A liquid nitrogen circulation cold shock anti-reflection method based on multi-parameter monitoring

A multi-parameter, cold shock technology, applied in the direction of surveying, earthwork drilling, wellbore/well components, etc., can solve the problem of low effective pressure and flow rate, increasing the time required for coal seam anti-reflection, and the inability to guarantee the effect of anti-reflection, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below.

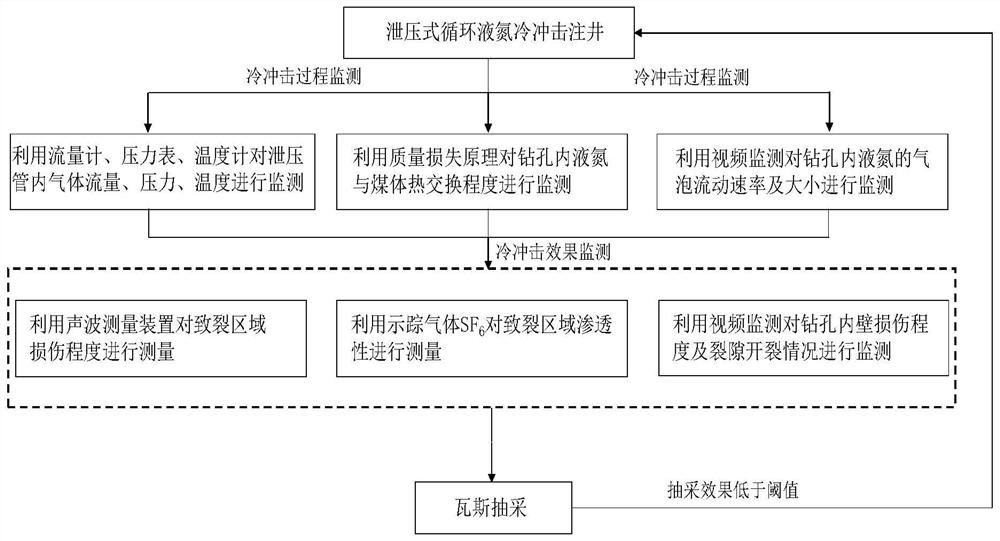

[0024] Such asfigure 1 and figure 2 Shown, concrete steps of the present invention are:

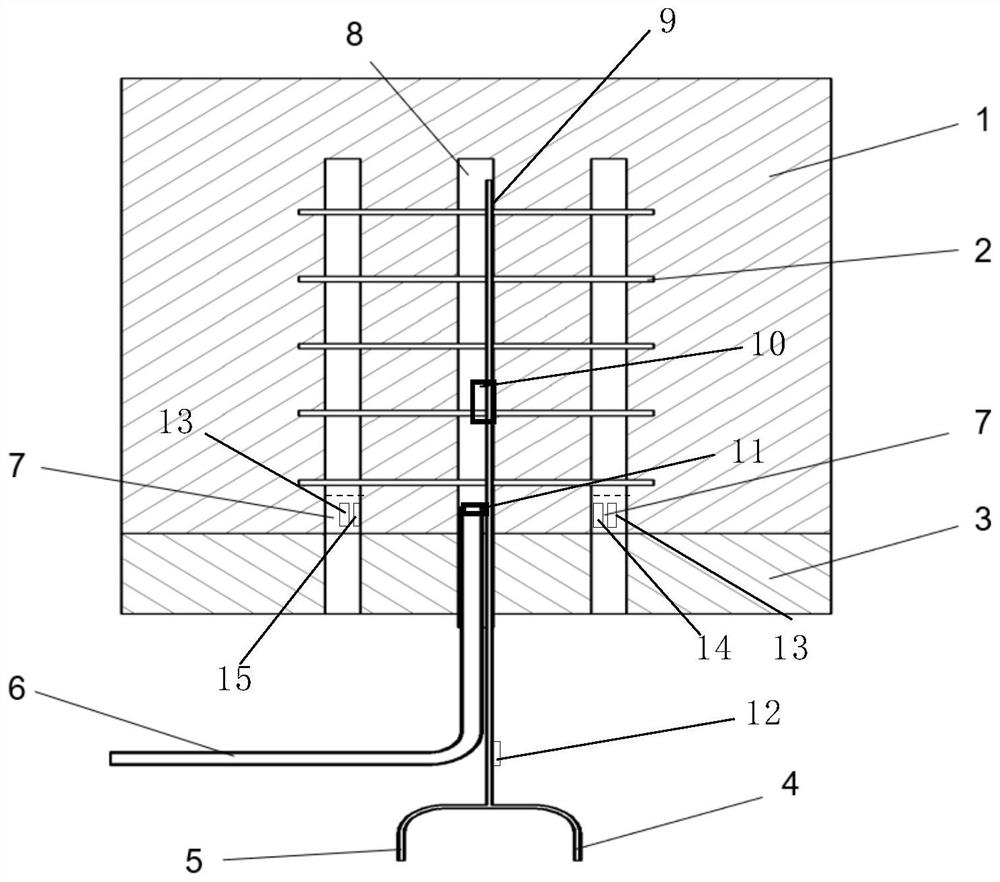

[0025] A, set a layer-penetrating borehole 8 in the roadway, and the borehole passes through the rock formation 3 and extends into the coal seam 1;

[0026] B. Use hydraulic slotting equipment to extend into the seam-penetrating borehole 8 to reach the coal seam 1, and cut out a plurality of discs at equal intervals in the coal seam 1 with the seam-penetrating borehole 8 as the center along the direction perpendicular to the seam-penetrating borehole 8 crack 2;

[0027] C. Extend one end of the liquid nitrogen injection pipe 6 and one end of the pressure relief pipe 9 into the layer-penetrating drilling hole 8 to reach the coal seam 1, and the liquid nitrogen injection pipe 6 is equipped with a video monitoring lens 10 with a light source; then the layer-penetrating drilling hole 8 The rock formation section is sealed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com