High-voltage reference electrode, preparation method and application

A reference electrode and high-voltage parameter technology, applied in the field of deep-sea high-voltage electrochemistry, can solve the problems of loss of accurate measurement of electrode potential, easy damage of electrode wires, broken silver wires, etc., to improve sealing, practicability, and data reliability. Strong, not easily polarized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

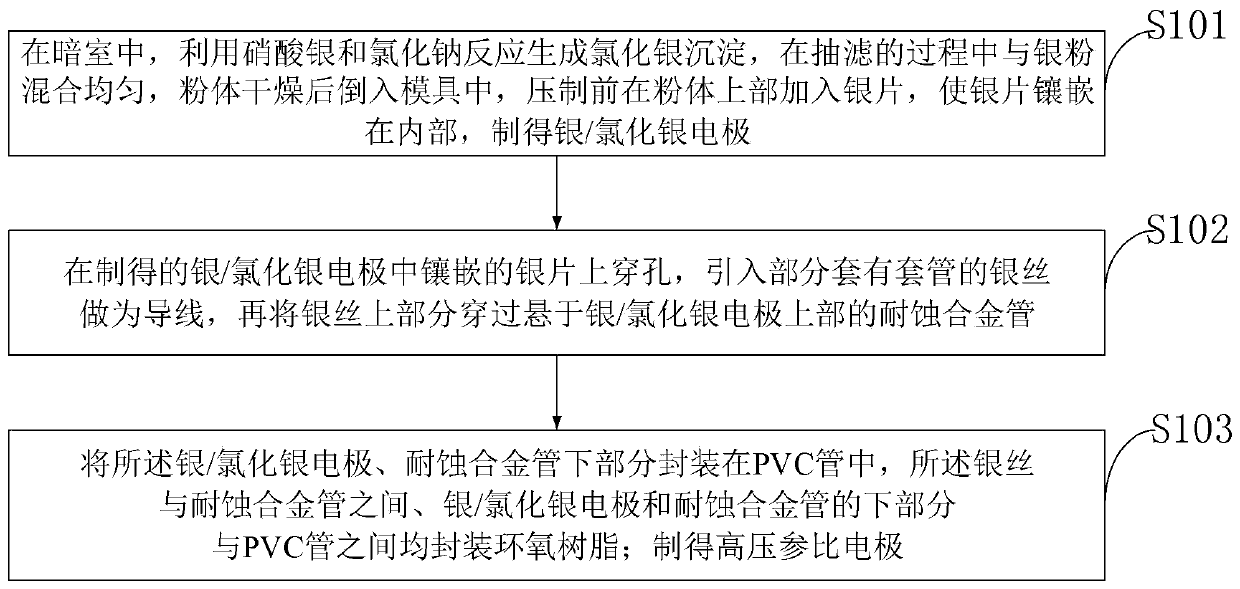

[0039] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

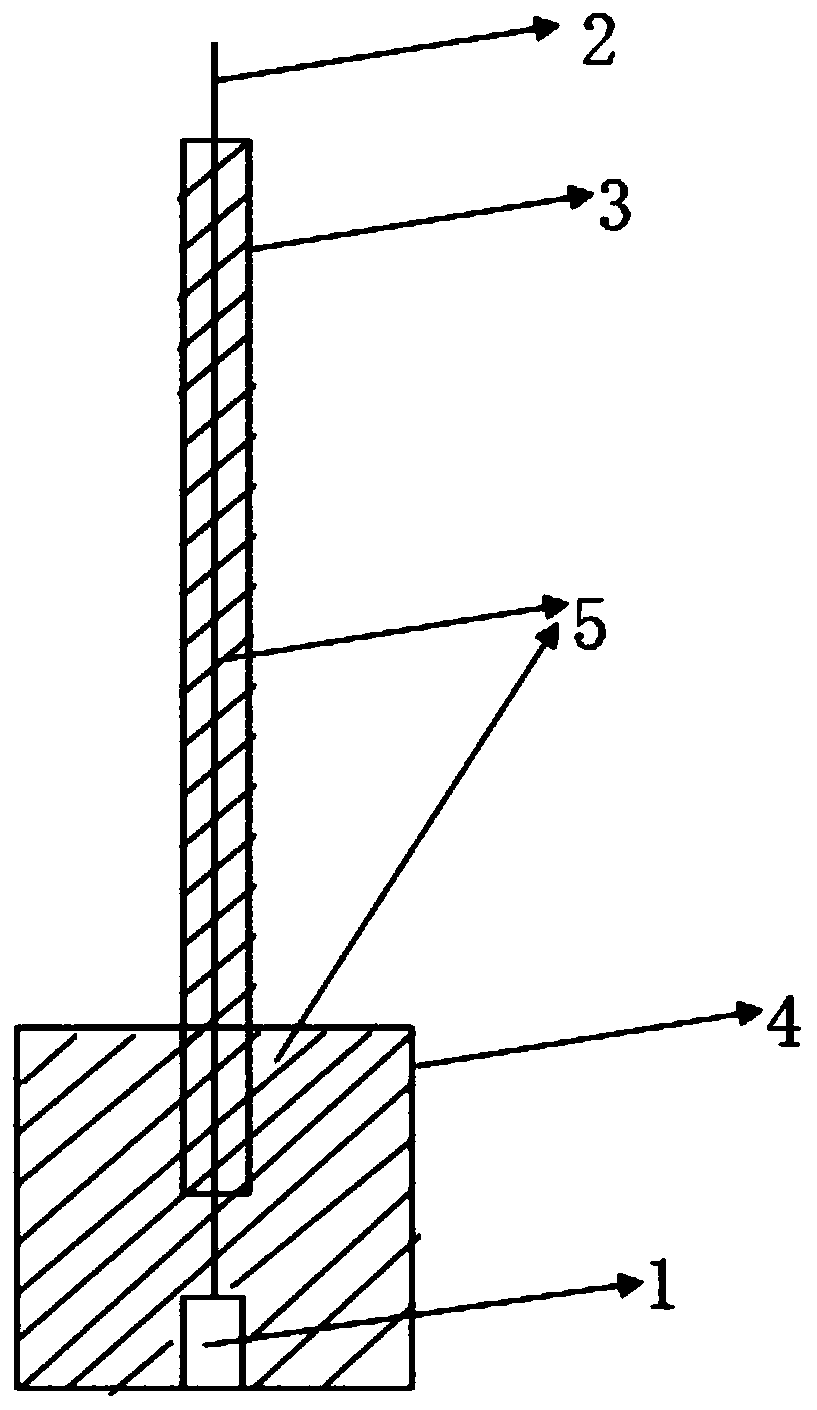

[0040] In the existing technology, in order to overcome the difficulty in connecting the electrodes and the wires, direct welding is not possible, and at the same time, after the wires are led out, the common packaging form has poor airtightness, which causes great difficulties in use. Some use the silver wire part to be pressed into the powder. , leave a part as the lead wire for welding, but it is easy to break the silver wire in the process of making electrodes in this form, which limits the electrode making. In terms of packaging, in the prior art, the electrodes are directly packaged in PVC pipes with epoxy resin, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com