Non-noble metal isobutane dehydrogenation catalyst taking hexagonal mesoporous material as carrier, preparation method and application thereof

A dehydrogenation catalyst and non-precious metal technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, heterogeneous catalyst chemical elements, etc., can solve the problems of high preparation cost and environmental pollution, Achieve the effects of high selectivity, high alkane conversion rate and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] The present invention has no special limitation on the conditions of the mixing and contacting, for example, the conditions of the mixing and contacting may include: a temperature of 25-60° C., a time of 10-240 min, and a pH value of 1-7. In order to be more conducive to the uniform mixing of various substances, according to a preferred embodiment of the present invention, the mixing and contacting is carried out under stirring conditions.

[0042] According to a preferred embodiment of the present invention, the process of mixing and contacting the template agent, potassium sulfate, acid agent and orthosilicate comprises: mixing the template agent triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene F108 Added to the aqueous solution of hydrochloric acid, according to the molar feed ratio, triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene F108:potassium sulfate:water:hydrogen chloride=1:200-400:10000-30000:100-900 , stirred at a tempera...

Embodiment 1

[0084] This example is used to illustrate the non-noble metal-based isobutane dehydrogenation catalyst and its preparation method.

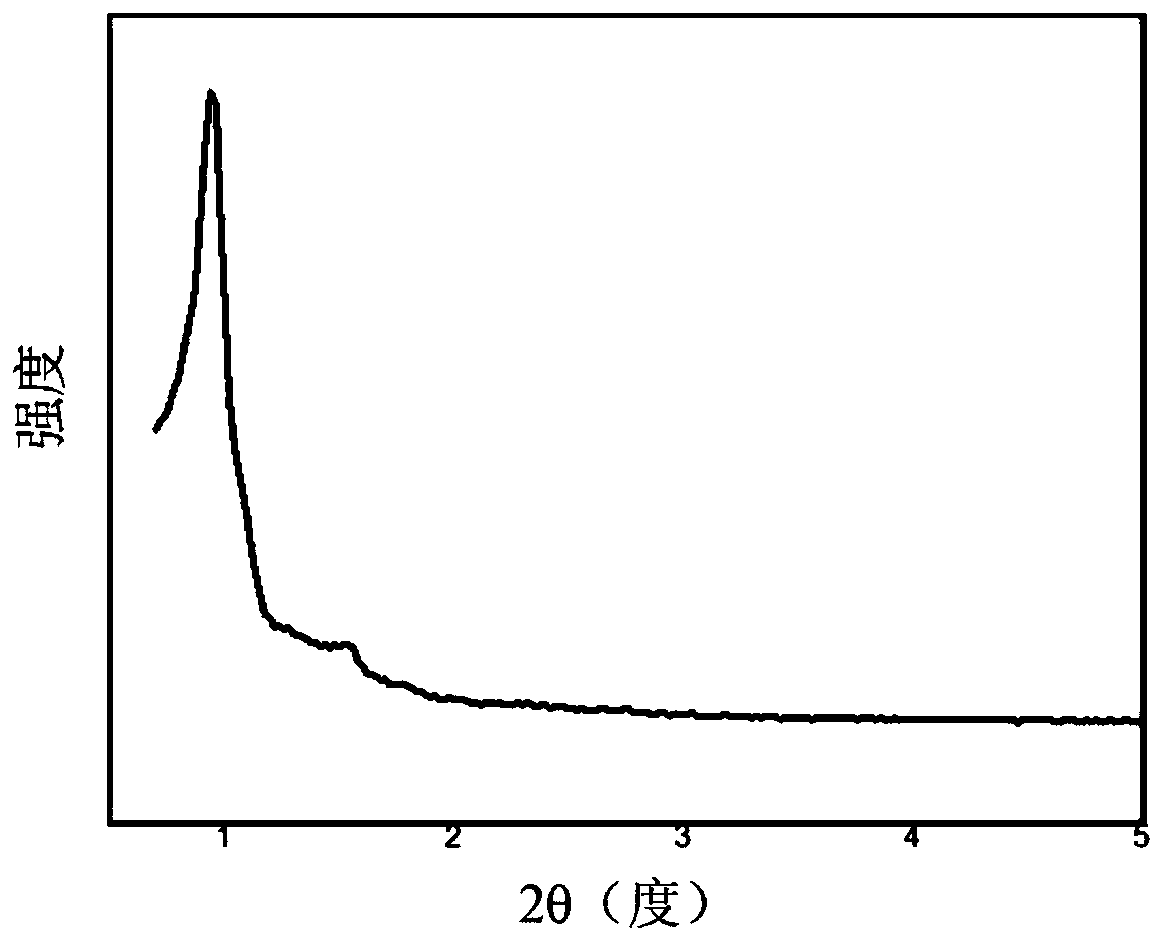

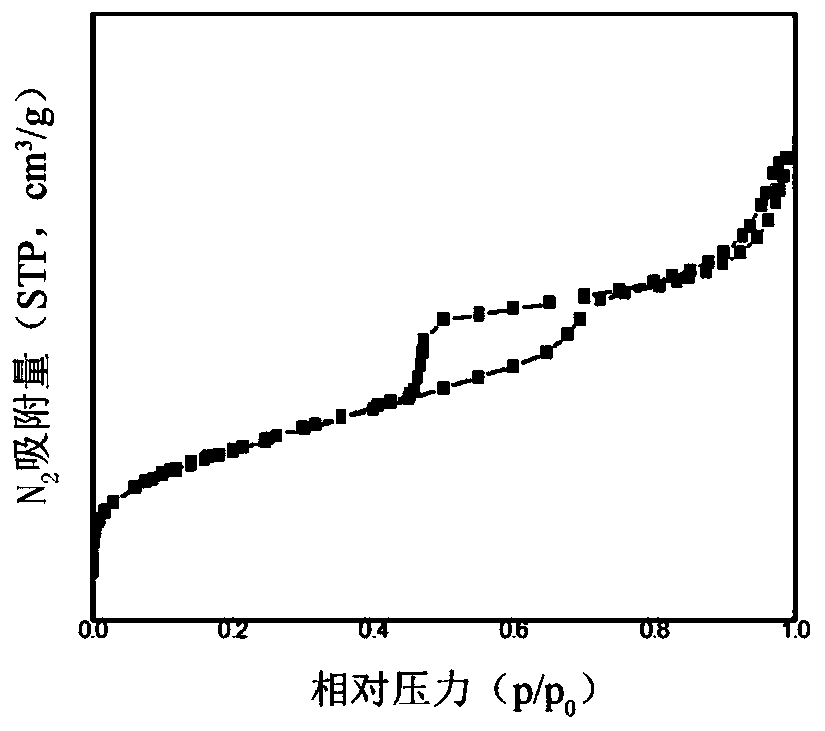

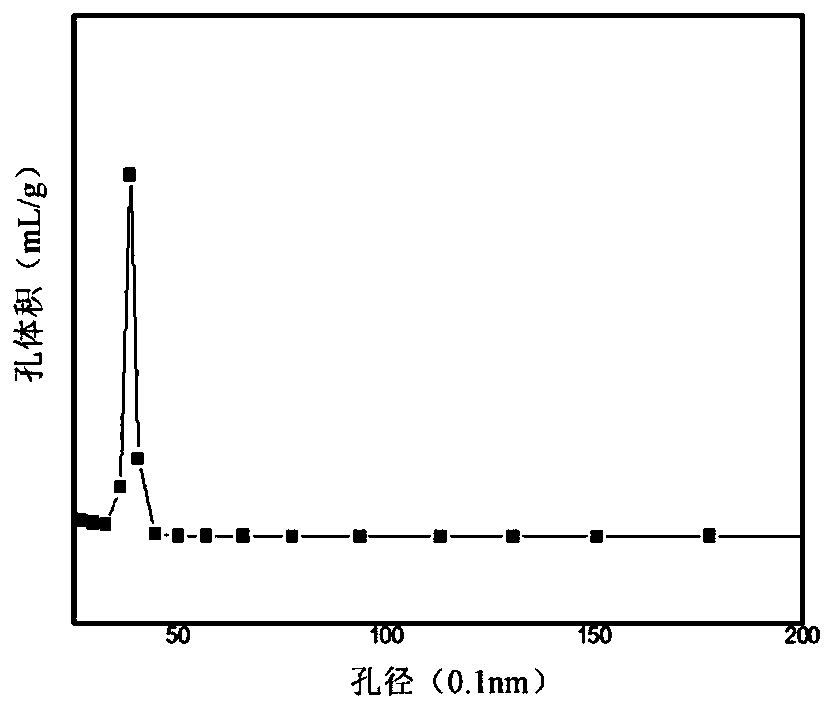

[0085] (1) Preparation of hexagonal mesoporous material carrier

[0086] 2g (1.4×10 -4 mol) template agent F108, 5.24g (0.03mol) of K 2 SO 4Add it to 60g of hydrochloric acid solution with an equivalent concentration of 2 (2N), stir at 38°C until F108 is completely dissolved; add 4.2g (0.02mol) of tetraethyl orthosilicate to the above solution, stir at 38°C for 15min, Stand at 38 ℃ for 24h; then add 100g deionized water to the above mixed solution for dilution, then filter, and wash 4 times with deionized water, then suction filter to obtain the former powder of the hexagonal mesoporous material with a cubic core 1m3m structure; The raw powder with a cube-centered Im3m structure was calcined in a muffle furnace at 400° C. for 12 hours to remove the template agent to obtain the hexagonal mesoporous material A1. Then, the hexagonal mesoporous m...

Embodiment 2

[0102] This example is used to illustrate the non-noble metal-based isobutane dehydrogenation catalyst and its preparation method.

[0103] (1) Preparation of hexagonal mesoporous material carrier

[0104] 1.46g (1×10 -4 mol) template agent F108, 6.96g (0.04mol) of K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 (2N) at 38°C until F108 is completely dissolved; add 3.1g (0.015mol) of tetraethyl orthosilicate to the above solution, stir at 38°C for 15min, and at 40°C Leave standstill 20h; Then add 100g deionized water dilution in above-mentioned mixed solution, then filter, and wash 4 times with deionized water, then suction filtration obtains the former powder of hexagonal mesoporous material with cubic core 1m3m structure; The above-mentioned obtained The raw powder of the hexagonal mesoporous material with a cubic center Im3m structure was calcined in a muffle furnace at 600° C. for 8 hours to remove the template agent to obtain the hexagonal mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com