Cable stripping device and cable stripping equipment

A cable and linear technology, applied in the field of cable stripping, can solve the problem that it is not suitable to use stripping the cable core sheath with different damage degrees, and achieves the effect of small damage, not easy to break, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

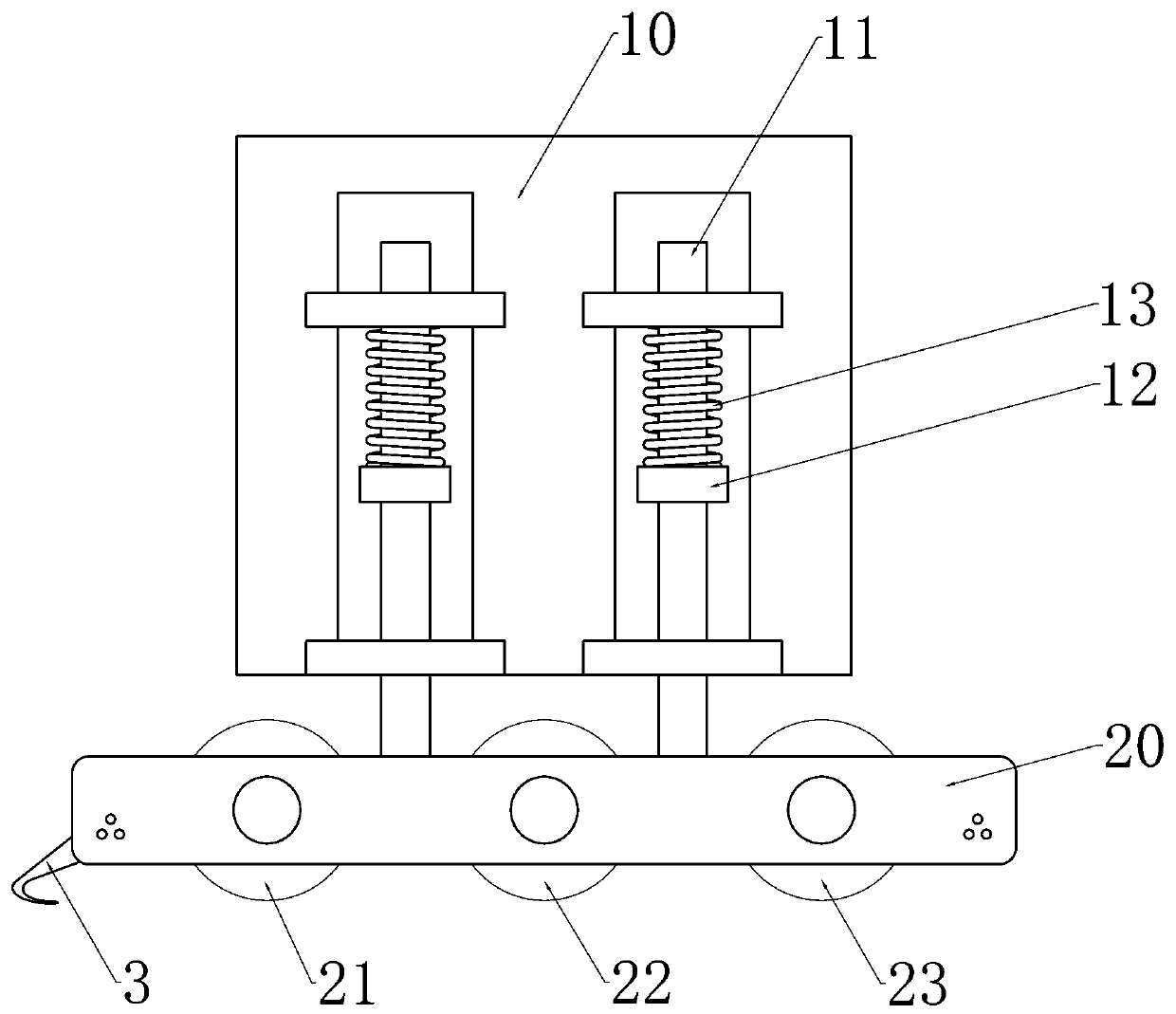

[0046] Embodiment 1: a kind of cable stripping equipment, refer to figure 1 , Figure 5 , including at least two groups of the aforementioned cable stripping devices, these groups of cable stripping devices are used to be arranged at corresponding positions of the cables, so that the traveling wheels can clamp the cables. If the cable stripping equipment has two sets of cable stripping devices, the running wheels of the two sets of cable stripping devices should be respectively arranged on both sides of the cables, so that the running wheels can clamp the cables. If the cable stripping equipment has multiple sets of cable stripping devices, the running wheels of the multiple sets of cable stripping devices should be set in positions so that the running wheels can hold the cables.

[0047] The cutting knife 3 is installed at a corresponding position on the wheel frame 20, so that the cutting knife 3 can cut the sheath of the cable core. Generally, when at least two running wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com