Current control method for double three-phase permanent magnet synchronous motor

A dual-phase permanent magnet, synchronous motor technology, used in motor generator control, AC motor control, electronic commutation motor control, etc. In order to avoid the large current harmonic total distortion rate, reduce the impact, and reduce the total harmonic distortion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments, so as to facilitate a clear understanding of the present invention, but they do not limit the present invention.

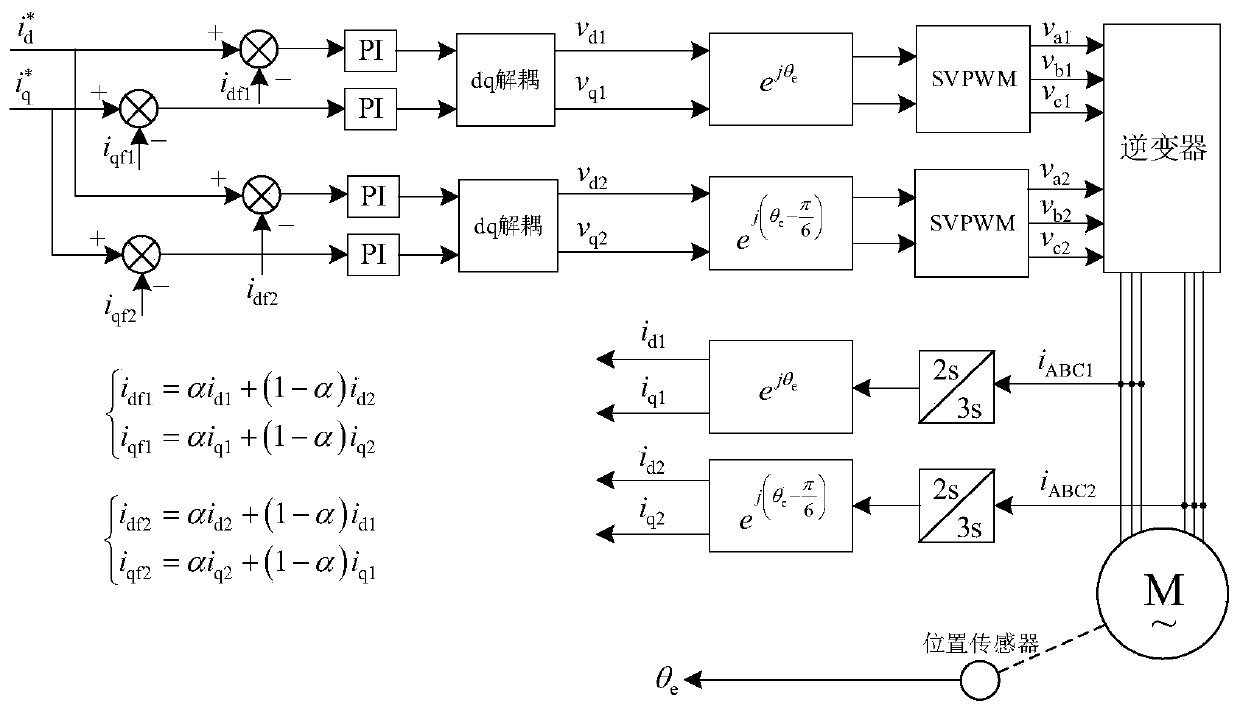

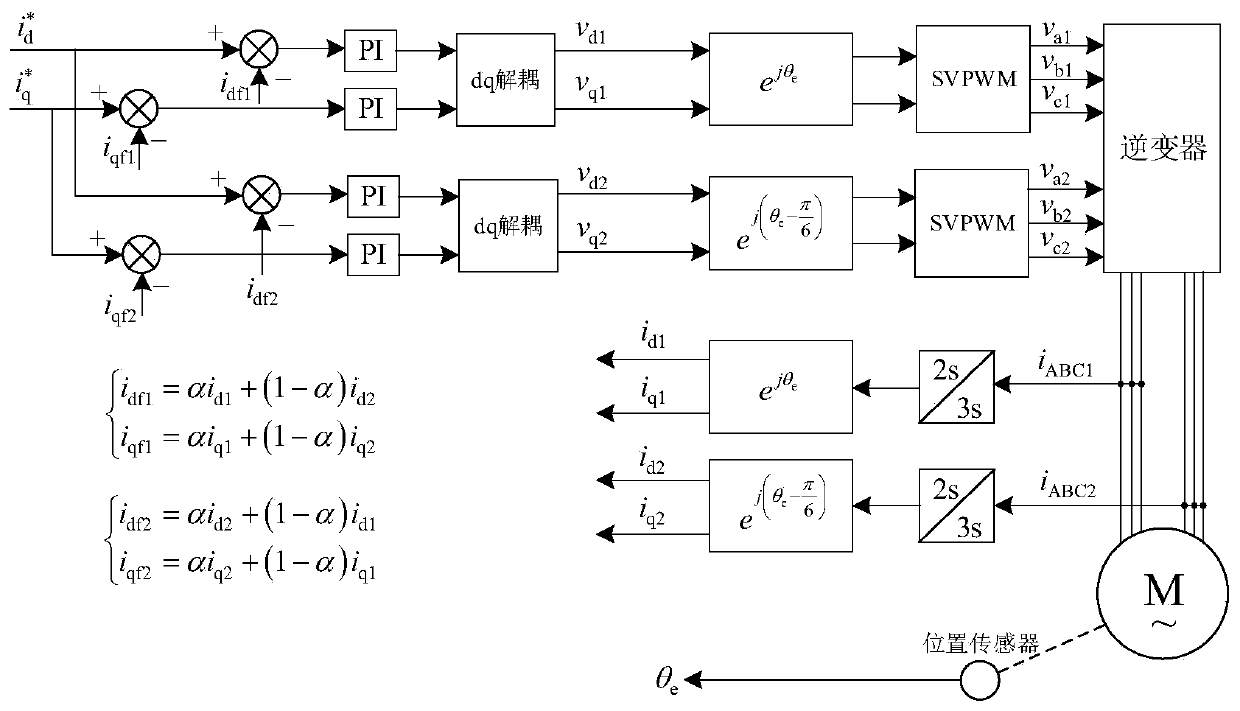

[0024] like image 3 As shown, in the current control strategy of the dual-phase permanent magnet synchronous motor, two sets of rotor synchronous coordinate systems are set, and the second set of rotor synchronous coordinate systems lags behind the first set of rotor synchronous coordinate systems by 30 degrees electrical angle. The vector control of the first set of windings is completed under the first set of rotor synchronous coordinate systems, and the vector control of the second set of windings is completed under the second set of rotor synchronous coordinate systems. The first set of windings has two current regulators, namely the d-axis current regulator and the q-axis current regulator, whose output is decoupled from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com