Chocolate temperature-control homogenizer

A homogenizer and chocolate technology, which is applied in the field of food processing, can solve the problems affecting the quality of chocolate products, low efficiency, uneven heating, etc., and achieve the effects of outstanding taste and color, improved processing efficiency, and simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

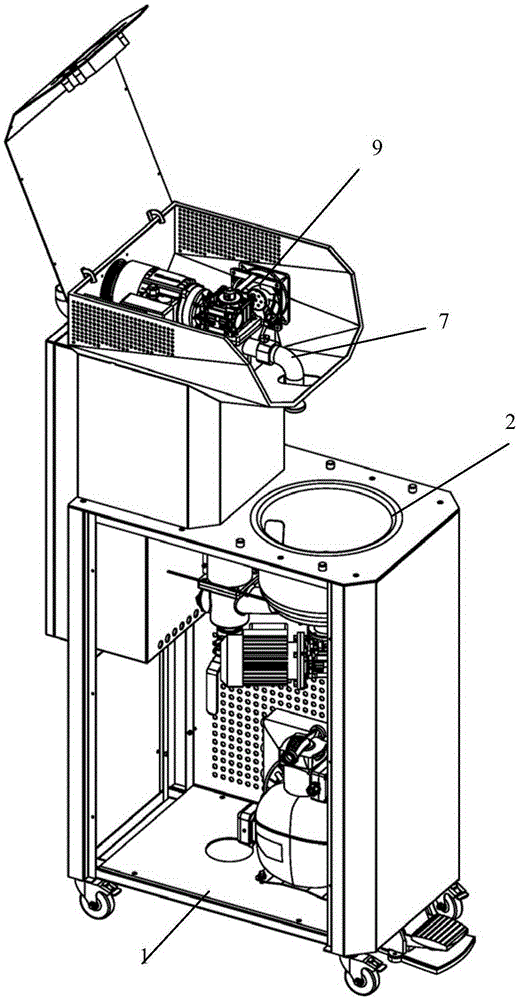

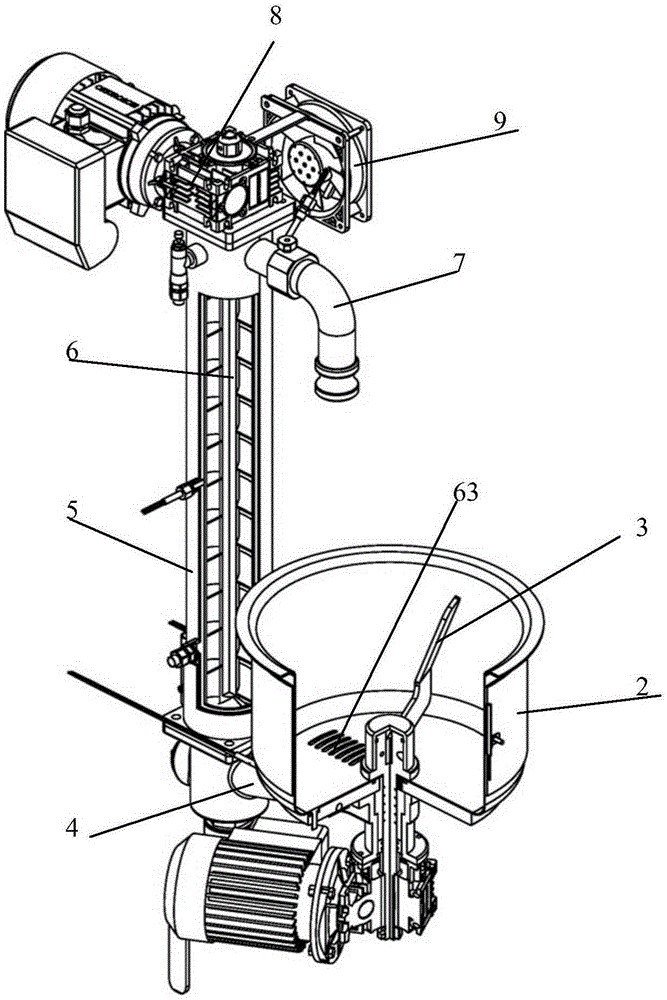

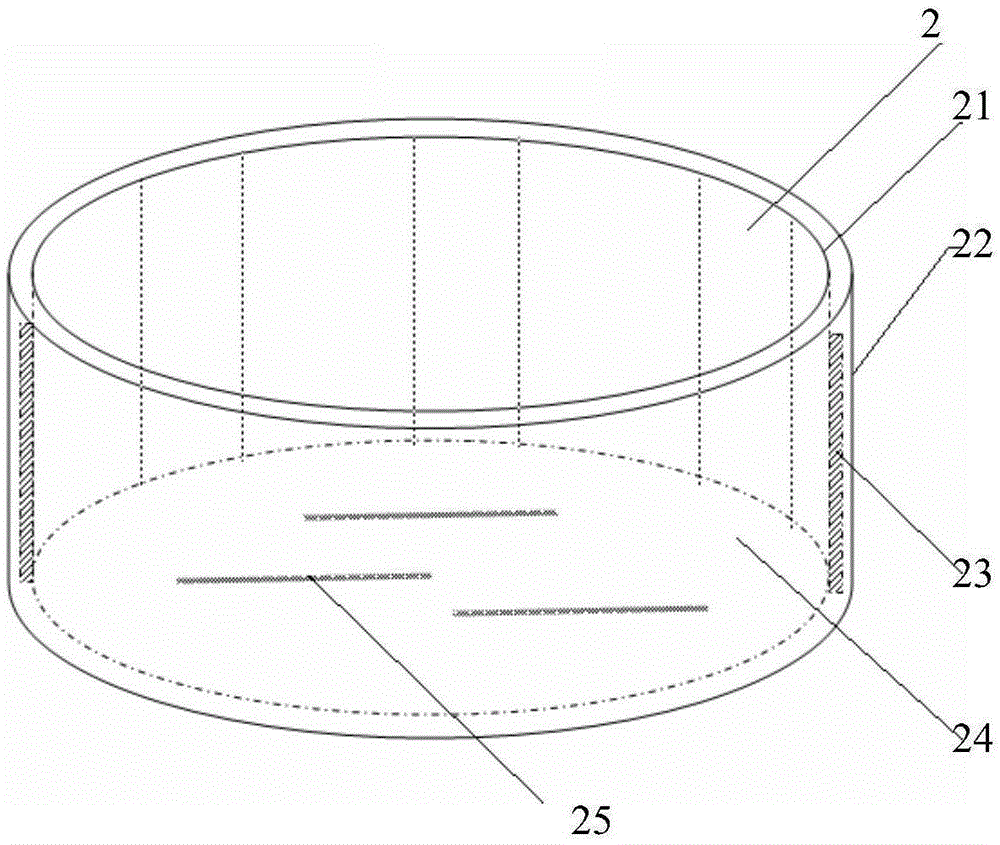

[0024] Such as Figure 1-5 As shown, the chocolate tempering and homogenizing machine of the present invention includes a heating and stirring part and a cooling conveying part, and the heating and stirring part includes a heating container 2 fixedly arranged on the frame body 1, and is arranged in the heating container to be stirred. The motor drives the stirring paddle 3 for rotating and stirring. The cooling conveying part includes a jacketed cylinder 5 connected to the bottom of the heating vessel through a connecting pipe 4 inclined downwards, and an auger 6 arranged in the cylinder. , and the discharge pipe 7 arranged at the discharge end of the cylinder.

[0025] The chocolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com