Preparation method of polysulfone resin material with low cyclic dimer content

A technology of cyclic dimer and resin material, applied in the field of preparation of polysulfone resin material, can solve the problems of lack of elasticity, brittle membrane filament, clogging of the filter head of spinning equipment, etc., and achieves low production cost, stable performance, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

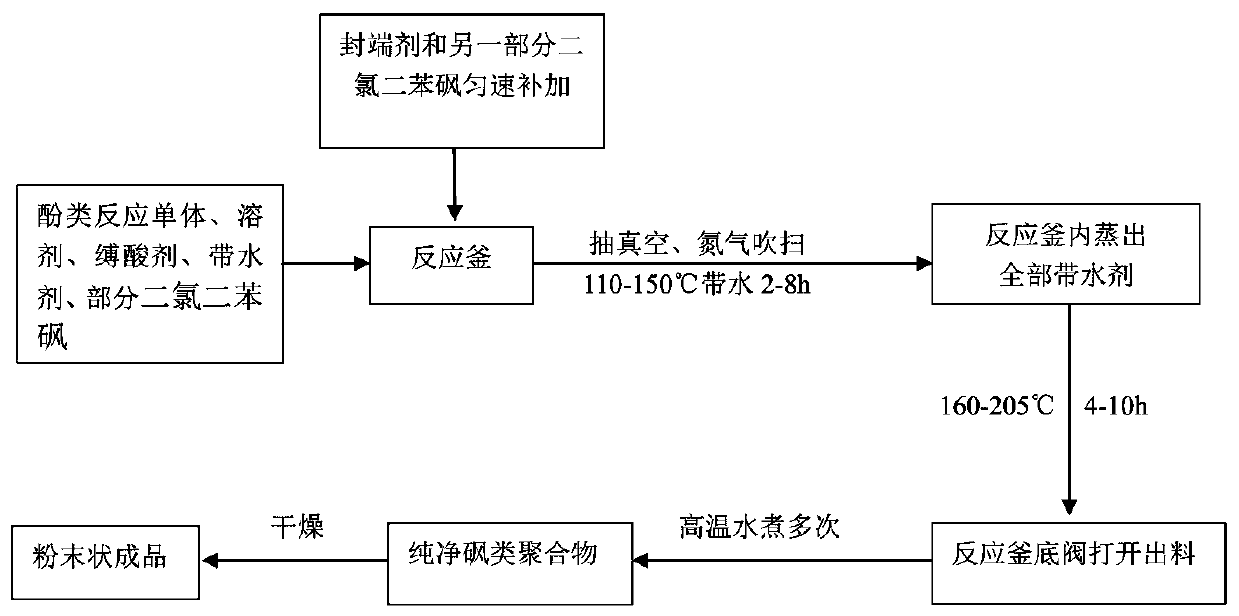

Method used

Image

Examples

Embodiment 1

[0036] Add 4.3kg of 4,4'-dichlorodiphenylsulfone, 6.6kg of bisphenol A, 5.2kg of potassium carbonate, 35kg of solvent N,N-dimethylacetamide (DMAC), and 15kg of xylene into a 100L polymerization reactor. After evacuating the kettle to ≤-0.08MPa, feed nitrogen to make the pressure in the kettle reach ≥0.00MPa. After nitrogen replacement three times, feed nitrogen to normal pressure reaction. The whole polymerization reaction is carried out under nitrogen protection, with water at 150°C for 2 hours, during which the The total mass of end-capping agent bisphenol S and p-cresol is 42g (the mass ratio of the two is 1:1) and 4.6kg of 4,4'-dichlorodiphenyl sulfone are dissolved in 35kg of N,N-dimethyl ethyl In the amide, add it into the reaction kettle at a uniform speed.

[0037] After all the xylene was evaporated, the temperature was raised to 162°C, and the polymerization was continued for 10h. The solid content rate is maintained at 22-30%, and the reaction ends when the viscosi...

Embodiment 2

[0042] Add 35kg of sulfolane, 7.2kg of bisphenol S, 6kg of potassium bicarbonate, 4.1kg of 4,4'-dichlorodiphenylsulfone, and 20kg of xylene into a 100L polymerization reactor. After evacuating the kettle to ≤-0.08MPa, feed nitrogen to make the pressure in the kettle reach ≥0.00MPa. After nitrogen replacement three times, feed nitrogen to normal pressure reaction. The whole polymerization reaction is carried out under nitrogen protection, with water at 155°C for 6 hours, during which the Compound 37g of end-capping agent p-ethylphenol and p-cresol (the mass ratio of the two is 2:3) and 4.8kg of 4,4'-dichlorodiphenyl sulfone are dissolved in 25kg of sulfolane and added to the reactor at a uniform speed Inside.

[0043] After the addition of water, all the xylene was distilled off, then the temperature was raised to 200°C, the polymerization was continued for 4 hours, and the reaction was terminated when the viscosity reached 8000 centipoise.

[0044] When the polyethersulfone p...

Embodiment 3

[0048] Add 30kg of dimethyl sulfoxide (DMSO), 5.3kg of biphenol, 5.8kg of potassium carbonate, 4.5kg of 4,4'-dichlorodiphenyl sulfone, and 20kg of xylene into a 100L polymerization reactor. After evacuating the kettle to ≤-0.08MPa, feed nitrogen to make the pressure in the kettle reach ≥0.00MPa. After nitrogen replacement three times, feed nitrogen to normal pressure reaction. The whole polymerization reaction is carried out under nitrogen protection, with water at 155°C for 5 hours. Compound 36g of end-capping agent bisphenol Z and phenol (the mass ratio of the two is 3:7) and 4.4kg of 4,4'-dichlorodiphenyl sulfone dissolved in 30kg of dimethyl sulfoxide and added to the reaction at a uniform speed Inside the cauldron.

[0049] After the addition of water, all the xylene was evaporated, and then the temperature was raised to 180°C, and the polymerization was continued for 8 hours, and the polymerization reaction was terminated when the viscosity reached 11,000 centipoise.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com