Method for recycling waste liquid generated by absorbing HCl and application of method

A waste liquid and water absorption technology, applied in chemical instruments and methods, ammonia preparation/separation, inorganic chemistry, etc., can solve the problems of ineffective utilization, environmental pollution, high cost of dilute hydrochloric acid and waste lye treatment, and achieve saving Waste disposal costs and production and operation costs, avoiding energy consumption and transshipment costs, and the effect of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

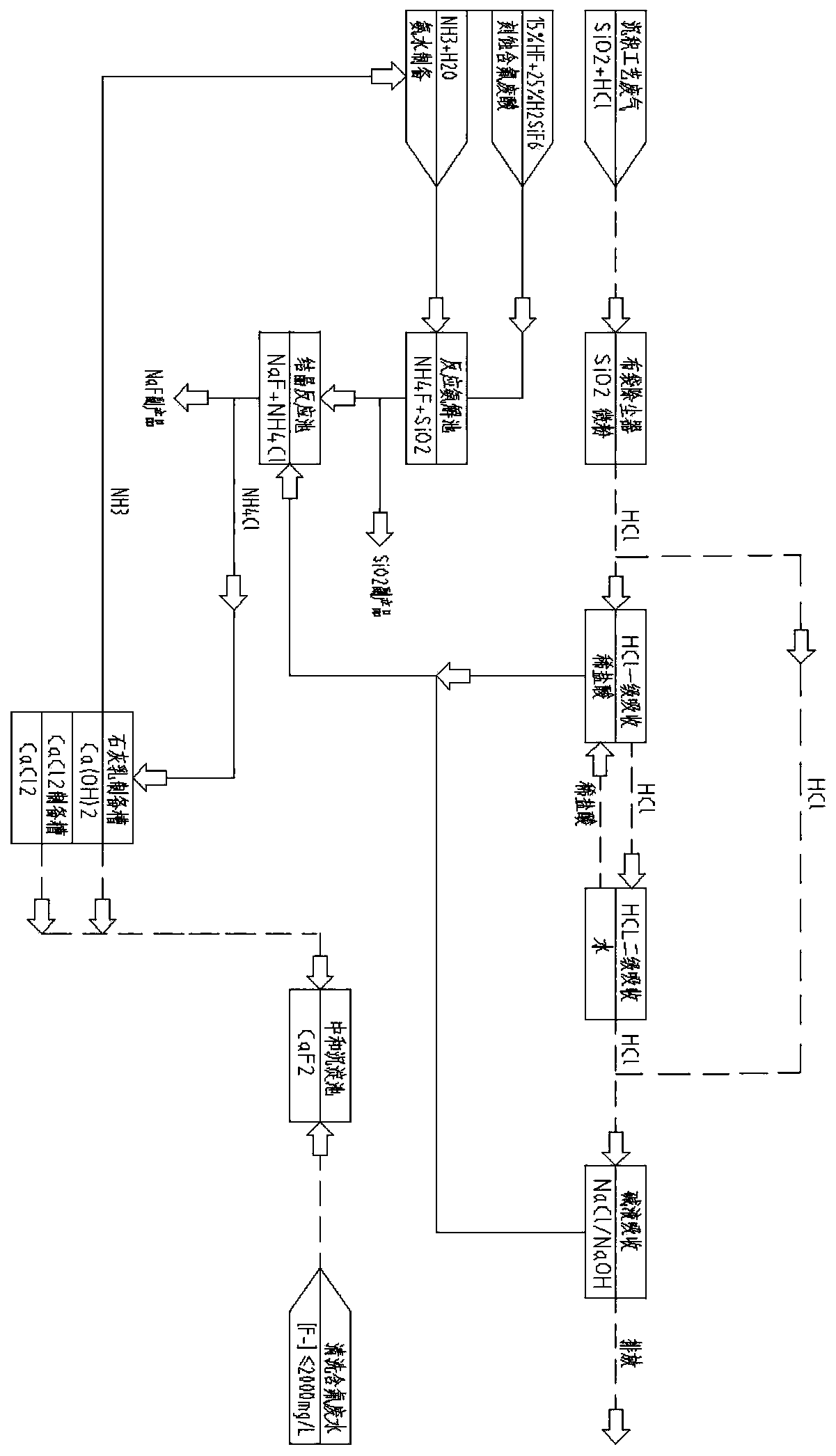

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] The invention provides a method for reusing the waste liquid produced by absorbing HCl, comprising the following steps:

[0035] (1) Add excess ammonia water, HF, H 2 SiF 6 and NH 3 ·H 2 O reacts to form NH 4 F and SiO 2 ;

[0036](2) filter the reaction product of step (1) to obtain the filtrate, which is mixed with the waste liquid produced by absorbing HCl, NH 4 F reacts with NaCl to form NaF and NH 4 Cl.

[0037] In the reuse method of the waste liquid produced by absorbing HCl of the present invention, the dilute hydrochloric acid and waste lye produced by absorbing HCl, which have low utilization value or even cannot be reused, are reused after mixing, and SiO can also be generated. 2 and NaF can not only be exported as a by-product, but also due to the SiO 2 As a solid substance, NaF has a low solubility and can be precipitated by crystallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com