Environmentally-friendly concrete for inducing adhesion of marine adhesive organisms, and preparation method thereof

A technology for sessile organisms and concrete, which is applied to clay preparation devices, chemical instruments and methods, animal husbandry, etc., can solve the problems of poor concrete durability, low oyster larvae attachment efficiency, and large dosage, and achieves strong oyster larvae attachment ability. , Solve the problem of mildew, the effect of small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

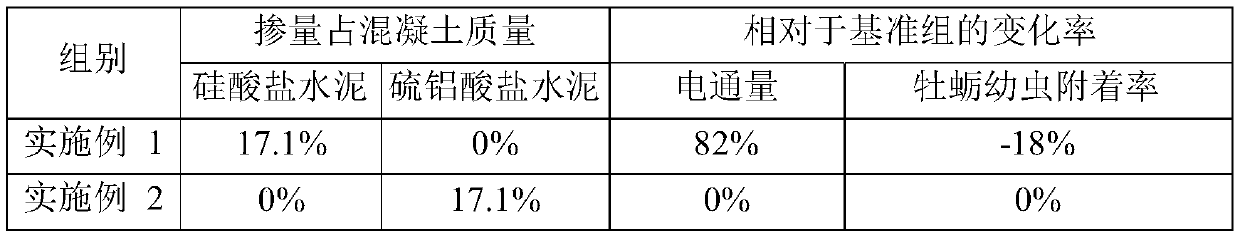

[0042] Example 1: The proportion of ordinary Portland cement concrete, the weight ratio of ordinary Portland cement, gravel, sand, water and polycarboxylate superplasticizer powder is: 17.1%, 46.67%, 29.0%, 7.2% , 0.03%.

[0043] The parent rock of the crushed stone is one of basalt and diabase, and its maximum particle size is no more than 50mm, and the gradation is good; the sand is river sand and machine-made sand (the parent rock is granite, basalt, one) or one or several types of desalinated sea sand with good gradation. The water mentioned should meet the concrete water standard (JGJ63-2006), Cl - Content4.5, little effect on cement initial setting time difference and final setting time, strength and permeability. And the above materials selected in Examples 1-18 are the same.

Embodiment 2

[0044] Embodiment 2: benchmark concrete proportioning, the proportioning by weight of sulphoaluminate cement, crushed stone, sand, water and polycarboxylate superplasticizer powder is successively: 17.1%, 46.67%, 29.0%, 7.2%, 0.03%.

[0045]

[0046] By comparing the above implementations, it can be seen that under the same dosage, the electric flux of sulphoaluminate cement concrete is smaller, indicating that the concrete has good impermeability, and compared with ordinary silicate, its oyster larvae are less likely to adhere to rate increased significantly.

Embodiment 3

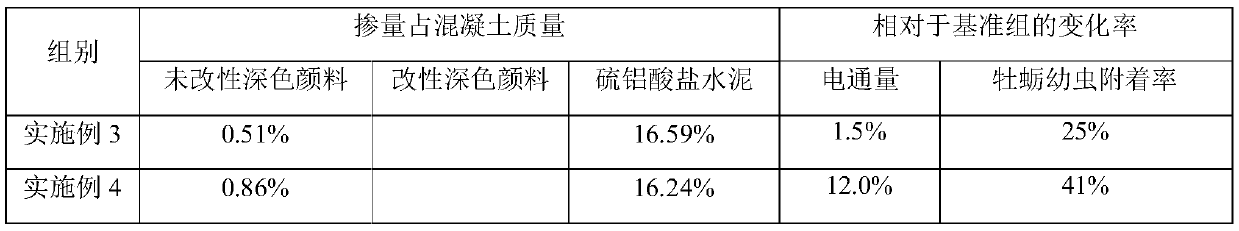

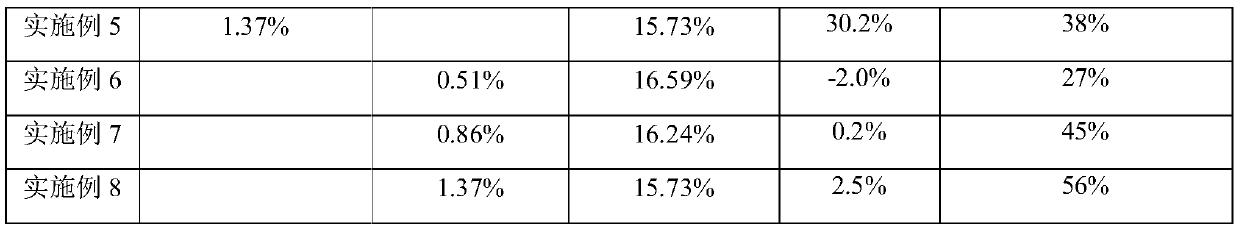

[0047] Example 3: The weight proportions of unmodified dark pigment, sulphoaluminate cement, gravel, sand, water and polycarboxylate water reducer powder are: 0.51%, 16.59%, 46.67%, 29.0%, 7.2% %, 0.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com