Low-cost high-power-density single-phase high-speed permanent magnet motor and method

A high power density, permanent magnet motor technology, used in AC motor control, synchronous motors with stationary armatures and rotating magnets, electric components, etc. and other problems, to achieve the effect of improving performance and power density, reducing manufacturing costs, and avoiding magnetic performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

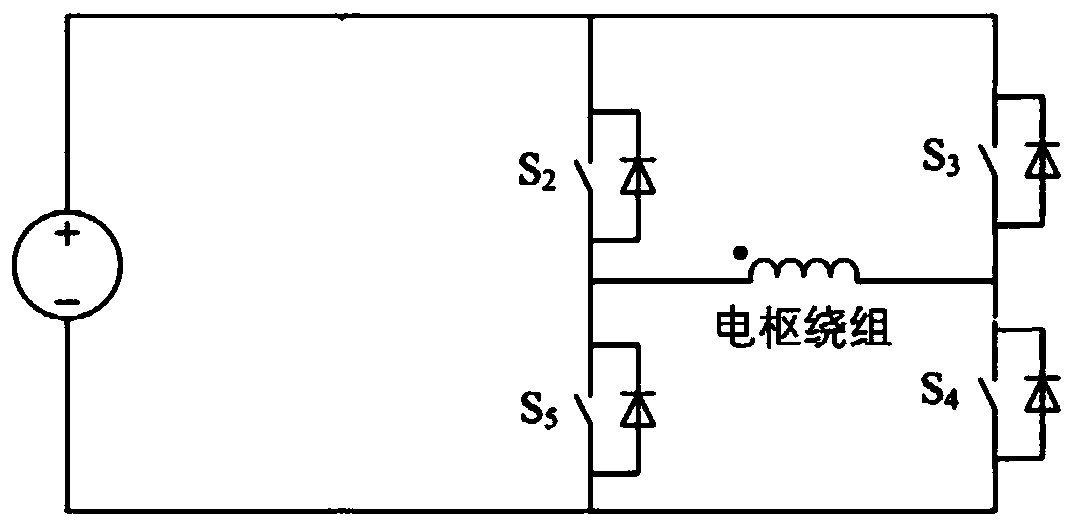

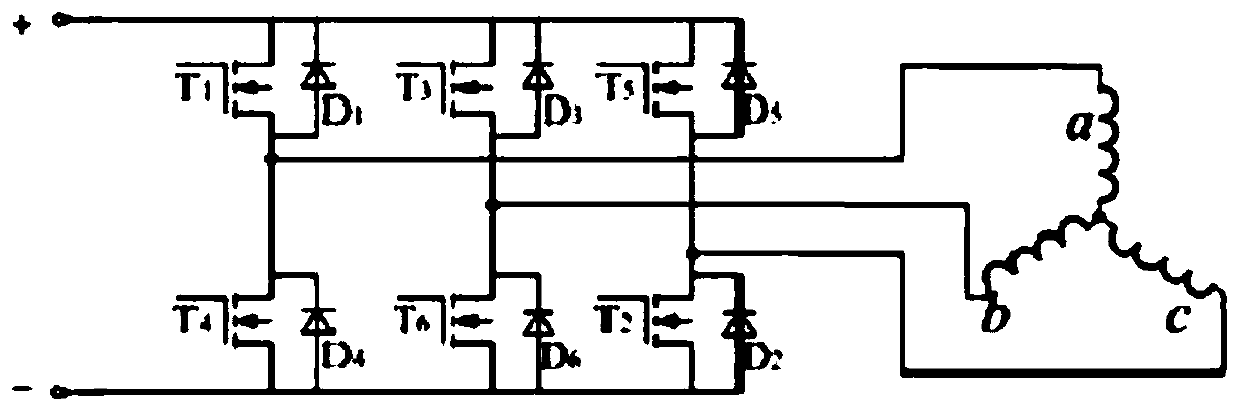

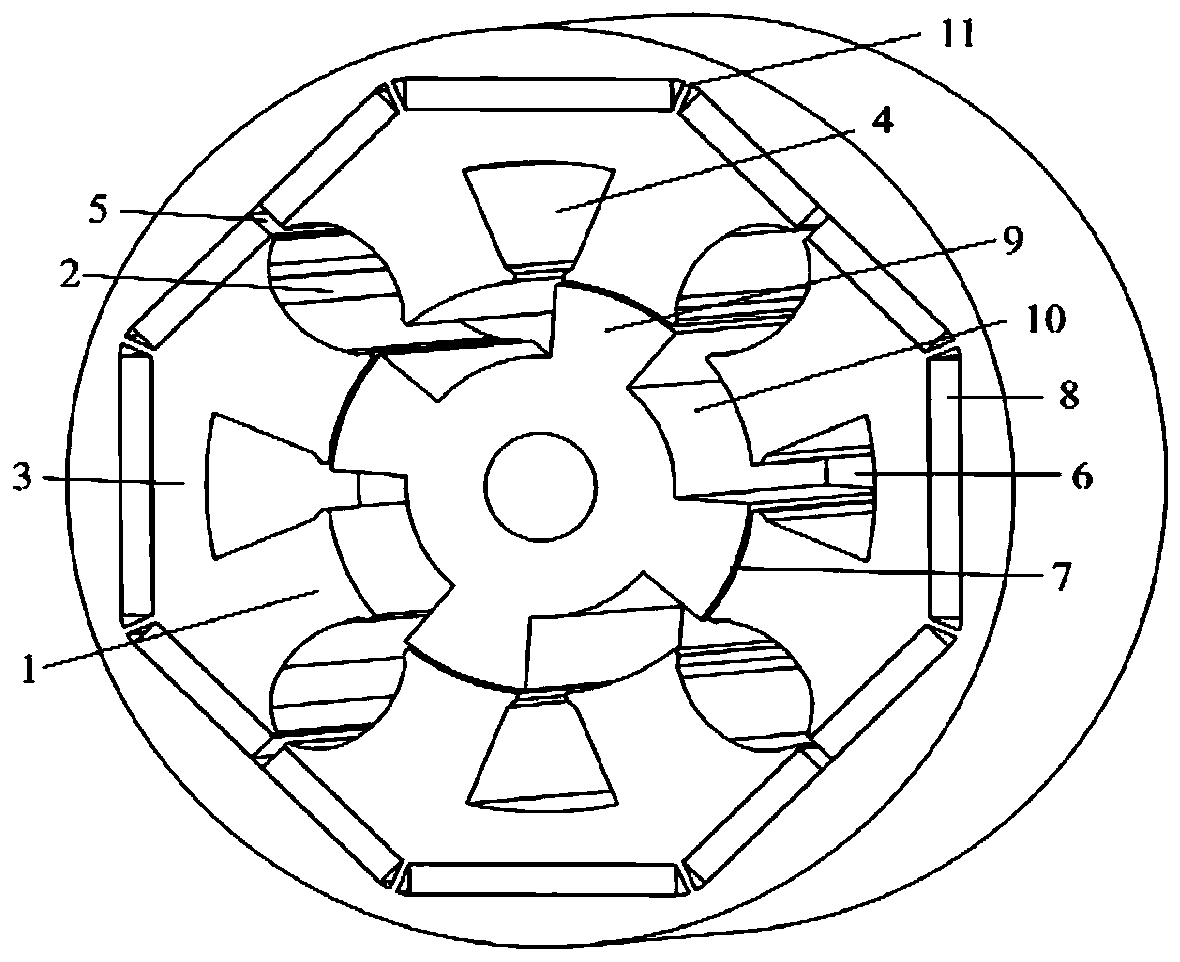

[0055] This embodiment discloses a low-cost high-power-density single-phase high-speed permanent magnet motor, including a stator and a rotor. The stator is composed of stator slots, stator teeth, stator yokes and permanent magnet slots. The armature slots are close to the iron core. A permanent magnet groove is arranged on the outer periphery, and a permanent magnet is arranged in the permanent magnet groove. The armature slots are arranged along the circumference, and a set of armature windings is placed in the armature slots; the rotor includes rotor teeth, rotor slots are provided between adjacent rotor teeth, and a main air gap is provided between the stator teeth and rotor teeth; The stator between the permanent magnets with opposite polarities is radially disconnected and has air slots. The shape of the air slot is based on the optimization results, and the pear-shaped air slot is selected to improve the performance of the motor and allow more magnetic flux to pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com