Tunnel building method capable of penetrating through rockburst section

A technology for tunnels and sections, applied in the field of tunnel construction through rock burst sections, can solve problems such as intensifying the tendency and uncertainty of rock burst occurrence, aggravating stress concentration, dissipating rock burst energy, etc., so as to reduce damage and disturbance, The effect of enhancing punching shear resistance and reducing stress concentration in surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

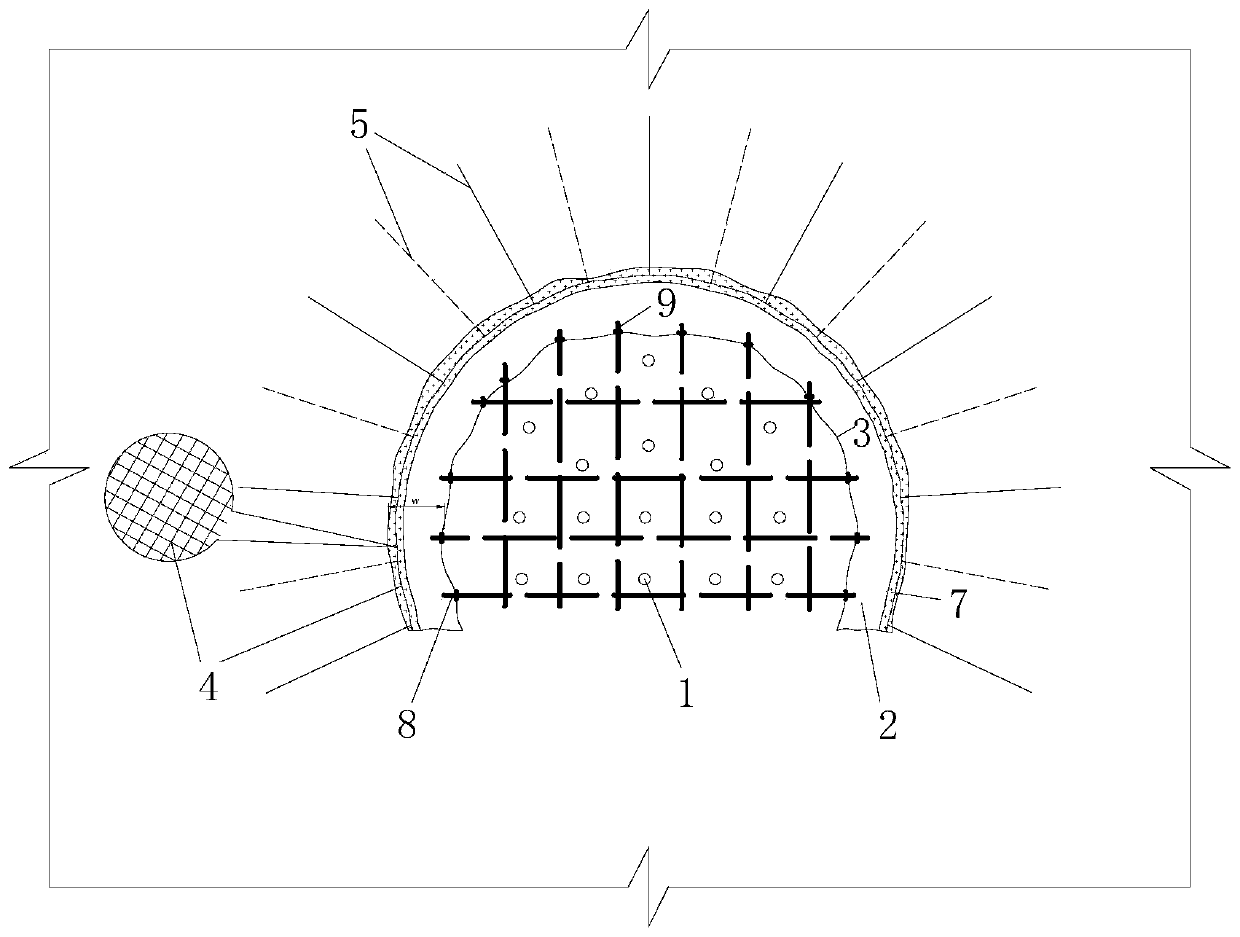

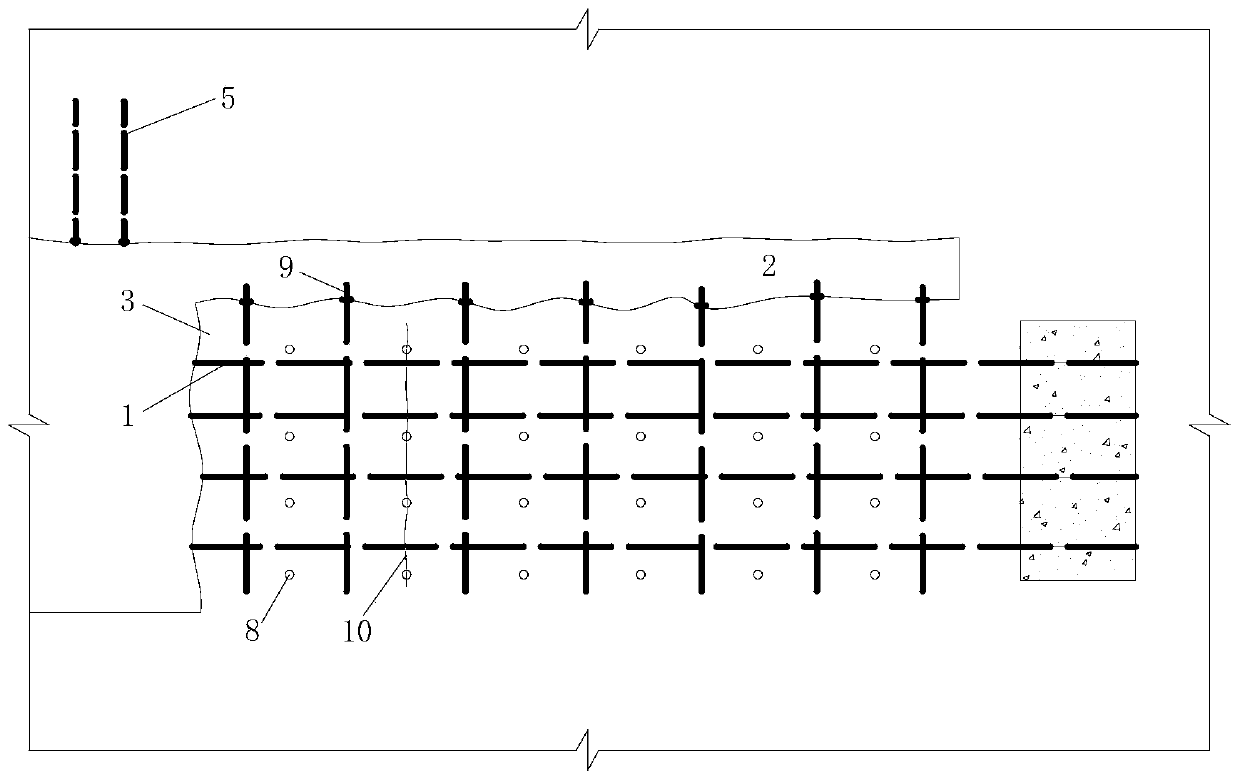

[0034] See Figure 1-2 , The present invention discloses a tunnel construction method for crossing a rockburst section, which is carried out as follows:

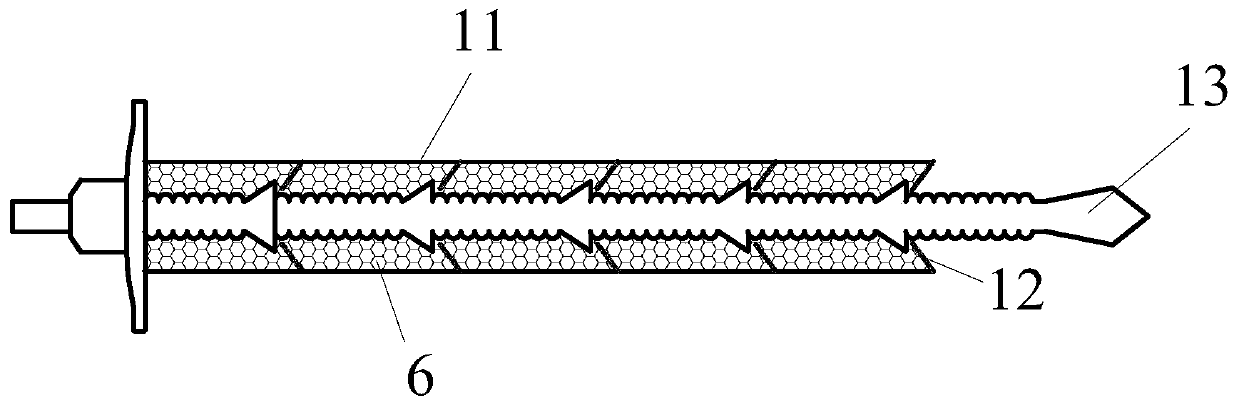

[0035] Step 1. Apply a large hollow bolt 1 to the face of the tunnel to control the tunnel face rockburst, the length of the bolt is 9m, the anchor end is 3m, and the remaining length is left blank for burying the blasting charge;

[0036] Step 2. Use pre-split blasting to blast a 0.8m excavation slot 2 along the tunnel outline. The longitudinal slot length of the tunnel is always 6m ahead of the tunnel face, and the core surrounding rock 3 is retained;

[0037] Step 3. After the slag is discharged, steel arches and steel mesh 4 are constructed, new energy-consuming anchors 5 are laid, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com