Preparation method and application of iron oxyhydroxide modified vermiculite composite adsorbing material for removing Mn from underground water

A composite adsorption material, iron oxyhydroxide technology, applied in chemical instruments and methods, contaminated groundwater/leachate treatment, adsorption water/sewage treatment, etc., can solve the problem of manganese content in groundwater exceeding the standard treatment function, rural drinking water is difficult to obtain safety Guarantee and other issues, to achieve the effect of no secondary pollution, high-efficiency adsorption performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In order to make the preparation method and application of the present invention easy to understand, the present invention will be further described below in conjunction with specific examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0043] In this embodiment, the adsorption removal rate of the adsorbent to Mn(II) is calculated by the following formula:

[0044] (Initial Mn(II) concentration - Residual Mn(II) concentration after reaction)*100% / Initial Mn(II) concentration

[0045] The adsorption capacity of the adsorbent to Mn(II) is calculated according to the following formula:

[0046] (Initial Mn(II) concentration-residual Mn(II) concentration after reaction)*solution volume / adsorbent dosage

Embodiment 1

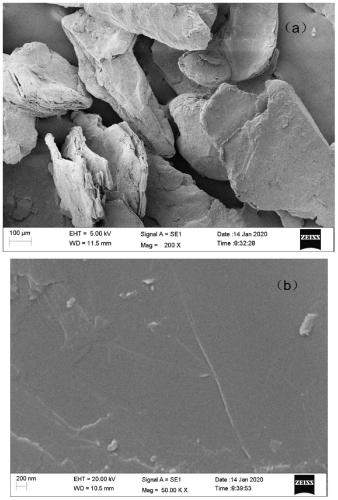

[0048] In this example, the preparation method of iron oxyhydroxide modified vermiculite composite adsorption material is as follows:

[0049] Step 1: Take 10g of natural vermiculite, wash it with deionized water for 10-15 times, then add it to 200ml0.01mol / L dilute hydrochloric acid solution, stir and react for 2h, and wash the vermiculite after pickling with deionized water until The lotion is near-neutral (PH value is 6.5-7.5), put it into a thermostat at 105°C and dry to constant weight, pass through 40-mesh and 60-mesh sieves to obtain pretreated vermiculite with a particle size of 40-60 mesh;

[0050] Step 2: mix the vermiculite of 6g pretreatment with 200ml 0.25mol / L Fe(NO 3 ) 3 The solution was stirred and mixed, impregnated and shaken with 400W ultrasonic wave at room temperature for 30 minutes, then adjusted to pH 12 with alkaline solution, stirred and reacted for 60 minutes, aged in a constant temperature oven at 60°C for 48 hours, cooled, filtered and separated to...

Embodiment 2

[0059] The preparation method of the ferric oxyhydroxide modified vermiculite adsorption material is the same as Step 1 and Step 2 of Example 1.

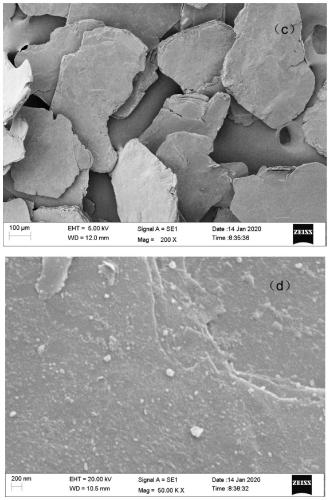

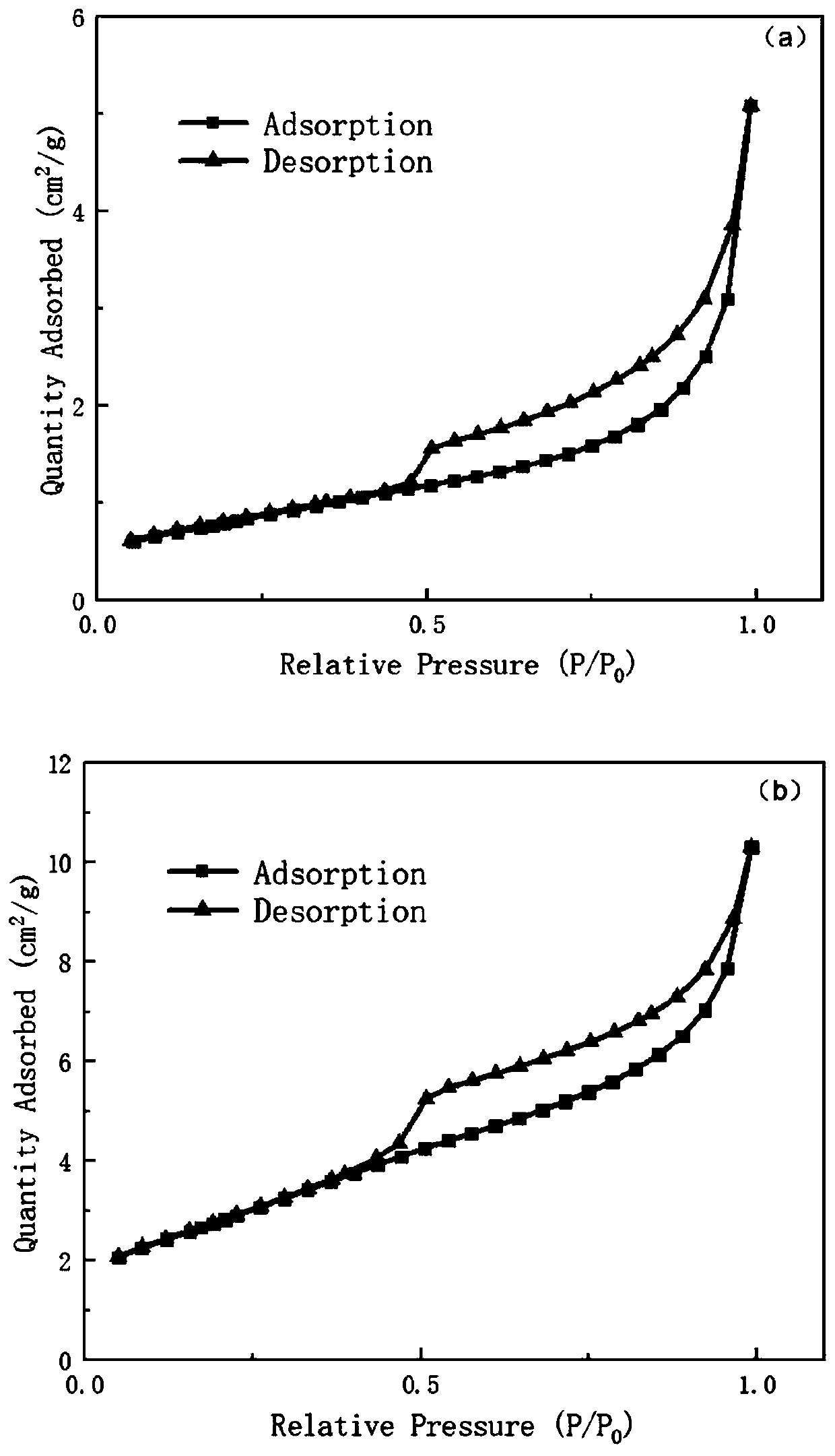

[0060] Step 3: Weigh 0.1000g (±0.0005g) of the above-mentioned obtained composite adsorption material and unmodified vermiculite, put them into a 250ml Erlenmeyer flask with a stopper respectively, and add 100mL Mn(II) with an initial concentration of 3mg / L thereinto ) water sample, placed in a constant temperature oscillator, fully oscillated (150r / min) at a temperature of 25°C, and stopped oscillating after absorbing for 180min;

[0061] Step 4: Take the supernatant after shaking in step 3 and pass it through a 0.45 μm microporous membrane, and measure the remaining Mn(II) concentration in the filtrate with a Shimadzu AA-7000 atomic absorption spectrophotometer. The results show that: for the water sample with an initial concentration of 3mg / L Mn(II), the adsorption capacity of vermiculite for adsorbing Mn(II) is 1.80mg / g, while t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com