A table transfer transportation system for large slm equipment

A transportation system and workbench technology, applied in transportation and packaging, conveyor objects, conveyor control devices, etc., can solve the problems of manufacturing equipment and devices that cannot meet the requirements, and achieve convenient operation, convenient pick-up, and guaranteed reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

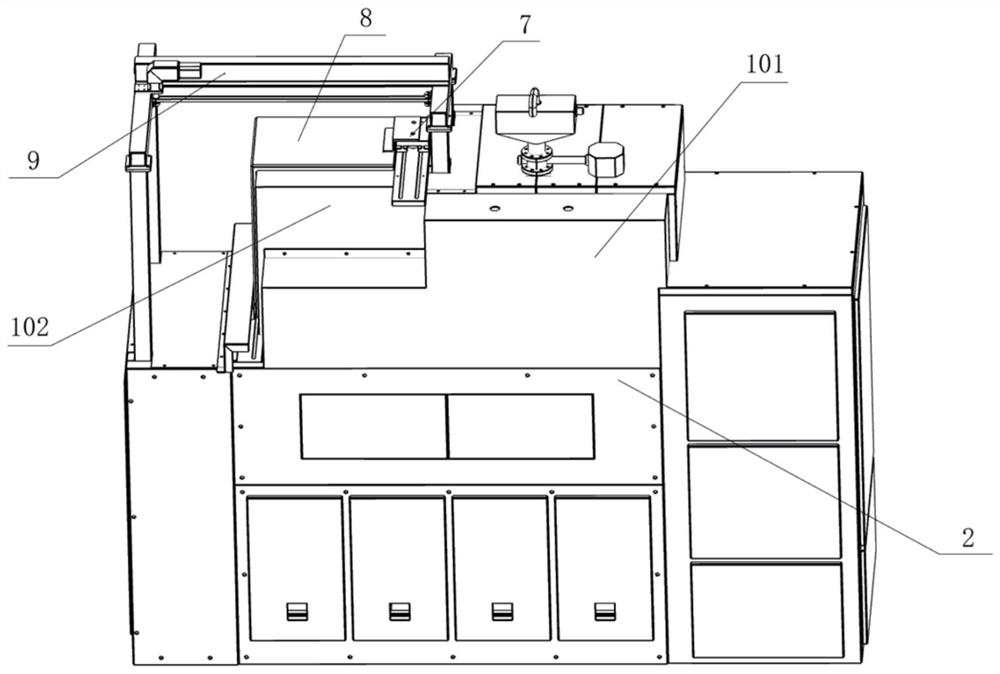

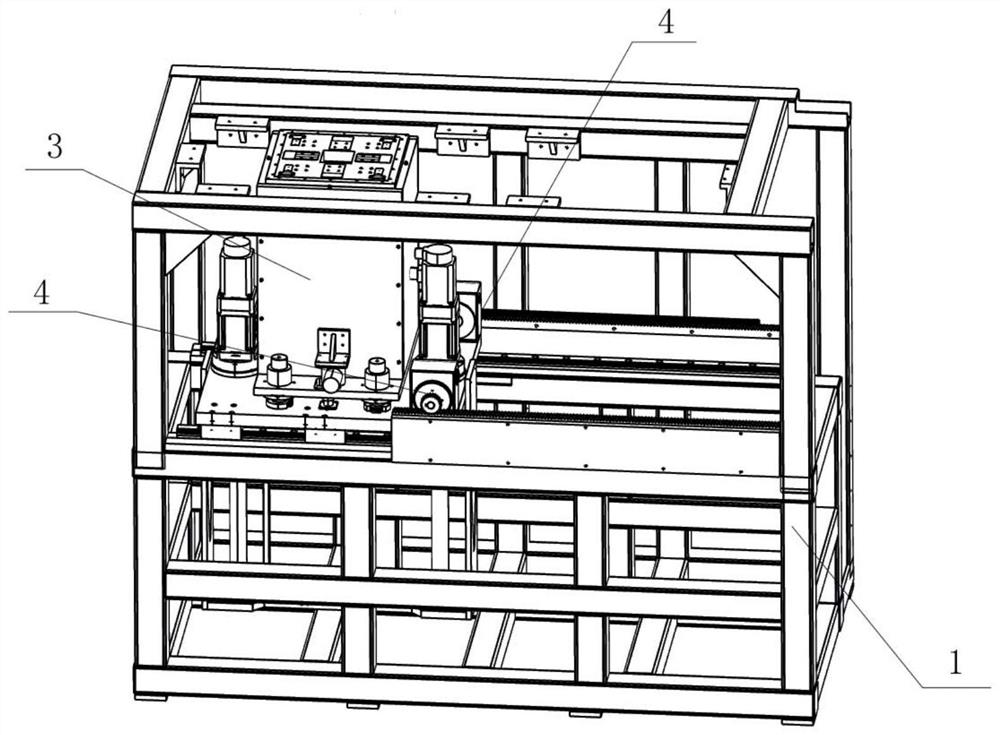

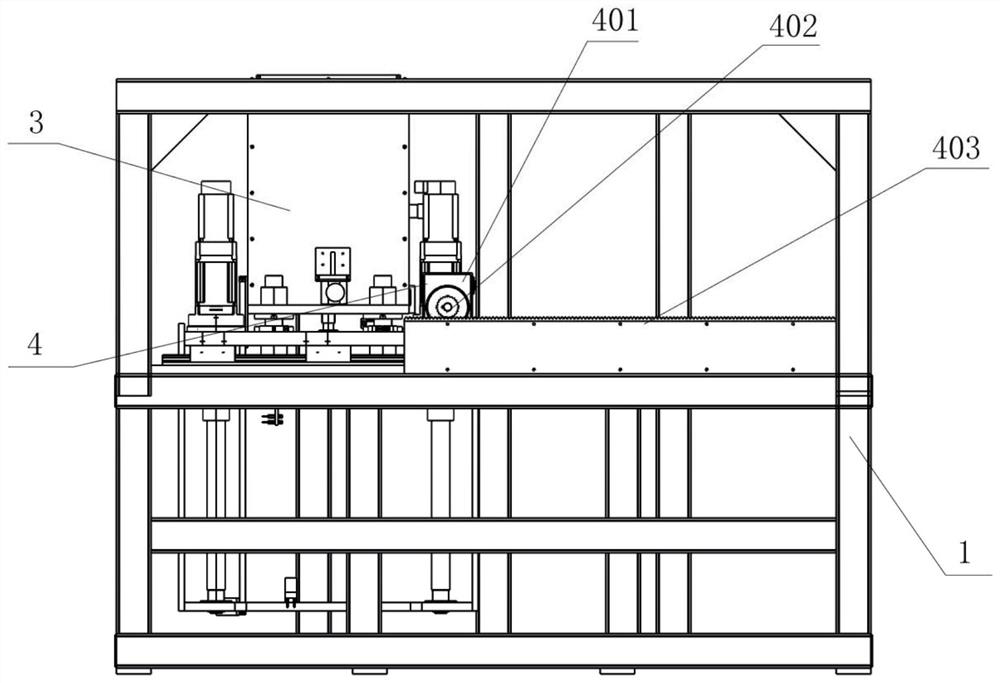

[0049] Such as figure 1 As shown, this embodiment provides a worktable transfer transportation system for large-scale SLM equipment, which is used to transfer worktables. The worktable transfer transportation system includes a frame body 1, a housing 2, a worktable driving device, and a limit device 6 , the automatic pick-up device 9 and the power supply for the entire system, the frame body 1 includes a work area 101 and a pick-up area 102, the housing 2 is arranged on the outside of the frame body 1, and the workbench driving device is respectively connected to the frame body 1 and the workbench, It is used to drive the workbench to move between the work area 101 and the pick-up area 102. The limit device 6 is respectively connected to the frame body 1 and the workbench for detecting the moving position of the workbench. The automatic pick-up device 9 is connected to the frame body 1. It is used to automatically pick up the formed parts in the pick-up area 102.

[0050] The...

Embodiment 2

[0079] This embodiment is substantially the same as Embodiment 1, the difference is that a proximity sensor is respectively provided in the blocking blocks at both ends of the guide rail 602 in the limiting device 6 to detect the main body of the limiting block, so as to realize the transmission of the workbench for detection , further preventing the movement of the workbench beyond the length range of the rack and the slide rail, improving the reliability and automation level of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com