Polyurethane resin for synthetic leather surface layer, and preparation method thereof

A technology of polyurethane resin and synthetic leather, applied in the field of polyurethane resin, can solve the problems of insufficient temperature resistance of synthetic leather, large difference in leather feeling, damage to the surface layer, etc., and achieve the effect of soft hand feeling, good effect and outstanding wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

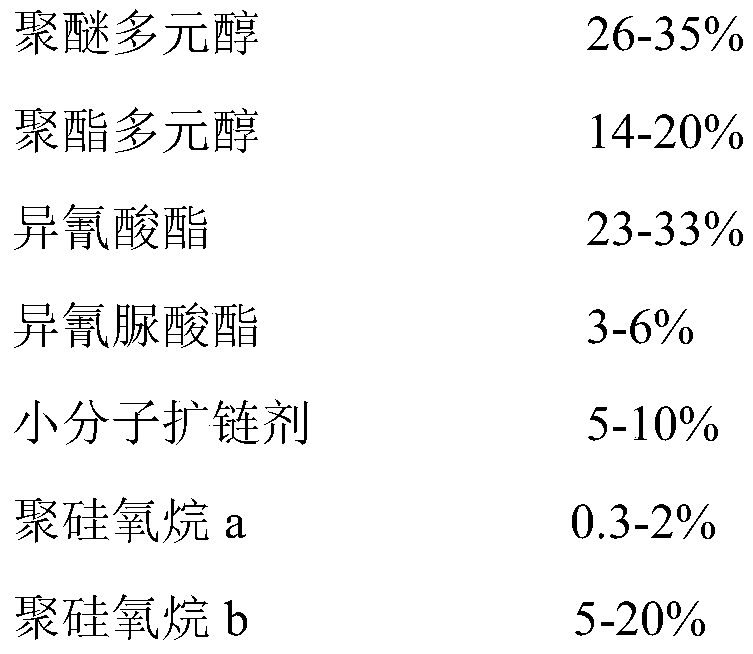

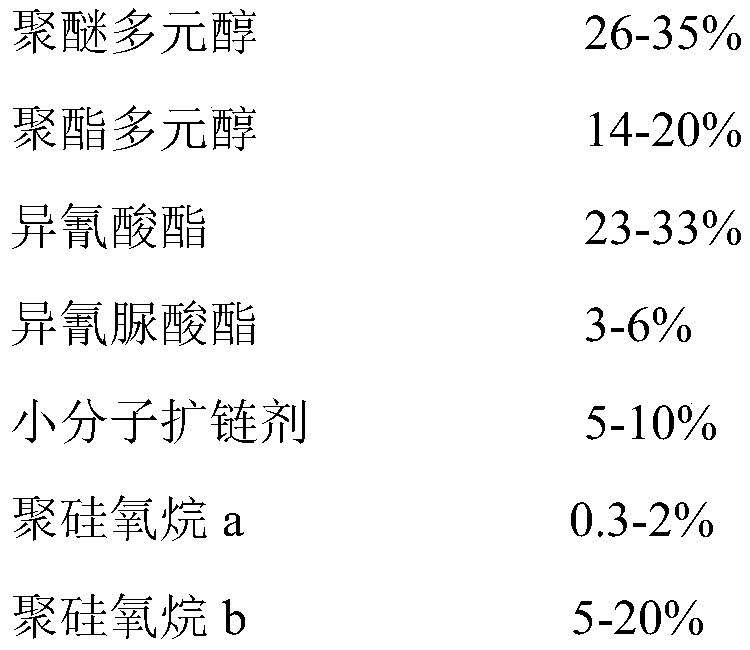

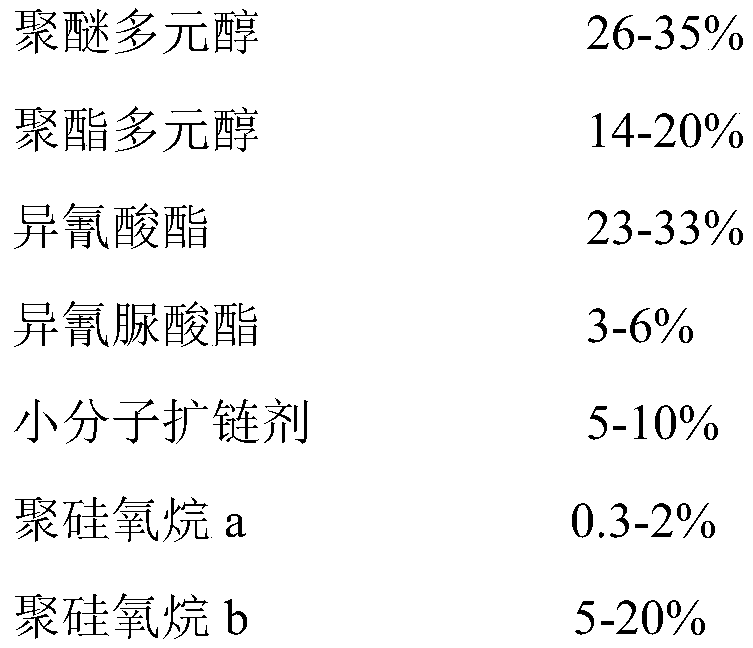

Method used

Image

Examples

Embodiment 1

[0059] (1) 17.2kg number-average molecular weight is 1000 neopentyl glycol adipate glycol, 35kg number-average molecular weight is 2000 polytetramethylene ether glycol, 1.9kg number-average molecular weight is 1000 amino-sealed The terminal polysiloxane and 100kg of solvent N,N-dimethylformamide were added to the reactor and stirred at 50°C until completely dissolved, then 5kg of diphenylmethane diisocyanate was added and the temperature was raised to 70°C for prepolymerization for 1 hour;

[0060] (2) Continue to add 6kg of diethylene glycol and 0.1kg of trimethylolpropane, lower the temperature to 50°C and stir for 30 minutes, add the catalyst dibutyltin dilaurate, and add 19.3kg of diphenylmethane diisocyanate to heat up to 70°C Continue to react for 0.5h;

[0061] (3) Add the remaining 200kg of solvent N,N-dimethylformamide until the viscosity reaches 110cps, then lower the temperature to 50°C and continue to stir for 1h, then add 5.2kg of hexamethylene diisocyanate to sel...

Embodiment 2

[0068] (1) 20kg number-average molecular weight is 2000 adipate-1,4-butanediol ester, 26kg number-average molecular weight is the polytetramethylene ether glycol of 3000, 1.5kg number-average molecular weight is the terminal hydroxyl of 2000 Add polysiloxane and 80kg solvent N,N-dimethylformamide to the reactor and stir at 40°C until completely dissolved, then add 3.8kg diphenylmethane diisocyanate and heat to 70°C for prepolymerization for 0.5h ;

[0069] (2) Continue to add 9.7kg 1,4-butanediol and 0.3kg trimethylolpropane, lower the temperature to 50°C and stir for 30 minutes, add the catalyst dibutyltin dilaurate, and add 29kg diphenylmethane diisocyanate to heat up Continue to react at 70°C for 0.5h;

[0070] (3) Add the remaining 100kg of solvent N,N-dimethylformamide until the viscosity reaches 118cps, then lower the temperature to 50°C and continue to stir for 1h, add 3kg of hexamethylene diisocyanate to self-polymerize to obtain a polymerization degree of 3 Compound...

Embodiment 3

[0077] (1) 14.4kg number-average molecular weight is 3000 adipate-ethylene glycol-1,4-butanediol ester glycol, 32.8kg number-average molecular weight is the polytetramethylene ether glycol of 2000, 0.3 Add kg of amino-terminated polysiloxane with a number average molecular weight of 1000, and 100 kg of solvent N,N-dimethylformamide into the reactor, stir at 55°C until completely dissolved, then add 4.3 kg of diphenylmethane diisocyanate and heat up Carry out prepolymerization at 80°C for 1 hour;

[0078] (2) Continue to add 5kg of ethanolamine and 0.2kg of trimethylolpropane, lower the temperature to 50°C and stir for 15 minutes, add the catalyst dibutyltin dilaurate, and add 21.9kg of diphenylmethane diisocyanate and heat up to 80°C to continue the reaction 1h;

[0079] (3) Add the remaining 100kg of solvent N,N-dimethylformamide until the viscosity reaches 120cps, then lower the temperature to 50°C and continue to stir for 1.5h, add 4.1kg of hexamethylene diisocyanate to se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com