Powder dispersion and drying device

A drying device and dispersing technology, which is used in the preliminary treatment of promoting the drying of solid materials, drying of solid materials, and the treatment of dry goods, etc., can solve the problems of poor process continuity, increased production cost, easy occurrence of dead ends, etc., and achieves simple and simplified operation. Production and processing procedures, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is further described:

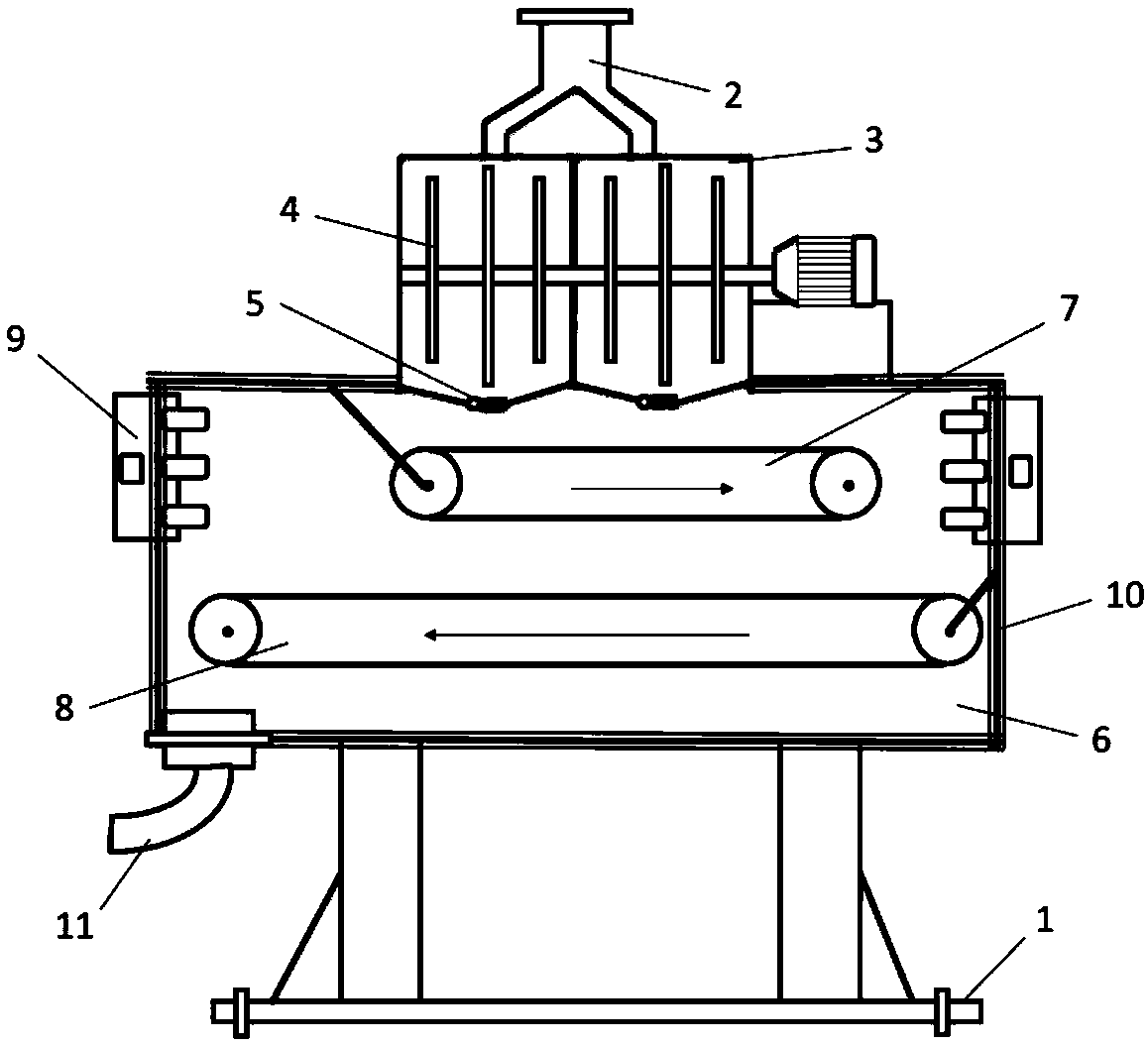

[0014] see figure 1 , a powder dispersing and drying device, comprising a base frame 1, a powder inlet 2, a dispersion chamber 3, an agitator 4, an automatic valve 5, a drying chamber 6, a first conveyor belt 7, a second conveyor belt 8, a heating device 9, a heat insulating Plate 10 and powder outlet 11. The chassis 1 is connected to the drying chamber 6, the dispersion chamber 3 is located directly above the drying chamber 6, the automatic valve 5 is located below the agitator 4, the first conveyor belt 7 is located above the second conveyor belt 8, and the heating The device 9 is installed on the left and right sides of the drying chamber 6 , and the powder outlet 11 is located below the left end of the second conveyor belt 8 .

[0015] The present invention is further provided that: the agitator 4 is installed horizontally in the dispersion chamber 3 .

[0016] The prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com