Ice layer pore wall coring system and method

A hole wall and coring technology, which is applied to drilling equipment and methods, devices for extracting undisturbed cores, and earthwork drilling and mining, can solve the problems of difficult on-site operation and inconvenience in taking ice cores, and achieves simple, efficient and efficient coring methods. The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

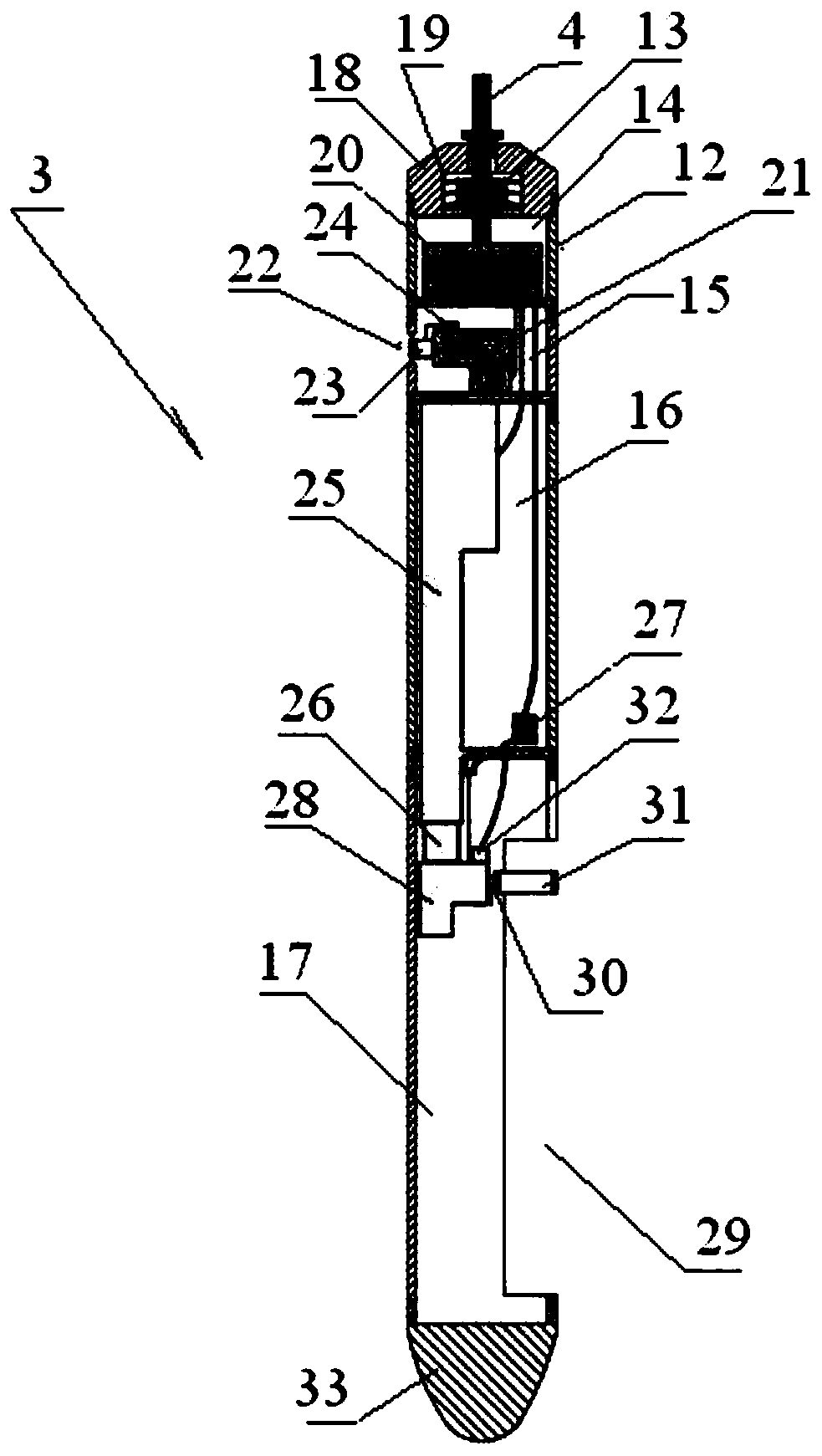

[0045] see Figure 1 to Figure 11 Shown:

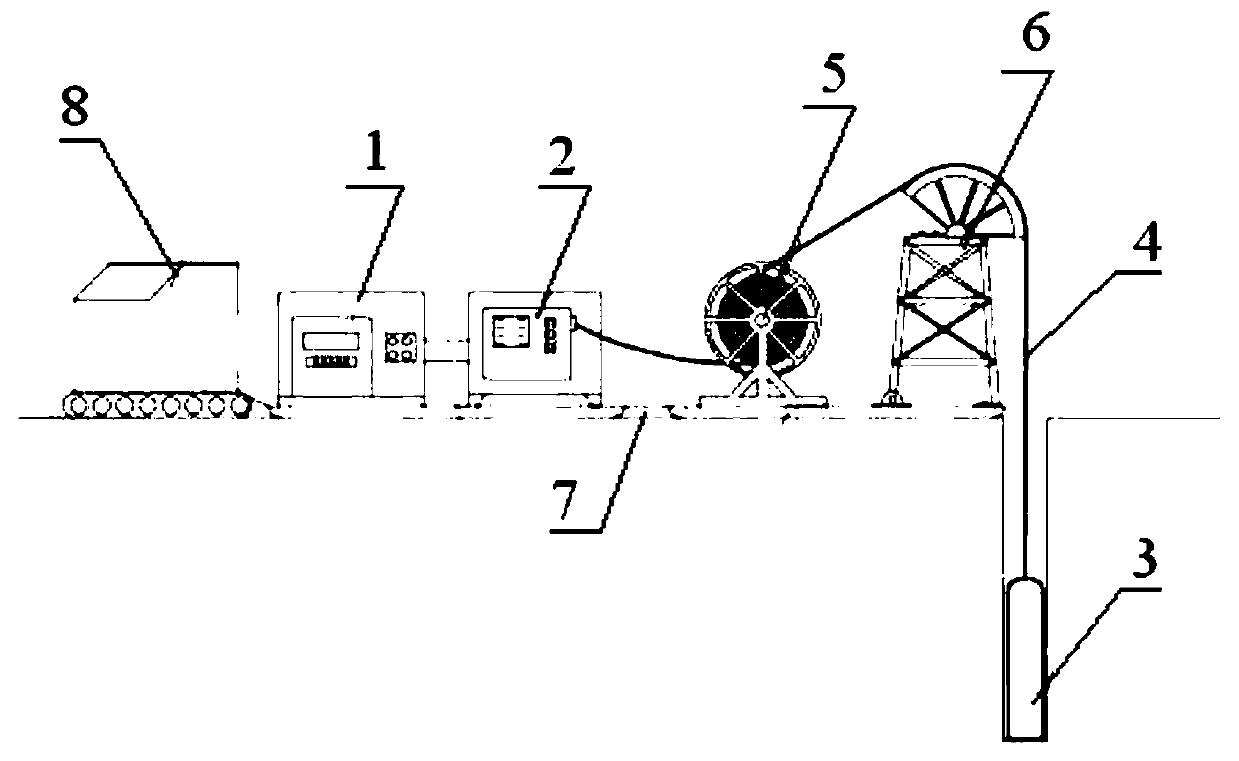

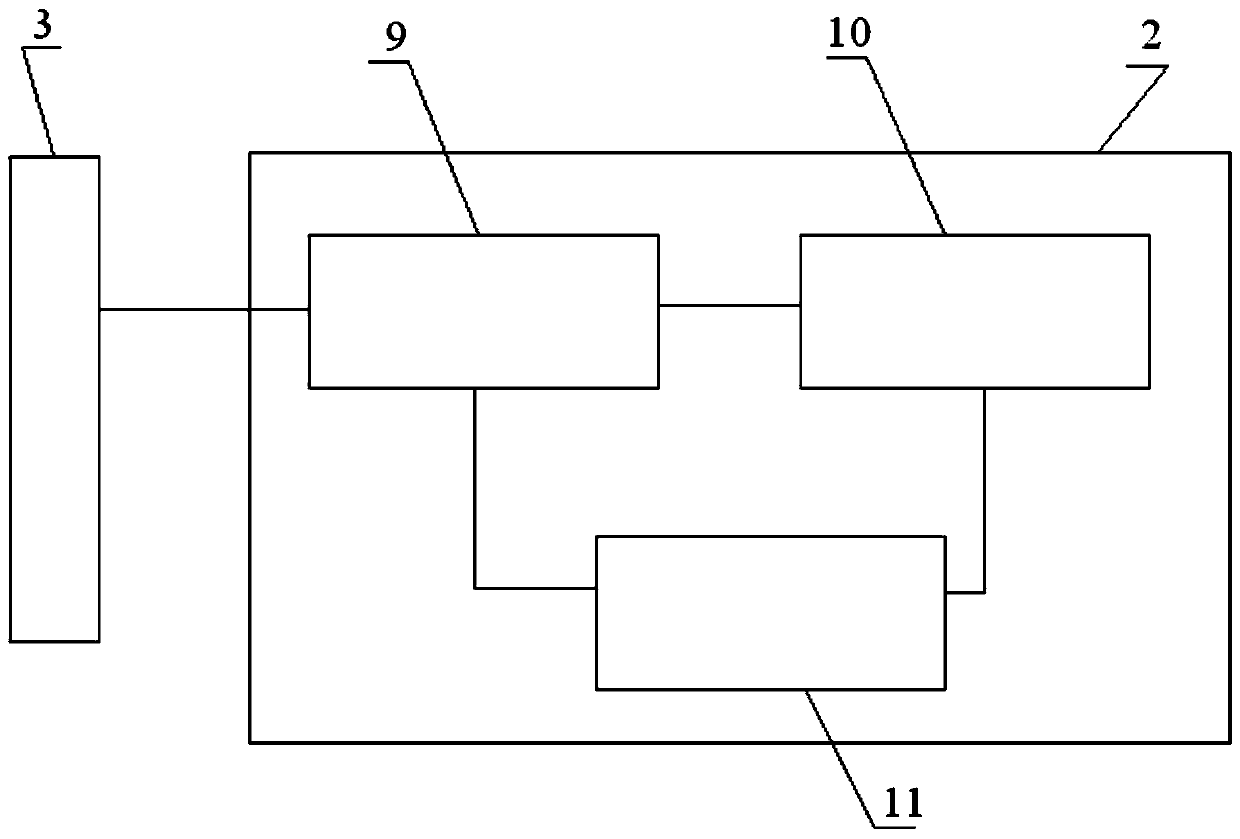

[0046] The ice hole wall coring system provided by the present invention includes a generator 1, a surface control system 2 and a hole wall coring drill 3, wherein the generator 1 is connected with the surface control system 2, and the surface control system 2 is connected through an armored cable. 4 is connected with the hole wall core drilling tool 3, the generator 1 provides power for the hole wall core drilling tool 3 through the surface control system 2, and the surface control system 2 controls the work of the hole wall core drilling tool 3.

[0047] The armored cable 4 connecting the surface control system 2 and the hole wall core drilling tool 3 is wound on the drawworks 5, and a guide frame 6 is arranged between the drawworks 5 and the hole wall core drilling tool 3, and the armored cable 4 passes through the guide The frame 6 is connected with the core drilling tool 3 on the hole wall, the generator 1, the surface control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com