Cross-linked microsphere as well as preparation method and application thereof

A technology of cross-linking microspheres and microspheres, which is applied in the fields of biochemical equipment and methods, microorganisms, artificial cell structures, etc., can solve the problems of high viscosity, unsatisfactory size, and narrow application range of chitosan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

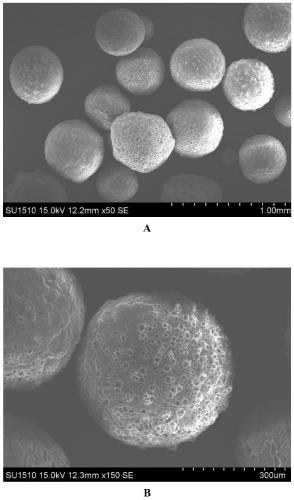

Embodiment 1

[0094] Chitosan powder (1.2g, degree of deacetylation is 98.7%, viscosity is 29mPa.s, purchased from Zhejiang Golden Shell Pharmaceutical Co., Ltd.) was added to 2% (w / v) glacial acetic acid aqueous solution (60mL), Dissolve at 65° C. for 5 h, and let stand for 24 h to obtain a bubble-free, uniform and transparent 2% (w / v) chitosan solution (60 mL).

[0095] Add type A gelatin (2.4g) with 250 freezing strength (double freezing strength) into deionized water (60mL), dissolve at 65°C, and let it stand for 24h to obtain stable and transparent 4% (w / v) gelatin solution (60 mL).

[0096] Mix the chitosan solution and the gelatin solution, and use a 13000rpm high-speed homogenizer to homogenize for 10 minutes to make them mix uniformly to obtain a chitosan-gelatin mixed solution with a solid content of 3.0%.

[0097] The chitosan-gelatin mixed solution was placed in the atomizer of the spray freezing tower, and sprayed into the cooling tower pre-cooled to -60 ° C, the frozen micros...

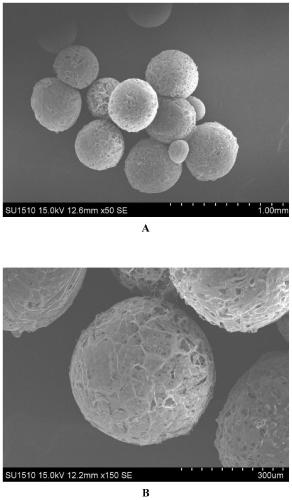

Embodiment 2

[0100] Chitosan powder (2.0g, degree of deacetylation is 90%, viscosity is 112mPa.s, purchased from Zhejiang Golden Shell Pharmaceutical Co., Ltd.) was added to 2% (w / v) glacial acetic acid aqueous solution (100mL), Dissolve at 65° C. for 5 h, and let stand for 24 h to obtain a bubble-free, uniform and transparent 2% (w / v) chitosan solution (100 mL).

[0101] Add type A gelatin (1.0g) with 250 freezing strength (double freezing strength) into deionized water (25mL), dissolve at 65°C, and let stand for 24h to obtain stable, transparent 4% (w / v) gelatin solution (25 mL).

[0102] Mix the chitosan solution and the gelatin solution, and use a 13000rpm high-speed homogenizer to homogenize for 10 minutes to make them mix uniformly to obtain a chitosan-gelatin mixed solution with a solid content of 2.4%.

[0103] The chitosan-gelatin mixed solution was placed in the atomizer of the spray freezing tower, and sprayed into the cooling tower pre-cooled to -60 ° C, the frozen microsphere...

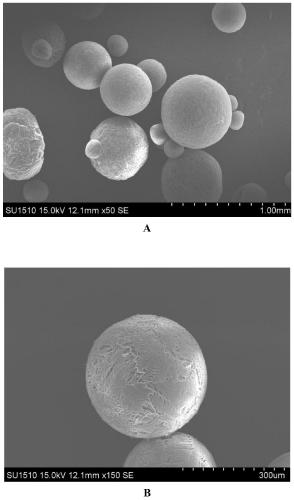

Embodiment 3

[0106] Chitosan powder (1.2g, degree of deacetylation is 98.7%, viscosity is 29mPa.s, purchased from Zhejiang Golden Shell Pharmaceutical Co., Ltd.) was added to 2% (w / v) glacial acetic acid aqueous solution (60mL), Dissolve at 65° C. for 5 h, and let stand for 24 h to obtain a bubble-free, uniform and transparent 2% (w / v) chitosan solution (60 mL).

[0107] Add type A gelatin (2.4g) with 250 freezing strength (double freezing strength) into deionized water (60mL), dissolve at 65°C, and let it stand for 24h to obtain stable and transparent 4% (w / v) gelatin solution (60 mL).

[0108] Mix the chitosan solution and the gelatin solution, and use a 13000rpm high-speed homogenizer to homogenize for 10 minutes to make them mix uniformly to obtain a chitosan-gelatin mixed solution with a solid content of 3.0%.

[0109] Put the chitosan-gelatin mixed solution in the atomizer of the spray freezing tower, and spray it into the cooling tower pre-cooled to -80°C, collect the frozen micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com