Exhausting silencing apparatus for air-tight rotary compressor

A technology of rotary compressor and muffler, applied in muffler, rotary piston machine, rotary piston pump, etc., can solve the problems of complex structure and manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

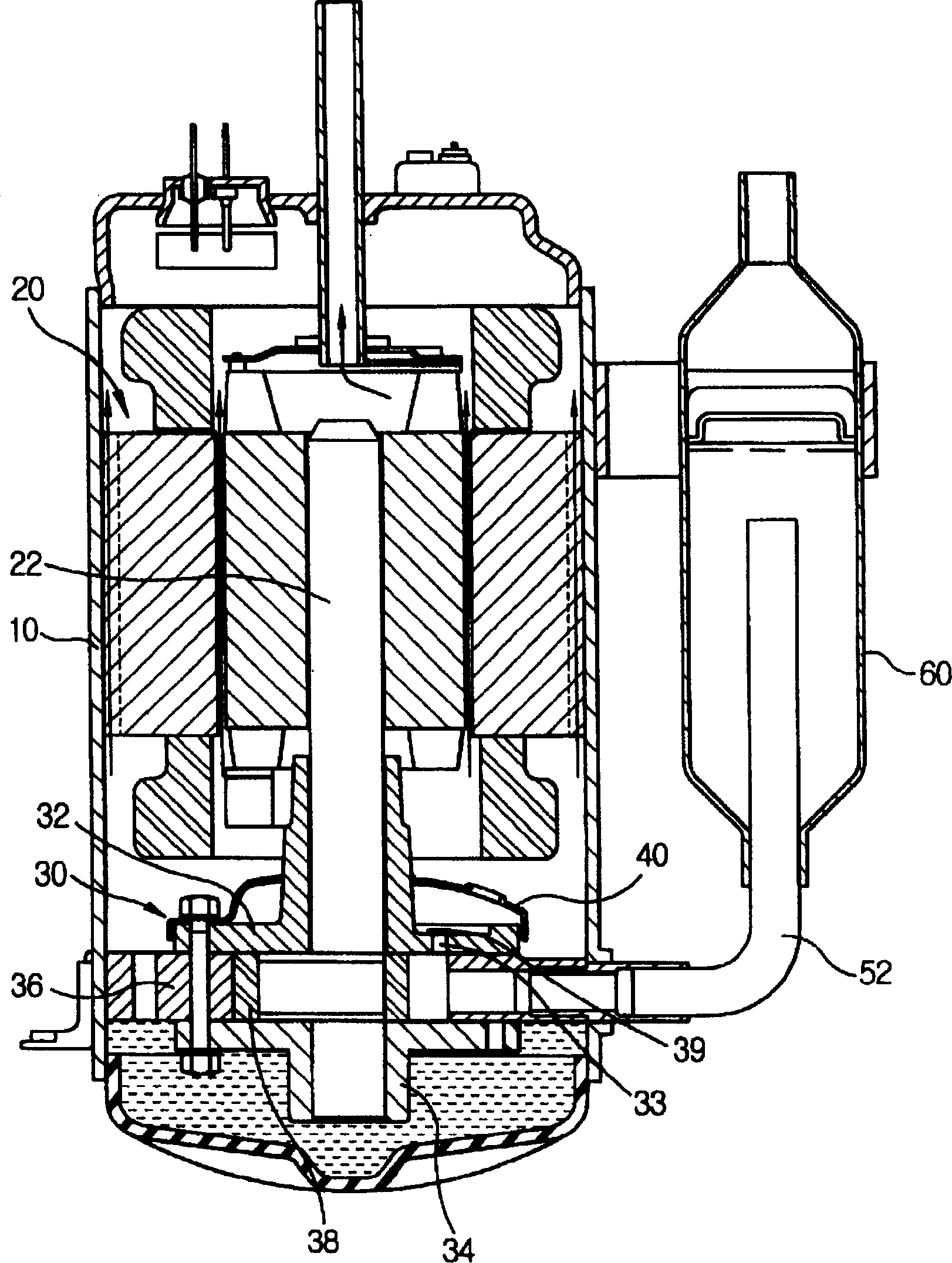

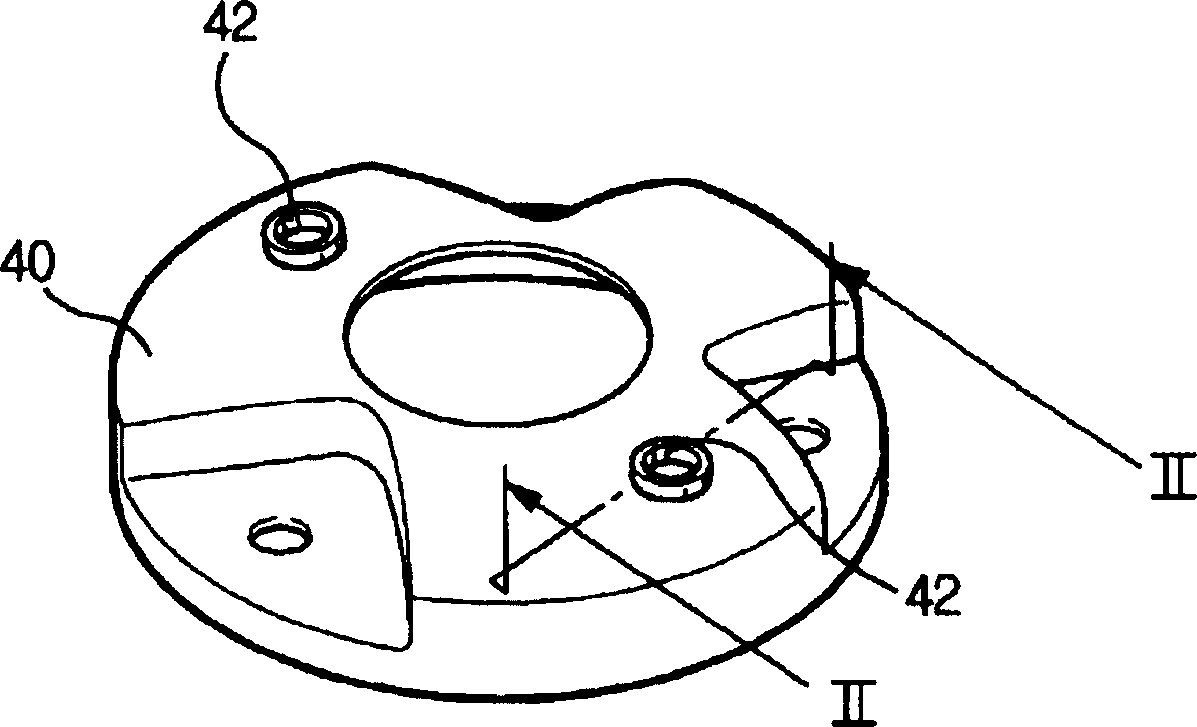

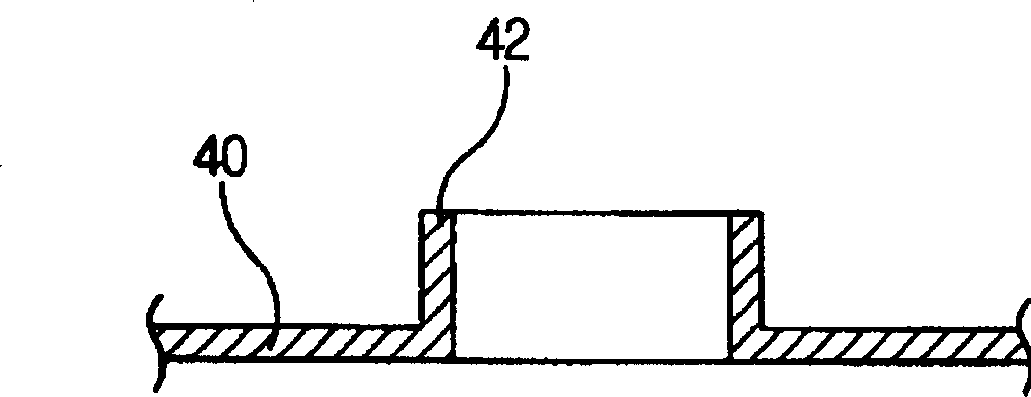

[0027] Figure 6 The discharge muffler device of the airtight rotary compressor according to the preferred embodiment of the present invention is shown. Figure 7 Is along Figure 6 The cross-sectional view of line V-V shows the main part of the phase changing device in detail, which is the main aspect of the present invention. In the drawings, the reference numeral 110 denotes the main body of the silencer, and the reference numeral 120 denotes the phase changing device.

[0028] As shown in the figure, the muffler main body 110 includes a skirt 112 which extends downwardly along the circumference of the muffler main body 110. Such as figure 1 As shown, the muffler main body 110 is disposed above the upper flange 32 where the discharge port 33 is opened. Therefore, a noise reduction space is formed between the main body 110 and the upper flange 32. In addition, a pair of discharge openings 114 are opened on the main body of the noise reduction device for discharging the refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com