Maintenance crane and rail type container portal crane

A lifting device and connecting device technology, which is applied in the direction of cranes, trolley cranes, hoisting devices, etc., can solve the problems of maintenance work, installation failure, and trolley running mechanism prone to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

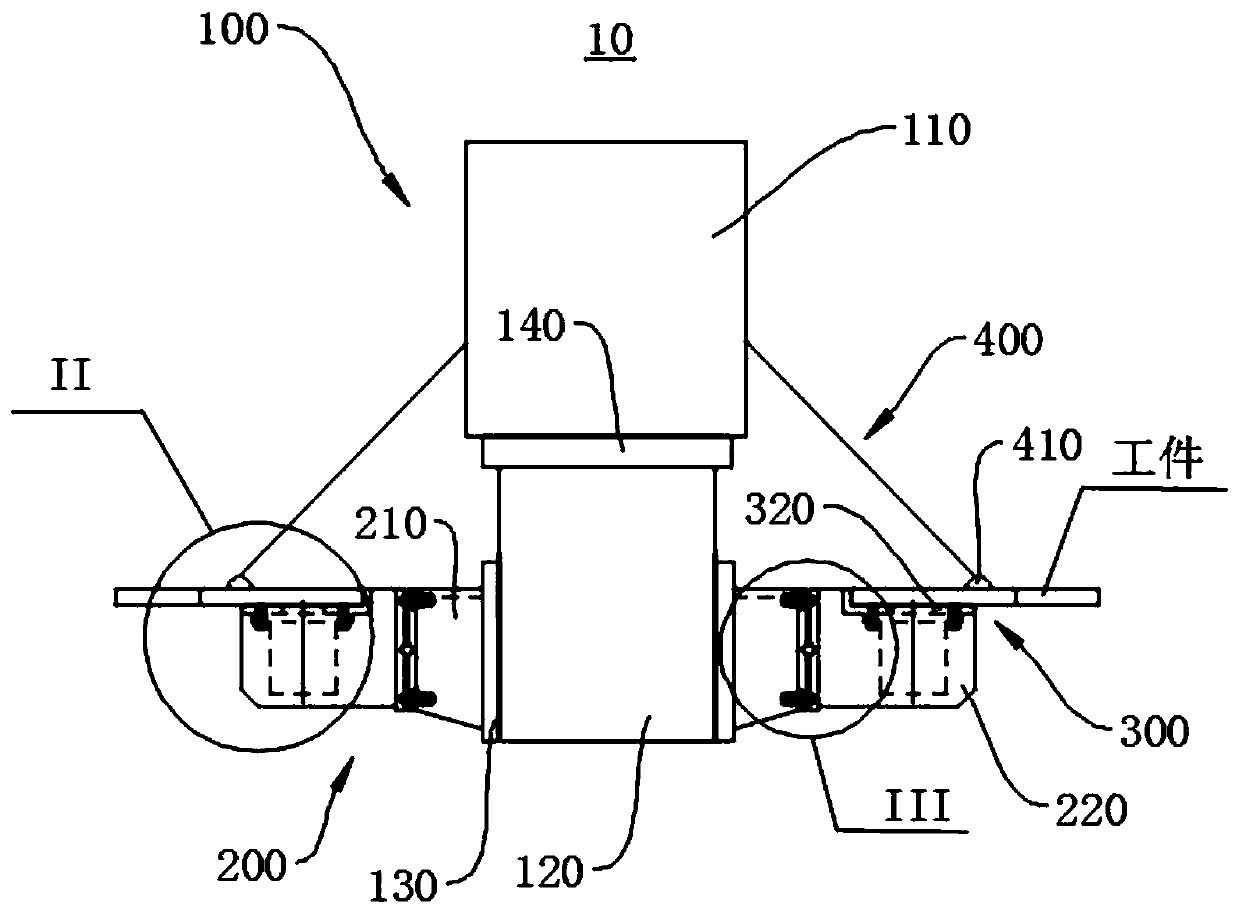

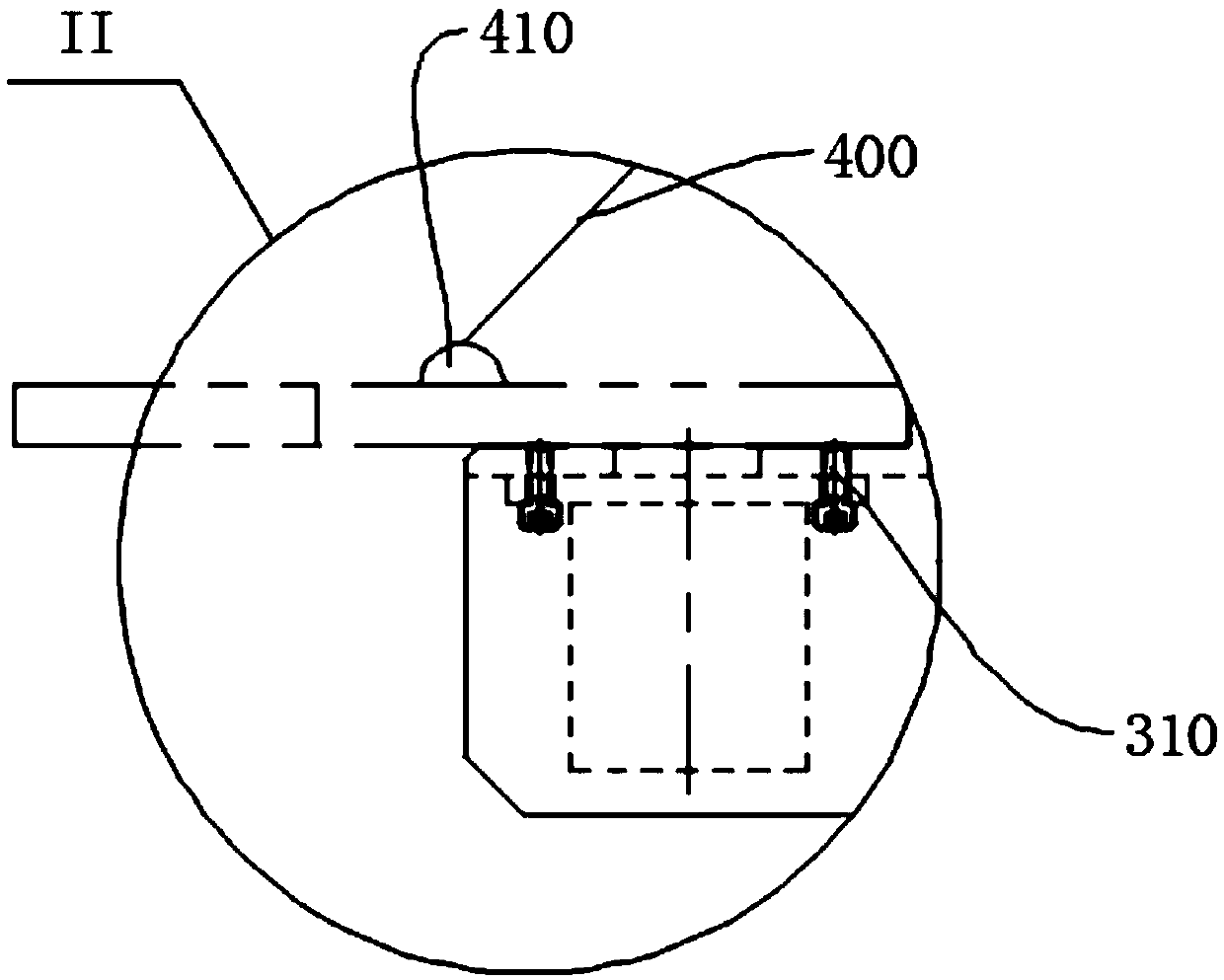

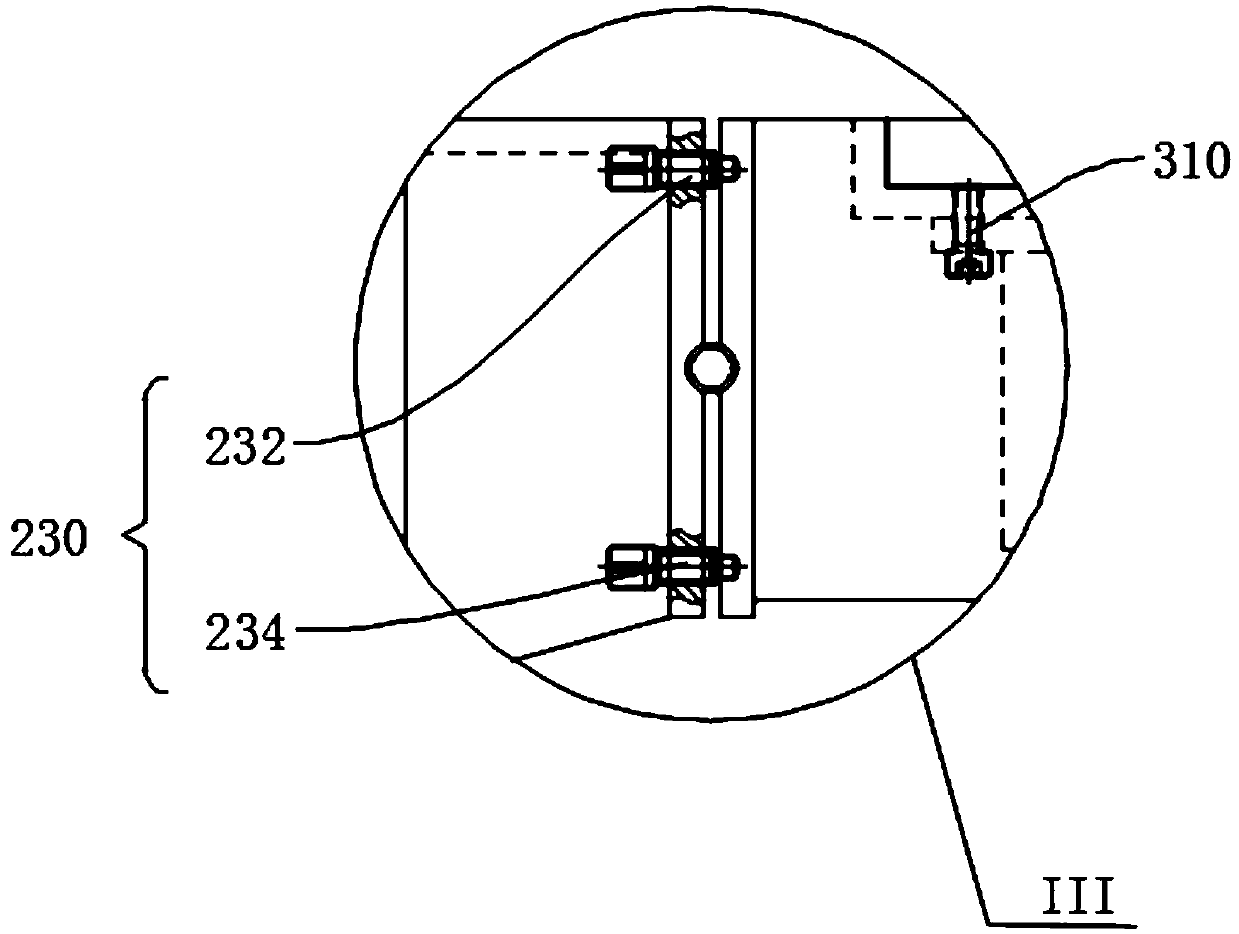

[0040] Please refer to Figure 1 to Figure 3 , the present embodiment provides a maintenance crane 10, which includes a lifting device 100, the lifting device 100 includes a lifting push rod 110 and a connecting piece 120 arranged at the end of the lifting push rod 110; the connecting device for connecting workpieces 200, the connecting device 200 includes a first adjusting member 210 and a second adjusting member 220, the first adjusting member 210 is rotatably connected to the connecting member 120; the second adjusting member 220 is rotatably connected to The end of the first adjusting member 210 away from the connecting member 120 ; the end of the second adjusting member 220 away from the first adjusting member 210 is provided with a clamping portion 300 for clamping a workpiece.

[0041]In this embodiment, a driving device 130 is provided at the connection between the first adjusting member 210 and the connecting member 120 , and the driving device 130 is used to drive th...

Embodiment 2

[0054] Please refer to Figure 4 , this embodiment provides a rail-mounted container gantry crane 20, the rail-mounted container gantry crane 20 includes a liftable door frame 500 and the above-mentioned maintenance crane 10, and the liftable door frame 500 includes two The lifting frame 510 arranged laterally symmetrically is connected to the supporting beam 520 of the lifting frame 510 , and the end of the lifting push rod 110 away from the connecting member 120 is slidably connected to the supporting beam 520 .

[0055] Specifically, in this embodiment, the end of the lifting frame 510 away from the supporting beam 520 is provided with a traveling wheel 530 and a pedal brake (not shown in the figure). The traveling wheels 530 are provided to facilitate the operation of the maintenance crane 10 to a designated position, and the foot-operated brakes are provided to secure the track-mounted container gantry crane 20 after the maintenance crane 10 travels to a designated positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com