Bamboo tableware processing forming method and device

A technology for processing and forming tableware, which is applied in the field of processing and forming methods and devices for bamboo tableware, can solve the problems of low processing efficiency and easy generation of burrs on the edges of bamboo chips, and achieve the effects of simple structure, improving processing and forming efficiency, and preventing random splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

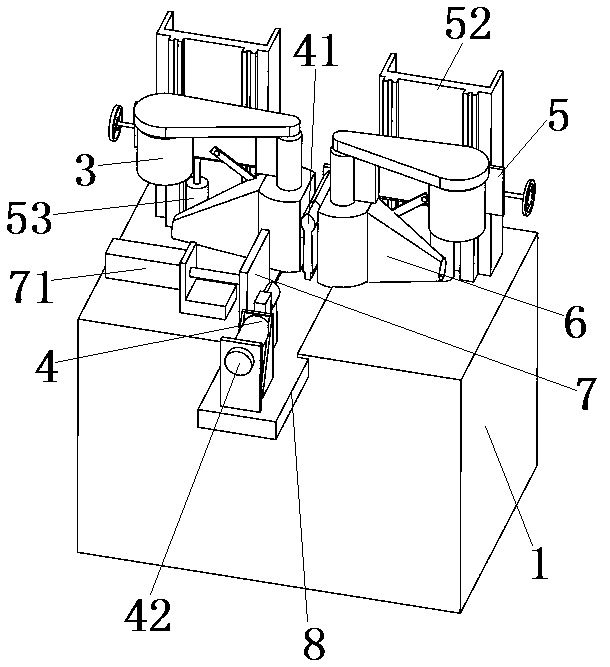

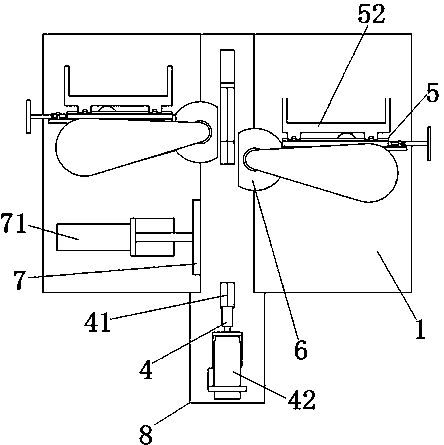

[0059] refer to Figure 1~3 , a bamboo tableware processing device, comprising a processing platform 1, a milling cutter 2, a motor 3 for controlling the rotation of the milling cutter 2, and a clamping member 4 for clamping a plurality of bamboo slices. The contour of the milling cutter 2 when it rotates matches the contour of at least one side of the bamboo tableware.

[0060] In this embodiment, at least one movement of the clamping part 4 and the milling cutter 2 is set on the processing platform 1 to ensure that there is a feed movement between the bamboo chip and the milling cutter 2. In this embodiment, the preferred clamping part 4 moves set up . For example: the processing platform 1 is provided with at least one electric slide rail, and the clamping part 4 is arranged on the slider of the electric slide rail; or, the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com