A Double Winding High Power Density Hybrid Excitation Permanent Magnet Linear Generator

A high power density, hybrid excitation technology, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problems of high slot full rate, poor heat dissipation of permanent magnets, etc., to achieve low manufacturing cost, avoid magnetic The effect of energy reduction and high slot utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

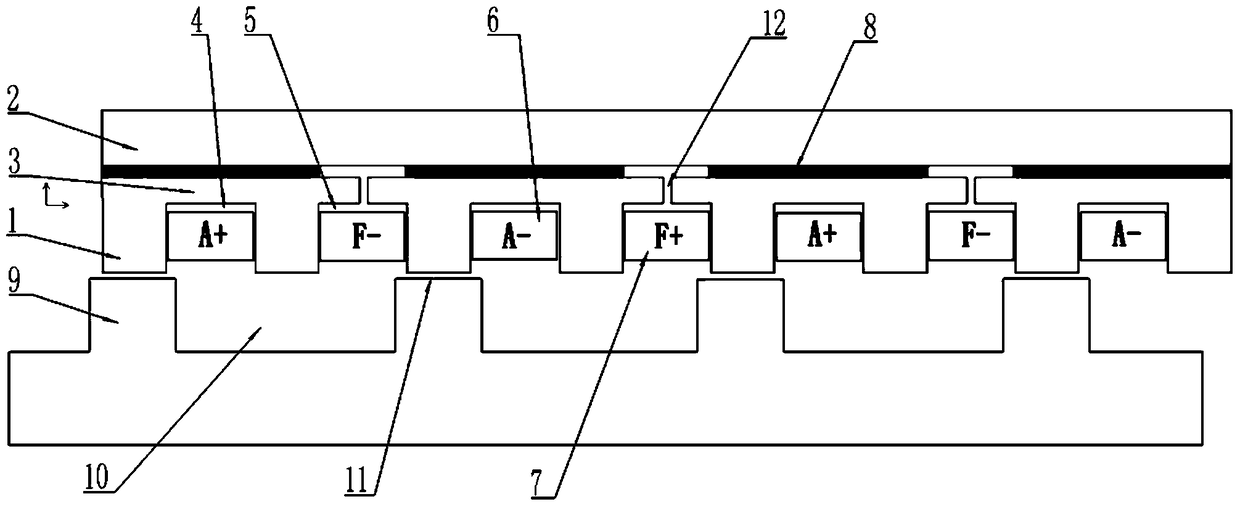

[0063] like image 3 As shown, the number of stator teeth of the motor is 8, the number of mover teeth is 4, and the number of permanent magnet blocks is 4. This embodiment includes a stator, a mover, a main air gap and an additional air gap, and the stator includes a stator core, a permanent magnet and a stator slot , the stator core includes stator teeth 1, stator back yoke 2 and stator slot yoke 3, the stator core is made of ferromagnetic material with high magnetic permeability, the stator core is provided with stator slots, the stator slot includes armature slot 4 and excitation Slots 5, armature slots 4 and excitation slots 5 are alternately arranged at intervals, and armature windings 6 are placed in armature slots 4, and armature windings 6 pass through one armature slot 4 and pass through another adjacent armature slot. A coil is formed so that the currents in every two adjacent armature slots are the same in size and opposite in direction, and an excitation winding 7...

Embodiment 2

[0065] like Figure 4 As shown, the number of stator teeth of the motor is 8, the number of teeth of the mover is 4, and the number of permanent magnet blocks is 8. This embodiment includes a stator, a mover, a main air gap and an additional air gap, and the stator includes a stator core, permanent magnets and stator slots , the stator core includes stator teeth 1, stator back yoke 2 and stator slot yoke 3, the stator core is made of ferromagnetic material with high magnetic permeability, the stator core is provided with stator slots, the stator slot includes armature slot 4 and excitation The slot 5, the armature slot and the excitation slot are alternately arranged at intervals, and the armature winding 6 is placed in the armature slot 4, and the armature winding 6 penetrates through one armature slot and passes through another adjacent armature slot, forming One coil, so that the currents in every two adjacent armature slots have the same magnitude and opposite directions, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com