Non-noble metal isobutane dehydrogenation catalyst taking eggshell-shaped mesoporous material as carrier, preparation method and application thereof

A dehydrogenation catalyst and non-precious metal technology, applied in catalyst activation/preparation, physical/chemical process catalysts, hydrocarbons, etc., can solve the problems of high production cost, environmental pollution, etc., and achieve high selectivity and high alkane conversion rate , the effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] According to the present invention, in the step (a), the mixing and contacting conditions include: temperature 10-60° C., time 0.2-100 h, pH 1-6; the pH value can be formed by adding hydrochloric acid, for example. In order to be more conducive to the uniform mixing of various substances, according to a preferred embodiment of the present invention, the mixing and contacting is carried out under stirring conditions.

[0037]According to the present invention, in step (a), the solution condition may be an aqueous solution condition. Preferably, in order to facilitate the dissolving of the template agent, a buffer solution of acetic acid and sodium acetate with a pH value of 1-6 can be used to form a solution condition, and for example alcohol reagents (such as methanol, ethanol, n-propanol, etc.) , isopropanol, etc.).

[0038] Preferably, the amount weight ratio of the templating agent, the trimethylpentane and the tetramethoxysilane is 1:(1.2-20):(0.1-15); more prefera...

Embodiment 1

[0084] This example is used to illustrate the non-noble metal-based isobutane dehydrogenation catalyst and its preparation method.

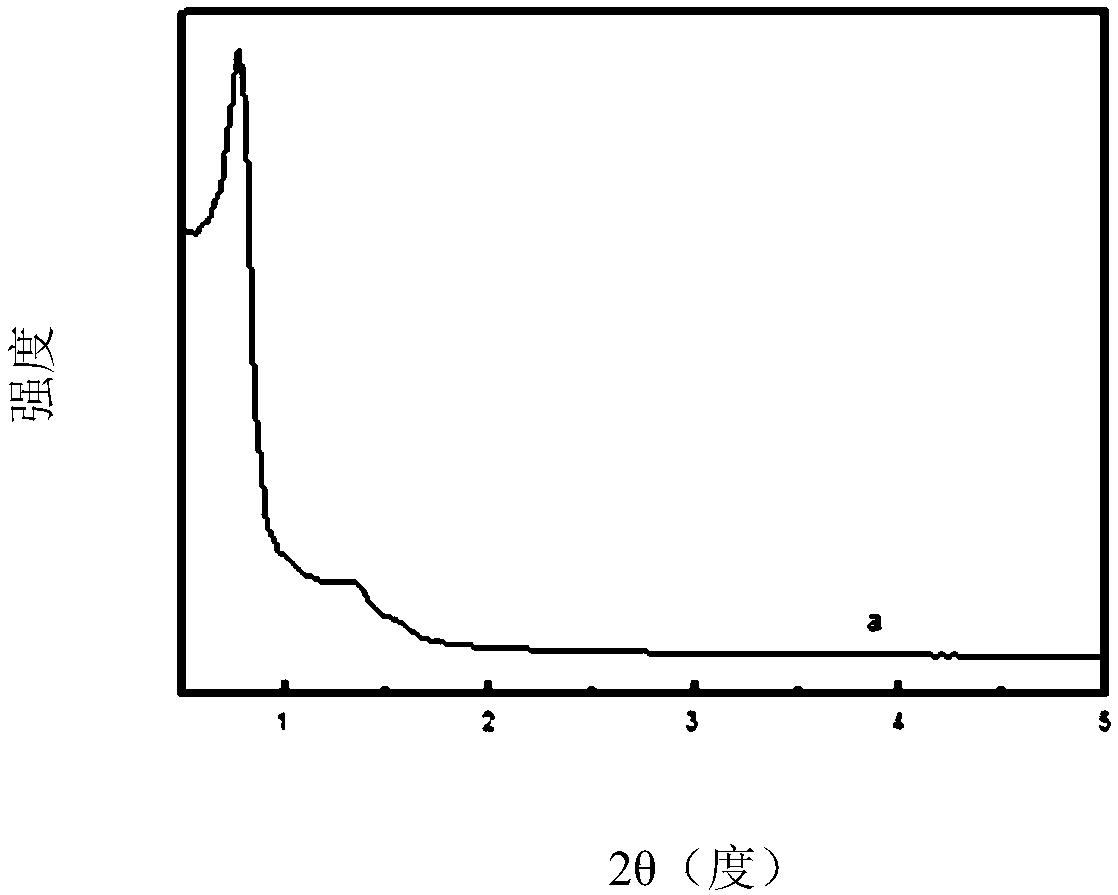

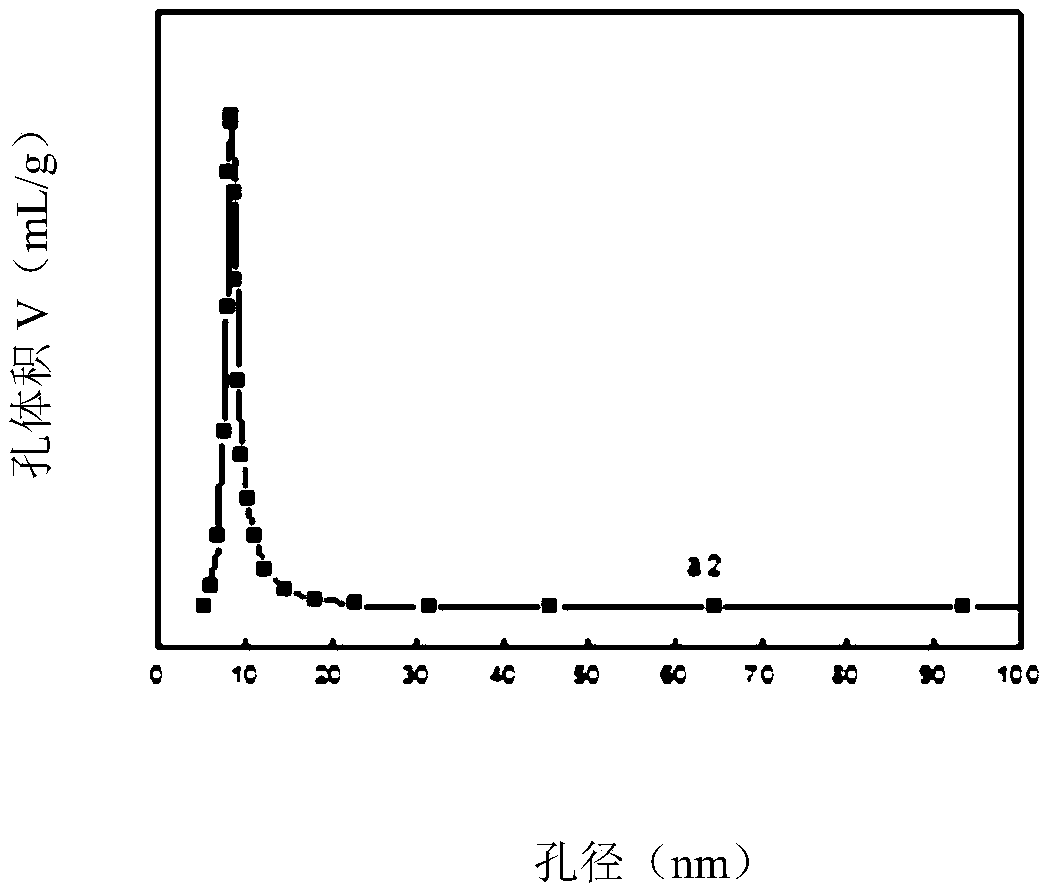

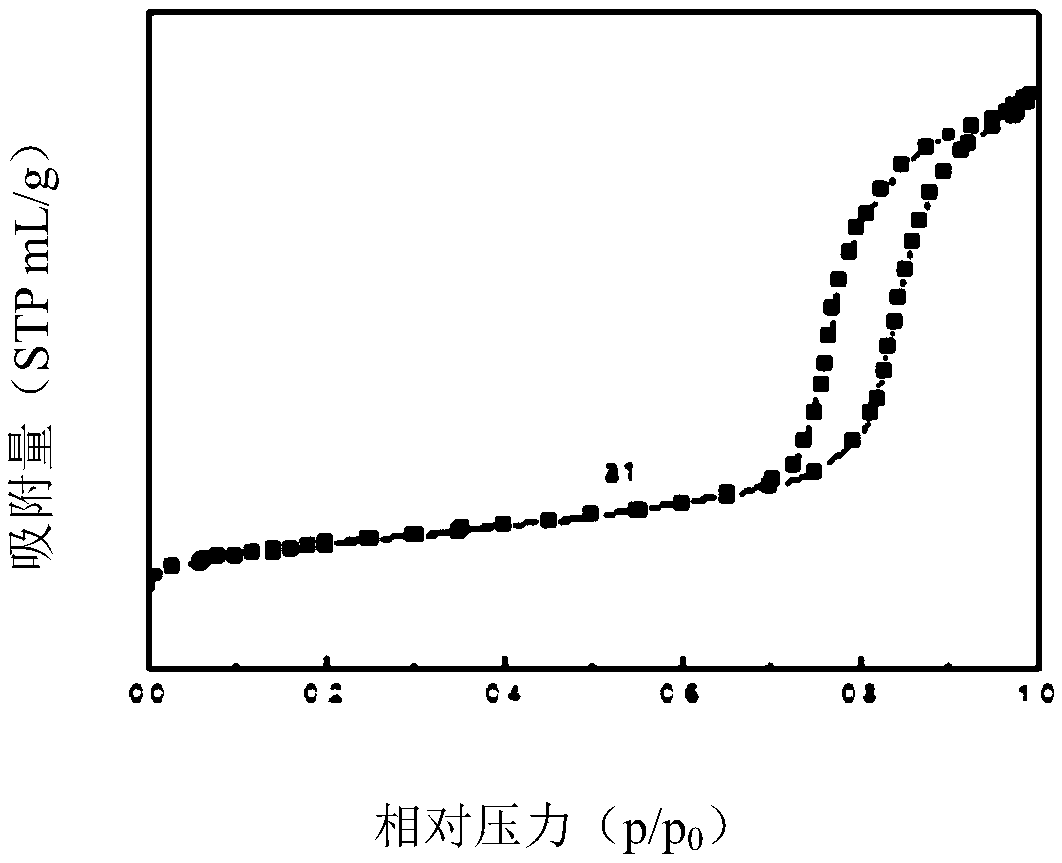

[0085] (1) Preparation of eggshell-like mesoporous material carrier

[0086] Add 1.0 g of three-stage copolymer polyethylene glycol-polyglycerol-polyethylene glycol P123 and 1.69 g of ethanol to 28 mL of a buffer solution of acetic acid and sodium acetate with a pH value of 4.4, and stir at 15 °C until poly Ethylene glycol-polyglycerol-polyethylene glycol P123 is completely dissolved; then 6g of trimethylpentane is added to the above solution, and after stirring for 8 hours at 15°C, 2.13 g of tetramethoxysilane is added to the above solution , after stirring at 15°C for 20h, the solution was transferred to a polytetrafluoroethylene-lined reactor, crystallized at 60°C for 24h, and then filtered, washed, and dried to obtain the raw eggshell-like mesoporous material powder. The eggshell-shaped mesoporous material raw powder was calcined in a muffle...

Embodiment 2

[0101] This example is used to illustrate the non-noble metal-based isobutane dehydrogenation catalyst and its preparation method.

[0102] (1) Preparation of eggshell-like mesoporous material carrier

[0103] Add 1.0 g of three-stage copolymer polyethylene glycol-polyglycerol-polyethylene glycol P123 and 1.84 g of ethanol to 28 mL of a buffer solution of acetic acid and sodium acetate with a pH value of 5, and stir at 40 °C until poly Ethylene glycol-polyglycerol-polyethylene glycol is completely dissolved; then 9.12g of trimethylpentane is added to the above solution, and after stirring at 40°C for 6h, 3.04g of tetramethoxysilane is added to the above solution , after stirring at 40°C for 15h, the solution was transferred to a polytetrafluoroethylene-lined reactor, crystallized at 100°C for 10h, and then filtered, washed, and dried to obtain the raw eggshell-like mesoporous material powder. The eggshell-shaped mesoporous material raw powder was calcined in a muffle furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com