Air cooling and liquid cooling combined battery heat dissipation device and method

A heat-dissipating device and a combined technology, applied in battery circuit devices, circuit devices, secondary batteries, etc., can solve the problems of inability to control the maximum temperature of the battery pack at 50°C, decrease in charge and discharge capacity, and low thermal conductivity, so as to make up for it. The effect of uneven heat dissipation, energy saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

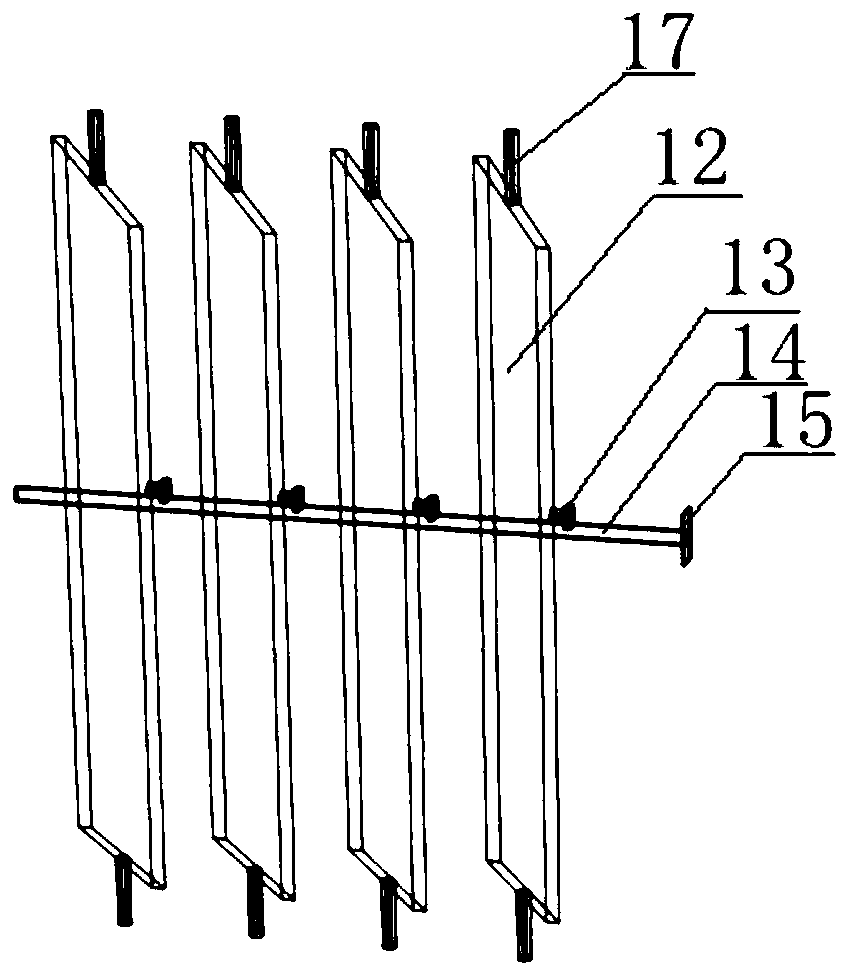

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0023] Such as figure 1 As shown, the heat dissipation device of the present invention includes a battery case 6 , a heat dissipation assembly, a battery module set in the battery case 6 and a BMS (Battery Management System, battery management system) installed in the battery case 6 .

[0024] A number of single cells 5 with battery covers in the battery case 6 are arranged in a rectangular array to form a battery module. The lower part of the battery case 6 is provided with a substrate 1 for placing the battery module; the surface of the substrate 1 is not in contact with the single cells. 5 The contact part is provided with several through holes to facilitate heat dissipation. The cooling assembly includes an exhaust fan 2, a temperature sensor 3, a two-way S-shaped su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com