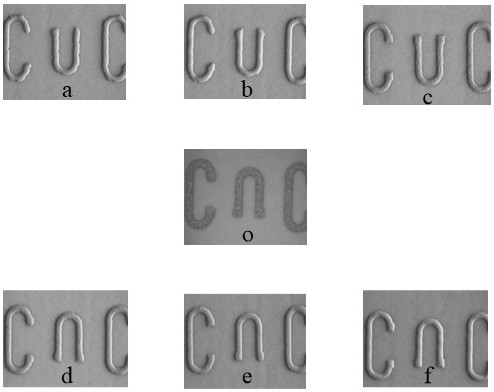

A low dielectric constant, conductive silver paste technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of lack of porcelain powder and electrode paste, hindering industrial upgrading and progress, etc., and achieve excellent flow performance , Excellent printing process performance, high flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of the conductive silver paste that is used for the inner electrode of low dielectric constant LTCC porcelain mainly comprises the following steps:

[0027] 1. First, mix the polymer resin with the solvent in proportion, and heat until completely dissolved to make an organic carrier; use ethyl cellulose (Dow Chemical), which is commonly used for making silver paste, as the polymer resin; use silver paste as a general-purpose solvent for making Butyl carbitol acetate is mixed with terpineol 1:1 (Dow Chemical);

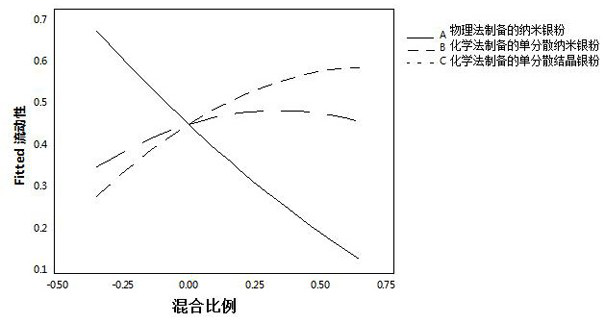

[0028] 2. Fully mix the organic carrier, silver powder, and additives in the mixer; for the mixed silver powder system, the additives further promote the uniform mixing of different silver powders through the principle of surface throttling and same-sex charge repulsion, and at the same time prevent the agglomeration of nano-silver powder;

[0029] 3. Fully disperse the mixture on a three-roll mill to obtain a uniform conductive silve...

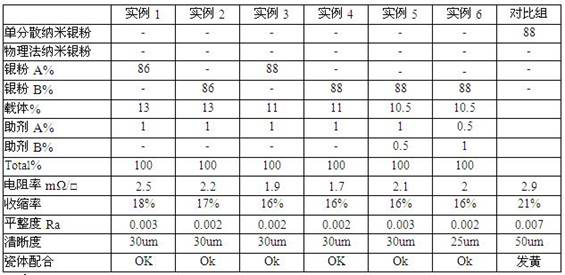

Embodiment 1

[0033]A kind of conductive silver paste for low dielectric constant LTCC porcelain inner electrode, as shown in table 1, comprises 86% silver powder A, 13% carrier, 1% auxiliary agent A, and described silver powder A is prepared by the nanometer The silver powder and the monodisperse crystalline silver powder prepared by the chemical method are composed according to the mass ratio of 3:1, and are mixed and prepared by using a V-type powder mixer. The D50 particle diameter of the nano-silver powder is 500nm, and the D50 particle diameter of the monodisperse crystalline silver powder is 2.5um. The auxiliary agent A is prepared by adding 1 part of long-chain fatty acid to 1 part of butyl carbitol, and fully dissolving at 80° C. for 12 hours.

Embodiment 2

[0035] A kind of conductive silver paste for low dielectric constant LTCC porcelain inner electrode, as shown in table 1, comprises 86% silver powder B, 13% carrier, 1% auxiliary agent A, and described silver powder B is prepared by the nanometer of physical method Silver powder, monodisperse crystalline silver powder prepared by chemical method, and monodisperse nano-silver powder prepared by chemical method are composed according to the mass ratio of 30:10:1, and are mixed and prepared by using a V-type powder mixer. The D50 particle diameter of the nano silver powder is 500nm, and the D50 particle diameter of the monodisperse crystalline silver powder is 2.5um, and the D50 particle diameter of the monodisperse nano silver powder is 120nm. The auxiliary agent A is prepared by adding 1 part of long-chain fatty acid to 1 part of butyl carbitol, and fully dissolving at 80° C. for 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com