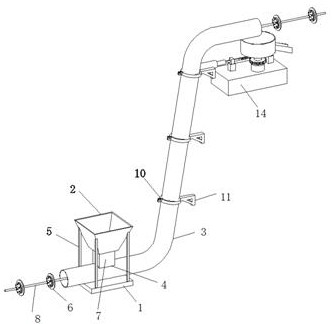

Wheat lifting equipment for flour processing

A wheat and flour technology, applied in conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of limited application scope of equipment, lifting angle can only be within a certain range, inconvenient adjustment, etc., to achieve flexible installation and use , Wide application range and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

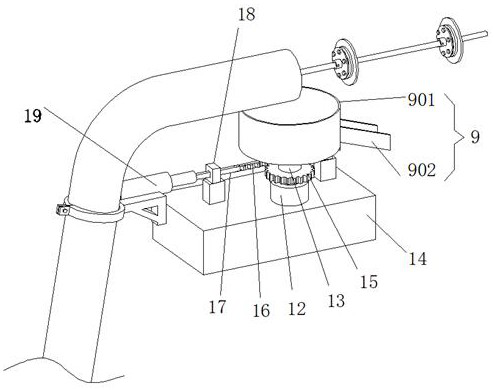

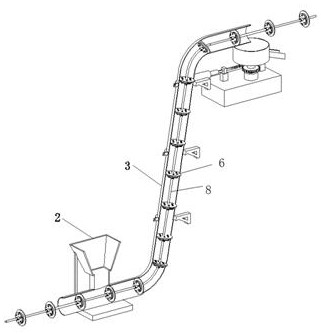

[0041] Embodiment 2 is implemented on the basis of 1, such as Figure 9 As shown, the outer walls of the two semi-circular sleeves 604 are respectively fixed with cleaning plates 605 , and the outer walls of the cleaning plates 605 are equipped with cleaning brushes 606 .

[0042] In the specific application of this embodiment, 3 to 5 lifting plate assemblies 6 can be spaced apart and cleaning plates 605 are respectively fixed on the outer walls of the two semicircular sleeves 604. The inner wall of the transmission pipe 3 is in contact with each other, so that when the hoisting motor 22 works to drive the endless transmission chain to rotate, the cleaning brush 606 can clean the dust and impurities on the inner wall of the transmission pipe 3, which is beneficial to ensure the cleanliness of the inner wall of the transmission pipe 3 on the one hand, and on the other hand The unimpeded operation of the lifting plate assembly 6 is guaranteed.

[0043] Combining Embodiment 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com