Light-controlled liquid drop movement method, light-controlled liquid drop movement micropipe and manufacturing method of light-operated liquid drop movement micropipe

A liquid droplet motion and microtube technology, applied in the direction of fluid flow, engine components, mechanical equipment, etc., can solve the problems of practical limitations, freedom of movement restrictions, and free control of droplets that cannot be batched, so as to improve practicality, Wide variety of effects with fast drive speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0084] Preparation Example 1 Preparation of microtubes for light-controlled droplet movement

[0085] 1. Prepare the wall material of the light-controlled droplet movement microtube:

[0086] The specific preparation method is as follows:

[0087] 1.1 Synthesis of epoxy cyclooctene:

[0088] Dissolve chloroperoxybenzoic acid in chloroform and add dropwise to the flask containing 1,5-cyclooctadiene. After the dropwise addition, stir at room temperature and filter to remove the white precipitate. Sodium bisulfate aqueous solution, sodium bicarbonate aqueous solution and sodium chloride aqueous solution are washed, and vacuum distillation obtains epoxy cyclooctene;

[0089] 1.2 Synthesis of 5-hydroxy-1-cyclooctene:

[0090]Add the anhydrous tetrahydrofuran solution of lithium aluminum hydride, dissolve the epoxidized cyclooctene in tetrahydrofuran, and add the anhydrous tetrahydrofuran solution dropwise under the protection of argon. Water terminates the reaction. The result...

Embodiment 1

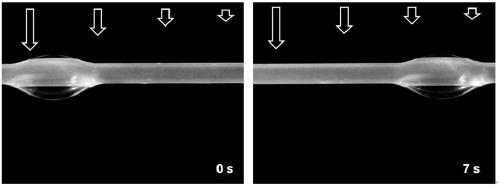

[0108] Example 1 Light-controlled droplet motion microtube drives droplet motion by changing the curvature of the outer wall

[0109] Both ends of the light-controlled liquid droplet movement microtube (with an inner diameter of 0.1 mm and an outer diameter of 0.11 mm) prepared in Preparation Example 1 were fixed. Use a micropipette to suspend 0.5 µL of silicone oil on the wall of the microtube. A light source is placed above the light-controlled droplet movement microtube, and an attenuation filter is placed between the light source and the light-control droplet movement microtube to generate attenuated light. Turn on the light source, the light source intensity is 100-120mW / cm -2 ;

[0110] Results: The outer wall of the microtubules produces asymmetric curvature changes, driving the droplet to move along the direction of light attenuation. The movement process is as follows: figure 1 shown.

Embodiment 2

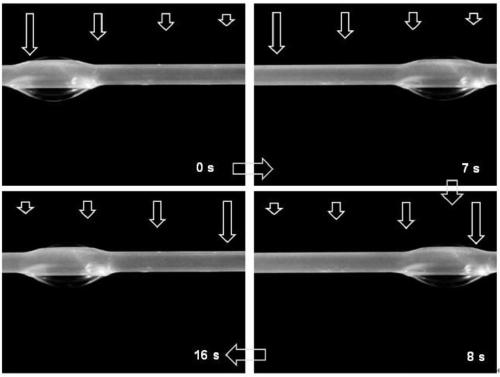

[0111] Example 2 Light-controlled droplet movement microtube controls the direction of droplet movement by changing the curvature of the outer wall

[0112] The experiment of Example 1 was repeated, except that when the capillary was irradiated with light, the placement direction of the attenuation sheet was changed, that is, the attenuation direction of light was adjusted.

[0113] It was found that the droplet on the wall of the microtubules changes the direction of movement, and the movement process is as follows: figure 2 As shown, see the movement process from 0 seconds to 7 seconds to 8 seconds to 16 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com