Heart prosthesis valve

An artificial heart and prosthesis technology, applied in the field of medical devices, can solve problems such as adverse postoperative effects, reduce stent fatigue performance, affect cardiac contraction, etc., and achieve the effect of reducing the difficulty of grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

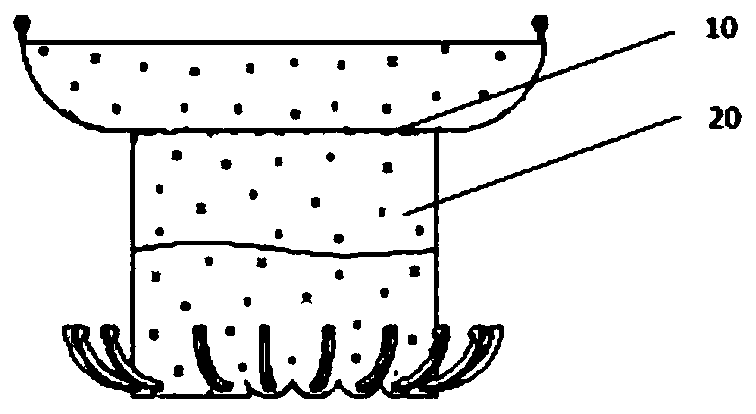

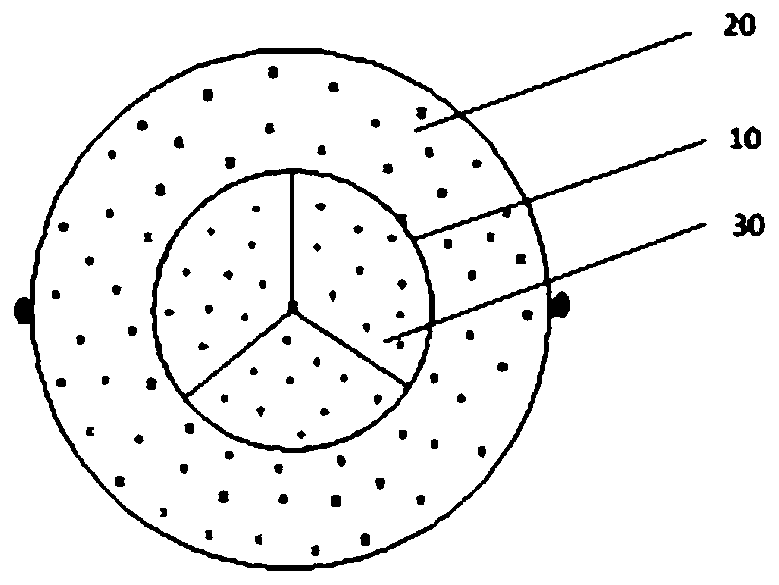

[0062] like figure 1 , figure 2 As shown, an interventional prosthetic heart valve includes a stent body 10 , a skirt 20 and a leaflet 30 .

[0063] Stent 10 (that is, the supporting and positioning structure of the prosthetic heart valve, used for bearing leaflets, attaching skirts, anchoring and positioning, etc.) is made of shape memory alloys, such as NiTi (nickel-titanium alloy), CuAlNi (copper-aluminum-nickel alloy) Wait. In this embodiment, NiTi is preferred.

[0064] The skirt 20 (that is, one or more layers of film attached to the inner surface or outer surface or both surfaces of the stent and has functions such as sealing and preventing paravalvular leakage) is made of polymer materials, such as PTFE (polytetrafluoroethylene), PET (polyethylene terephthalate), etc. The skirt 20 can also be made of biological tissue materials such as animal pericardium.

[0065] The valve leaflet 30 (i.e., the artificial valve leaflet, which is used to replace the original fail...

specific Embodiment approach

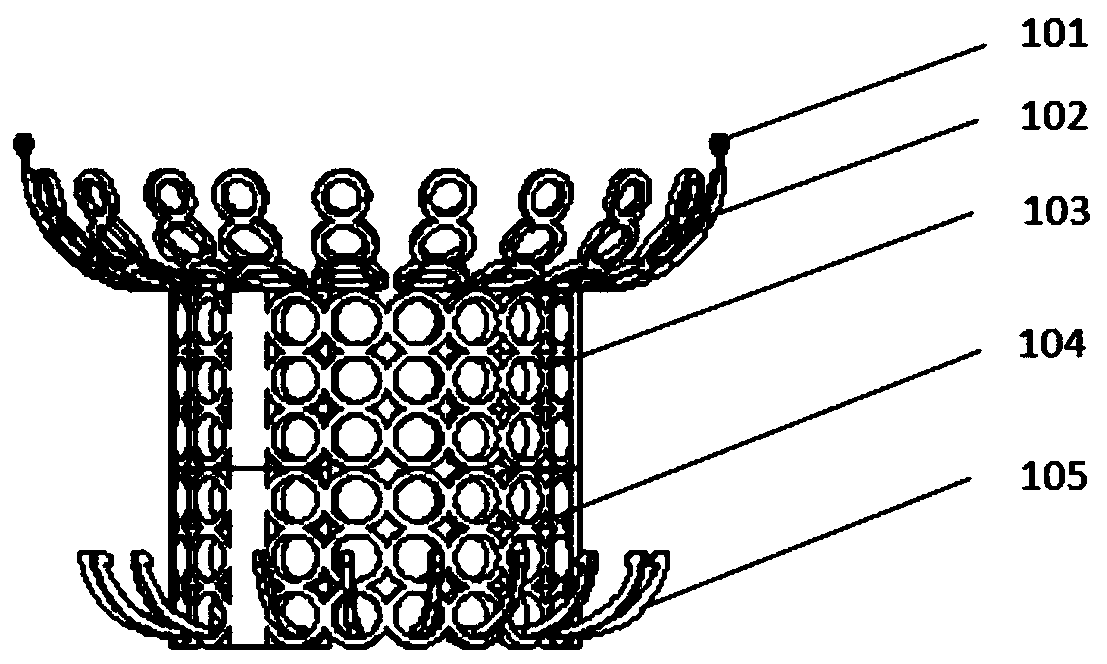

[0207] 1. Prosthetic valve loading process:

[0208] like Figure 20 As shown, the delivery device is basically composed of Tip head, traction rope, sheath tube, fixed ear and fixed head. In addition to the components shown in the figure, there are also conventional components such as manual or electric handles, catheters, and guide wires. This embodiment No elaboration on this.

[0209] ①The prosthetic valve was loaded in an ice-water bath below 5°C outside the body.

[0210] ② Connect the upper bracket 103 and the lower bracket 103 with the traction rope sent from the loading tool.

[0211] ③The prosthetic valve is compressed to a smaller size through a special loading tool and loading method, and then the fixed ear 101 is snapped into the fixed ear hole, and the prosthetic valve is completely wrapped in the sheath by pulling the fixed head.

[0212] ④ Fill the sheath with saline, etc., empty the air inside, and then push the sheath to fit the tip completely to achieve a ...

Embodiment 2

[0224] Other structures in this embodiment are the same as in Embodiment 1, except that the structures of the straight sleeve and straight rod are different from Embodiment 1.

[0225] The straight sleeve 2033 is provided with a T-shaped hollow area, and its cross section is T-shaped. The hollow inner wall of the straight sleeve 2033 is provided with a plurality of grooves at intervals. In the embodiment, the straight sleeve 2033 is a hollow columnar rod with a trapezoidal cross-section. The groove 20331 of the axis of the straight sleeve 2033, such as Figure 21 As shown, the groove 20331 is a groove in the hollow area of the straight sleeve 2033 .

[0226] Preferably, the grooves 10331 are evenly and continuously distributed in all hollow areas of the straight sleeve 2033 .

[0227] The groove 20331 should be slightly larger than the buckle 20411 to complete mutual matching.

[0228] The straight rod 2041 is a columnar rod inserted in the two lower bracket walls 1042, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com