Packaged large-area perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of unsuitability for single-chip module power generation, large series resistance, insufficient module voltage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

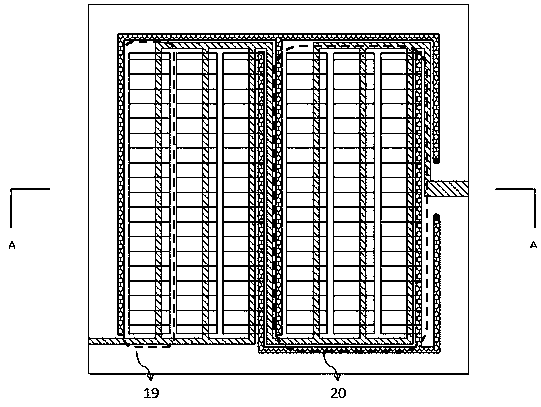

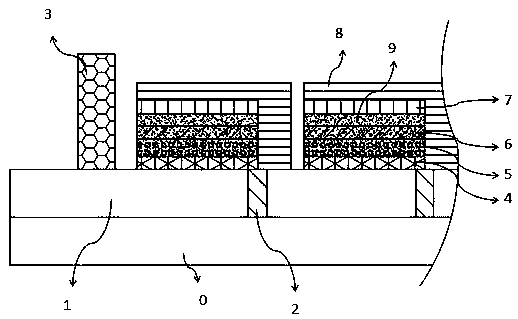

[0079] made as Figure 5 The battery with 19 small units in series and 2 large units in parallel, the specific steps are as follows.

[0080] (1) Use a laser to make holes on the transparent conductive substrate, and etch away the conductive FTO layer to ensure infinite resistance between units.

[0081] (2) Use acetone, alkaline detergent, deionized water, and acetone to ultrasonically clean the FTO glass for ten minutes, and finally blow dry.

[0082] (3) Preparation of TiO on FTO glass substrate 2 Dense layer, the solvent is terpineol, which includes the following components: 1.5ml tetraisopropyl titanate, 3.5g ethyl cellulose, 80ml terpineol, coated on a clean FTO substrate, in a muffle furnace at 510 ℃ sintering for 30min.

[0083] (4) On the dense layer, screen-print titanium dioxide paste as the electron transport layer, with a solid content of 10%, solvent terpineol, and sinter in a muffle furnace at 510 ° C for 30 min.

[0084] (5) On the electron transport layer,...

Embodiment 2

[0098] The preparation and packaging process of the battery is the same as that of Example 1, and will not be repeated here.

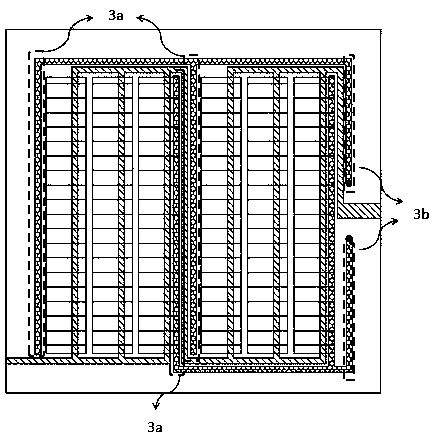

[0099] Specific preparation such as Figure 6 A structure in which 4 small units are connected in series and 11 large units are connected in parallel can be formed, for example, as follows:

[0100] The short side of the small unit is close to the etching line, and the part of the small unit (hole blocking layer, electron transport layer, insulating layer and hole transport layer) except the counter electrode (positive electrode) covers the etching line side (upper side) On the conductive layer (negative electrode) on the transparent conductive substrate, the counter electrode vertically spans the etched line to the other side (lower side), covering the conductive grid line (negative electrode) on the lower side of the etched line. The positive and negative poles in the unit are separated by an insulating layer. The anode of the unit above the etchin...

Embodiment 3

[0102] The preparation and packaging process of the battery is the same as that of Example 1, and will not be repeated here.

[0103] Specific preparation such as Figure 4 A structure in which 3 small units are connected in parallel and 2 large units are connected in series can be formed, for example, as follows:

[0104] The middle longitudinal etching line divides the conductive layer on the transparent conductive substrate into two large units, left and right. In the large unit on the left, the conductive grid lines are distributed in the small unit gap, collecting electrons (negative pole) on the conductive layer to the upper left hole to form the negative pole of the module; the short side of the lower side of the three small units is close to the etching line, and the small unit The part (hole blocking layer, electron transport layer, insulating layer, and hole transport layer) other than the counter electrode (positive electrode) covers the conductive layer (negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com