Coal gangue downhole processing method

A processing method, coal gangue technology, applied in grain processing, chemical instruments and methods, wellbore lining, etc., can solve problems such as occupation, environmental pollution, large land, etc., to increase safety, increase coal quality, reduce transportation costs and The effect of pollution on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

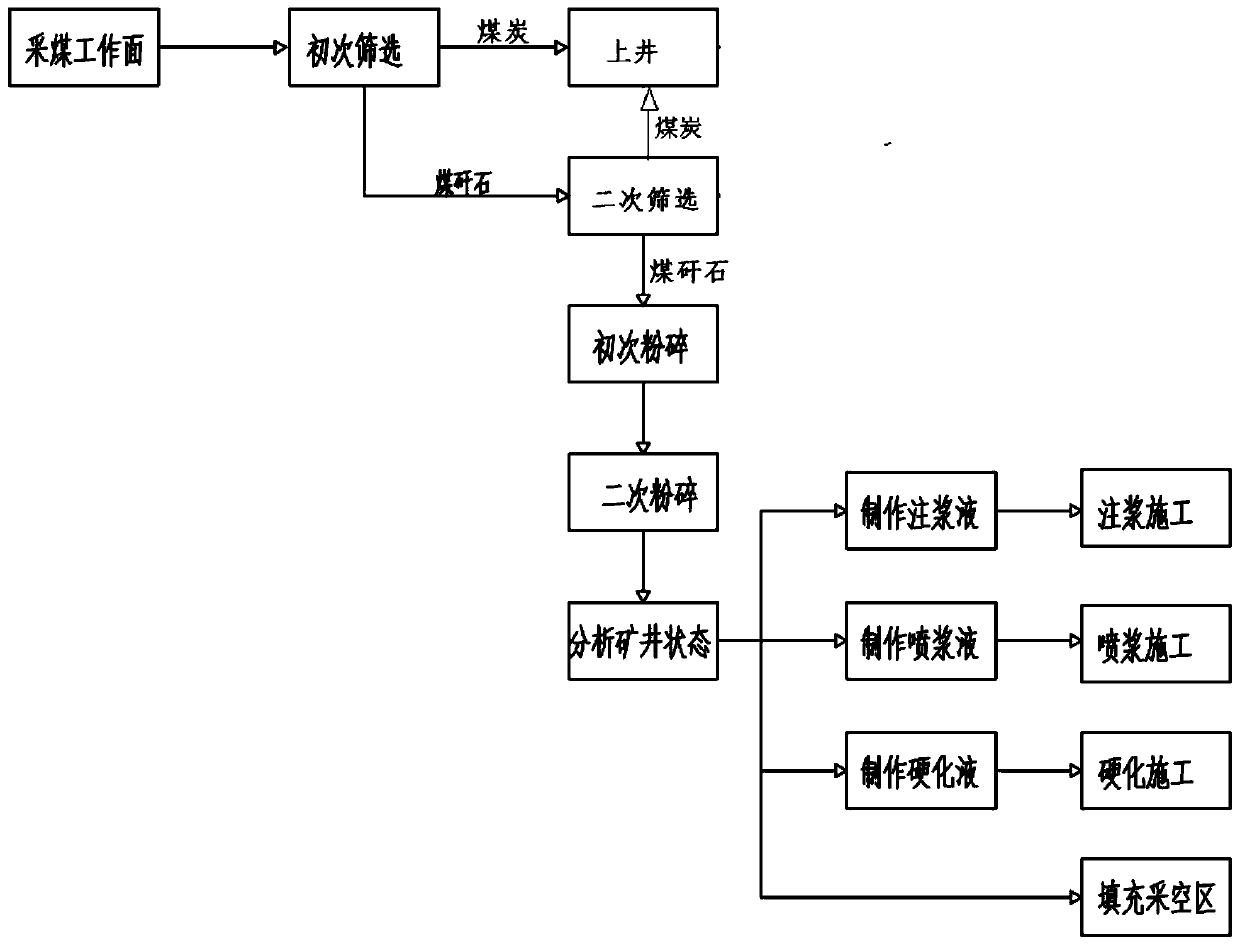

[0029] This embodiment discloses a coal gangue underground processing method, comprising the following steps:

[0030] The initial screening of the mine resources mined in the coal mining face is carried out, and the mined raw materials are put into the gear-type roller screen. The gear-type roller screen is composed of rolling shafts arranged horizontally. There is a plate, and the fine-grained material passes through the gap between the rollers or plates, and the large material is driven by the roller to move to the other end and discharged from the end. At the same time, it has the function of crushing, and the coal can be separated according to the hardness difference between coal and gangue. Screen out large pieces of coal and coal gangue, and keep small pieces of coal and coal powder. After secondary screening of bulk coal and coal gangue, the coal gangue is transported to the gangue warehouse through the belt for storage.

[0031] The secondary screening adopts TDS int...

Embodiment 2

[0035] The initial screening of the mine resources mined in the coal mining face is carried out, and the mined raw materials are put into the gear-type roller screen; the gear-type roller screen is vibrating screening, which can screen out large pieces of coal and coal gangue, and keep small pieces Coal and pulverized coal. After secondary screening of bulk coal and gangue, the bulk coal gangue is transported to the gangue warehouse by belt for storage.

[0036] The secondary screening adopts TDS intelligent screening machine to screen and separate bulk coal and coal gangue through X-ray screening. The screened coal is transported to the mine for storage and sales, and the coal gangue is transported to the gangue warehouse through the conveyor belt for storage.

[0037] Put the coal gangue stored in the gangue bin into the jaw crusher for primary crushing. The jaw crusher can crush large pieces of coal gangue into small pieces. The coal gangue that has been crushed for the f...

Embodiment 3

[0040] The initial screening of the mine resources mined in the coal mining face is carried out, and the mined raw materials are put into the gear-type roller screen; the gear-type roller screen is vibrating screening, which can screen out large pieces of coal and coal gangue, and keep small pieces Coal and pulverized coal. After secondary screening of bulk coal and gangue, the bulk coal gangue is transported to the gangue warehouse by belt for storage.

[0041] The secondary screening adopts TDS intelligent screening machine to screen and separate bulk coal and coal gangue through X-ray screening. The screened coal is transported to the mine for storage and sales, and the coal gangue is transported to the gangue warehouse through the conveyor belt for storage.

[0042] Put the coal gangue stored in the gangue bin into the jaw crusher for primary crushing. The jaw crusher can crush large pieces of coal gangue into small pieces. The coal gangue that has been crushed for the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com