Modified anti-corrosion hydrotalcite, water-based intelligent anti-corrosion coating, preparation method and coating thereof

An anti-corrosion coating and hydrotalcite technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of poor anti-corrosion ability of water-based coatings, and achieve the effects of improving anti-corrosion ability, avoiding corrosion and improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

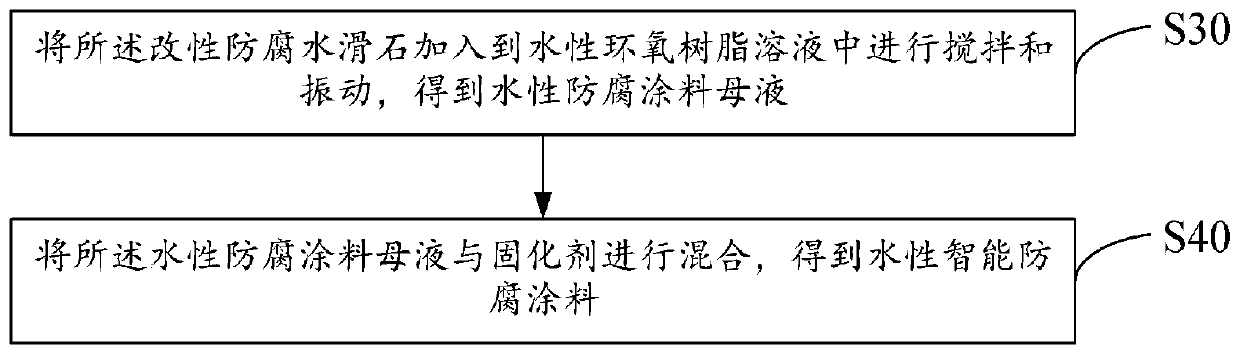

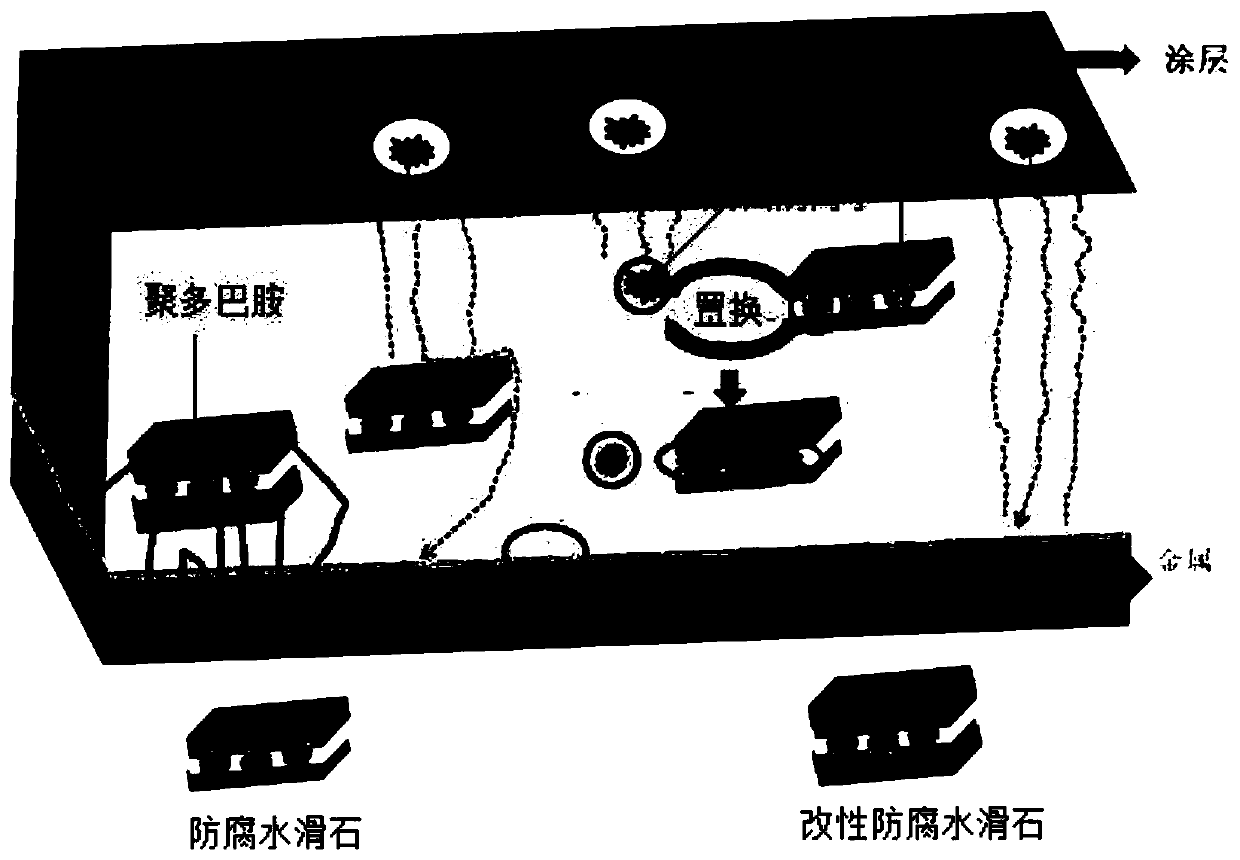

[0043] refer to figure 1 , the embodiment of the present invention provides a preparation method of modified anti-corrosion hydrotalcite, specifically comprising:

[0044] Step S10: drop the mixed solution of metal nitrate solution, sodium hydroxide and sodium tripolyphosphate into deionized water, stir and centrifuge to obtain anti-corrosion hydrotalcite.

[0045] Layered double hydroxide (Layered Double Hydroxide, LDH) is a general term for hydrotalcite (HT) and hydrotalcite-like compounds (Hydrotalcite-Like Compounds, HTLCs), a series of supramolecular materials assembled by intercalation of these compounds It is called hydrotalcite intercalation material (Layered DoubleHydroxides, LDHs). LDHs have a unique layered structure and are excellent anion exchange materials composed of positively and negatively charged mixed metal hydroxide layers with high metal dispersion. LDHs, especially heat-activated LDHs, are excellent anticorrosion materials because of their positively c...

Embodiment 1

[0084] (1) Preparation of anti-corrosion hydrotalcite: Boil deionized water and cool to 25°C. In parts by weight, 10 parts of Mg(NO 3 ) 2 ·6H 2 O and 5 parts Al(NO 3 ) 3 9H 2 O was dissolved in 50 parts of deionized water to form a metal nitrate solution at room temperature and an inert atmosphere. The content ratio of magnesium and aluminum in the metal nitrate solution was Mg:Al=2:1. At room temperature under an inert atmosphere, mix 3 parts of NaOH and 5 parts of Na 5 P 3 o 10 Dissolve in 50 parts of deionized water to make a mixed solution of sodium hydroxide and sodium tripolyphosphate. Then, the mixed solution of metal nitrate solution, sodium hydroxide and sodium tripolyphosphate was added dropwise into a beaker containing 100 parts of deionized water at the same time until the pH value of the final mixture was adjusted to 9.5 to obtain an alkaline mixture. The alkaline mixture was stirred at 350 rpm and 75°C for 8 hours to obtain a white paste, which was trans...

Embodiment 2

[0088] (1) Preparation of anti-corrosion hydrotalcite: Boil deionized water and cool to 25°C. In parts by weight, 10 parts of Mg(NO 3 ) 2 ·6H 2 O and 5 parts Al(NO 3 ) 3 9H 2 O was dissolved in 80 parts of deionized water to form a metal nitrate solution at room temperature and an inert atmosphere. The content ratio of magnesium and aluminum in the metal nitrate solution was Mg:Al=2:1. At room temperature under an inert atmosphere, mix 3 parts of NaOH and 5 parts of Na 5 P 3 o 10 Dissolve in 80 parts of deionized water to make a mixed solution of sodium hydroxide and sodium tripolyphosphate. Then, the mixed solution of metal nitrate solution, sodium hydroxide and sodium tripolyphosphate was added dropwise into a beaker containing 120 parts of deionized water at the same time until the pH value of the final mixture was adjusted to 9.5 to obtain an alkaline mixture. The alkaline mixture was stirred at 350 rpm and 75° C. for 8 hours to obtain a white paste, which was tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com