Automatic rotating mechanism for chemical metal cylinder

An automatic rotation and metal cylinder technology, which is applied to metal processing equipment, manufacturing tools, grinding racks, etc., can solve the problems of laborious manual rotation and large metal cylinders, and achieve the effect of reducing the amount of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

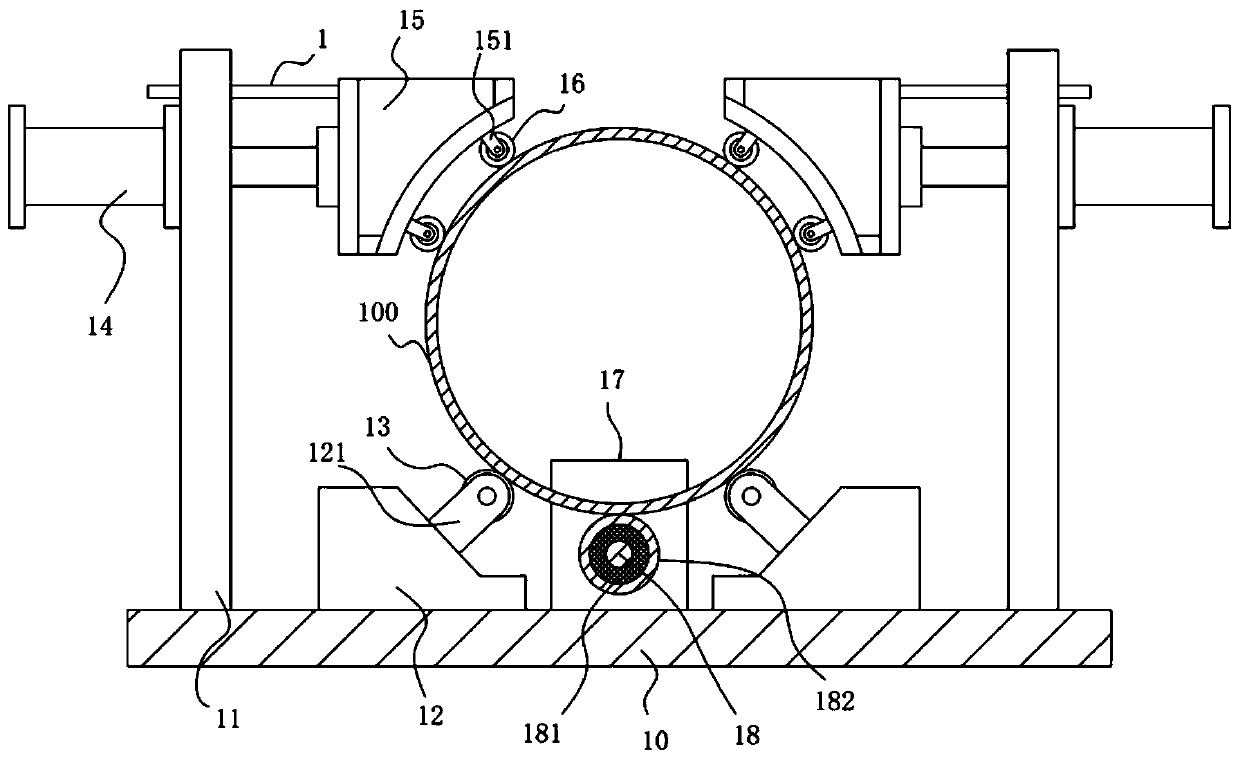

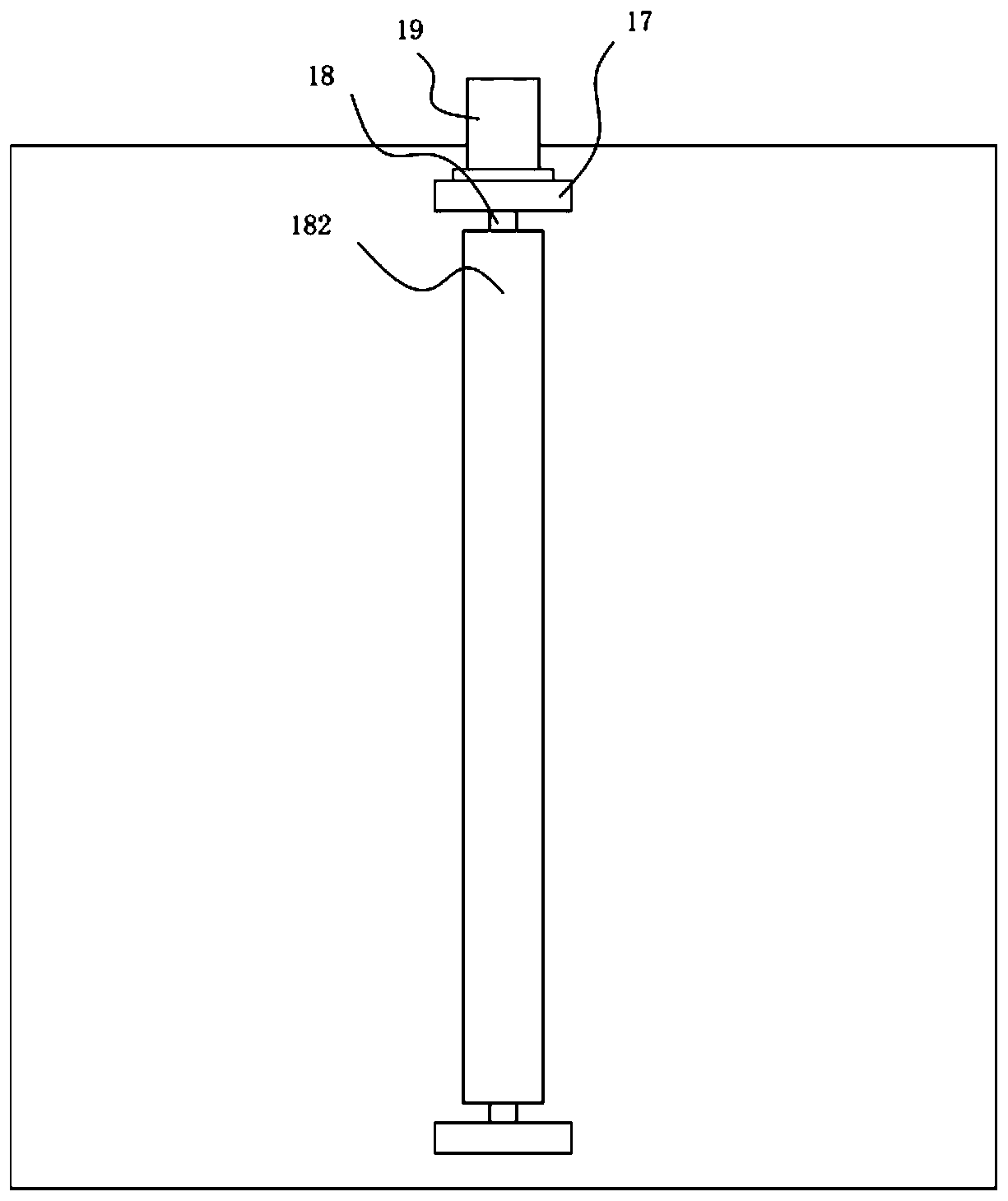

[0016] Example: see Figure 1 to Figure 2 Shown, a kind of chemical industry metal drum automatic rotation mechanism comprises a bottom plate 10, the left and right sides of the top surface of the bottom plate 10 are fixed with side support plates 11, the top surface of the bottom plate 10 between the two side support plates 11 is fixed There are two lower support blocks 12, the inner side walls of the two lower support blocks 12 are inclined wall plates, and the bottom roller body 13 is hinged on the inclined wall plates, and the two sides of the bottom surface of the cylinder body 100 to be processed are pressed against the corresponding two sides. On the bottom roller body 13;

[0017] A compression oil cylinder 14 is fixed on the outer side wall of the two side support plates 11, and the push rod of the compression oil cylinder 14 passes through the inner side wall of the side support plate 11 and is fixed with a compression seat 15, and the two compression seats 15 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com