Mixed matrix cation exchange membrane based on metal organic framework compound and preparation method thereof

A metal-organic framework and cation exchange membrane technology, applied in the field of membrane separation, can solve problems such as insufficient mechanical strength and poor film-forming properties, and achieve the effects of enhancing ion selectivity, increasing porosity, and enhancing ion transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: A preparation method of a mixed matrix cation exchange membrane based on a metal organic framework compound

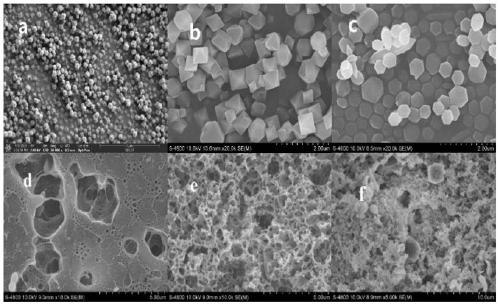

[0023] a. First weigh 0.297g of zinc nitrate hexahydrate solid powder and 0.66g of 2-methylimidazole solid powder and add them to 11.3g of methanol solution respectively, then ultrasonicate the solution at room temperature until hexahydrate After zinc nitrate and 2-methylimidazole were fully dissolved in methanol, the two solutions were quickly mixed and placed on a magnetic stirrer for stirring. After reacting for a period of time, the pre-product of the ZIF-8(Zn) metal organic framework compound can be obtained by filtering. The pre-product is cleaned with methanol. The cleaning method is to soak the pre-product in methanol and continue to stir for 24 hours. The process needs to be carried out three times, and after each cleaning process, the product needs to be centrifuged and replaced with new methanol. After the cleaning process, the final produ...

Embodiment 2

[0026] Example 2: A preparation method of a mixed matrix cation exchange membrane based on a metal organic framework compound

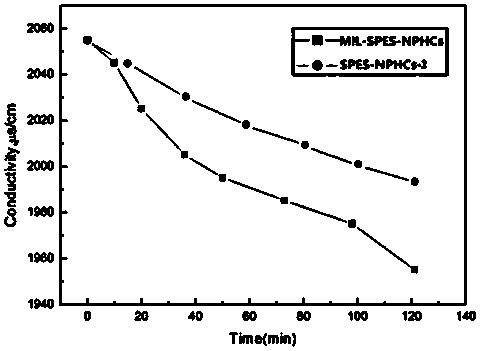

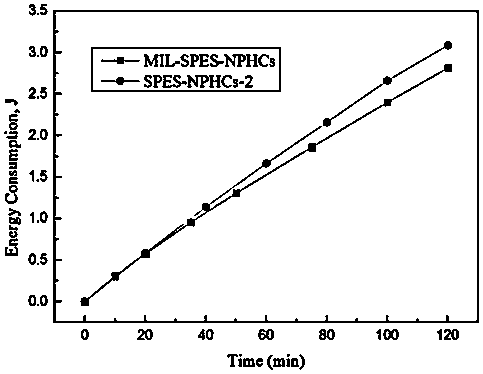

[0027] a. Dissolve 0.1-2g of terephthalic acid in 70-100ml of N / N-dimethylformamide (DMF), then add 0.5-2g of FeCl 3 ·6H 2 O, Stir and dissolve with a magnetic stirrer, then add 2.5-4ml of acetic acid, disperse evenly, put it into the reaction kettle, keep it warm at a temperature of 100-140°C for 18-24h, centrifuge after the reaction, and the obtained solid product Wash three times with DMF and methanol respectively, and finally dry at 60-100°C to obtain a brick-red solid product (Fe-MIL-101) (such as figure 1 Middle b).

[0028] b. Dissolve 3g of phthalic anhydride in 19g of N,N-dimethylacetamide, add 0.7g of chitosan, and heat at 110°C under N 2 Stir and react in the atmosphere, then pour into a large amount of ice water, filter, wash with ether, and dry to obtain phthalylated chitosan. 3.5g polyethersulfone dissolved in 50g chloroform, N 2Und...

Embodiment 3

[0030] Example 3: A preparation method of a mixed matrix cation exchange membrane based on a metal organic framework compound

[0031] a. Weigh 0.233g of zirconium tetrachloride solid powder and 0.166g of terephthalic acid solid powder into 72ml of N,N-dimethylformamide liquid, and then ultrasonically treat the solution at room temperature until After fully dissolving zirconium tetrachloride and terephthalic acid in N,N-dimethylformamide, the solution was transferred to a stainless steel reaction kettle (100ml) with a polytetrafluoroethylene liner. The reaction kettle was placed in an oven for reaction. The reaction time was 24 hours, and the oven temperature was set at 120°C. The oven needs to be preheated before the reaction. After the reaction, the pre-product of the UIO-66(Zr) metal-organic framework compound is obtained by filtration, and then the pre-product needs to be cleaned and vacuum-dried to remove unreacted terephthalic acid and N that may remain in the pores. N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com