A coal seam permeability enhancement method using liquid nitrogen cold shock and phase change gas circulation damage

A technology of gas circulation and cold impact, which is applied in the direction of mining fluid, earthwork drilling, borehole/well valve device, etc. It can solve the problem of low effective pressure and flow rate, poor stability, and the time required to increase the permeability of coal seams, etc. problems, to achieve the effect of improving the cracking effect and widening the cracking area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below.

[0018] Such as figure 1 Shown, concrete steps of the present invention are:

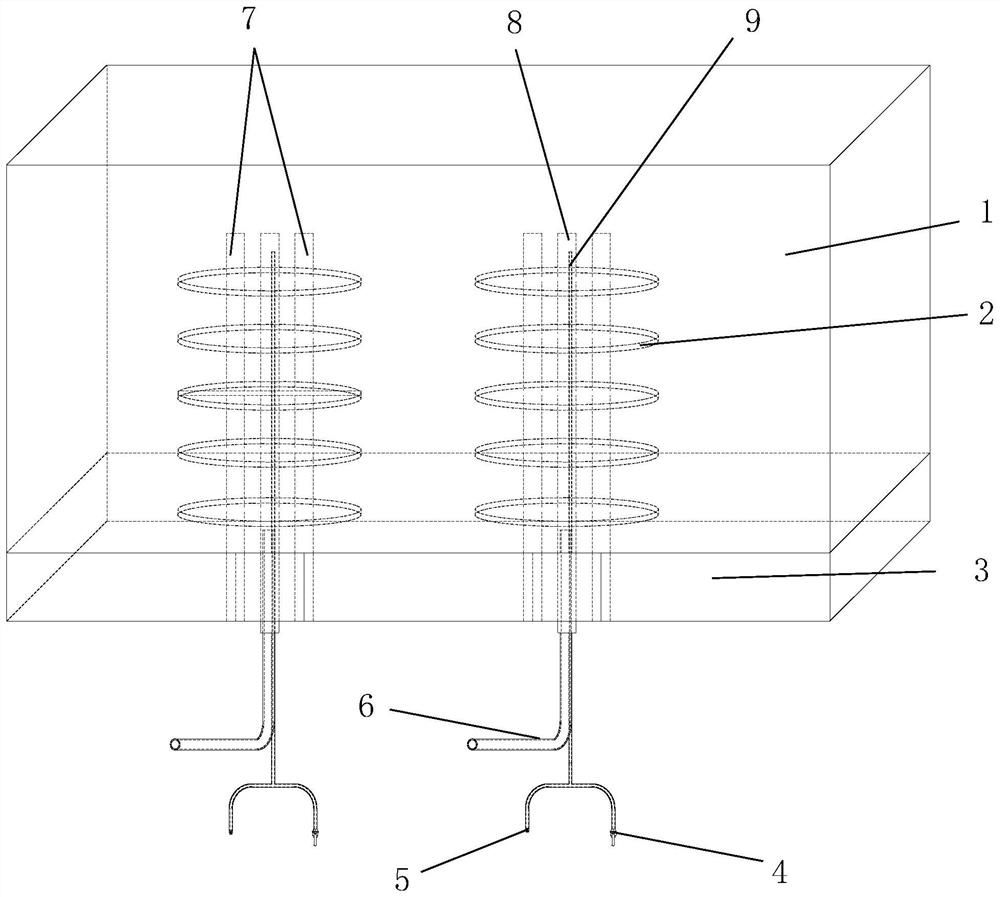

[0019] A. Set up two layer-penetrating boreholes 8 in the roadway, and the two boreholes pass through the rock formation 3 and extend into the coal seam 1;

[0020] B. Use hydraulic slotting equipment to extend into the seam-penetrating borehole 8 to reach the coal seam 1, and cut out a plurality of discs at equal intervals in the coal seam 1 with the seam-penetrating borehole 8 as the center along the direction perpendicular to the seam-penetrating borehole 8 Crack 2: used to fully contact the coal body after liquid nitrogen injection to achieve a better effect of fracturing and increasing permeability;

[0021] C. Extend one end of the liquid nitrogen injection pipe 6 and one end of the exhaust pipe 9 into the layer-penetrating drilling hole 8 to reach the coal seam, and then seal the liquid nitrogen injection pipe and the exhaust pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com